Digital manufacturing service provider Protolabs has introduced Design for Manufacturability (DFM) analysis for 3D printed parts, providing what the company claims to be a “peace of mind” for manufacturers throughout Europe.

According to the company, it is a progressive step to the 3D printing offering because it offers additional assurance that a part is ideal for manufacturing before committing to production, all online in a few seconds. Andrea Landoni, Protolabs EMEA’s 3D Printing Product Manager said, “The Design for Manufacturability analysis supports our Application Engineers by reducing the number of projects they need to get involved in, allowing them to interact with more customers who require their support even faster.”

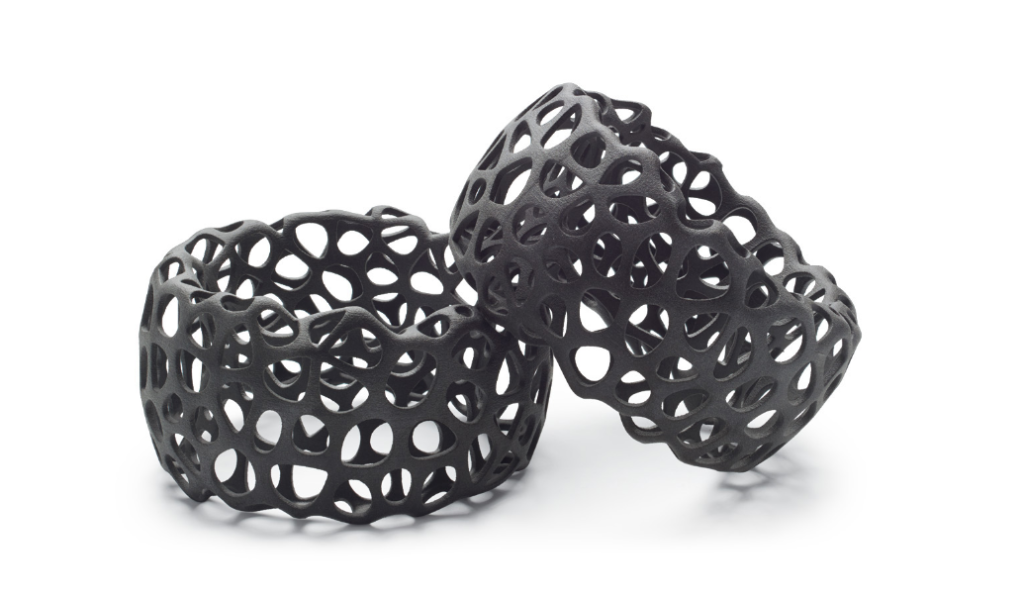

“Additive manufacturing is a brilliant technology, allowing engineers to produce complex parts that were previously too difficult to achieve, added Landoni.

What was the motivation behind creating this novel technology?

Landoni went on to say that Protolabs acknowledges that certain projects necessitate technical assistance to resolve complex problems. In such instances, its application engineers are still available to help overcome these roadblocks and speed up the process.

DFM processes nullify lost time instances for the majority of common problems, avoiding engineers from completing orders only to find an issue hours later. While the vast majority of issues are fixed, there may be times when the user requires additional assistance.

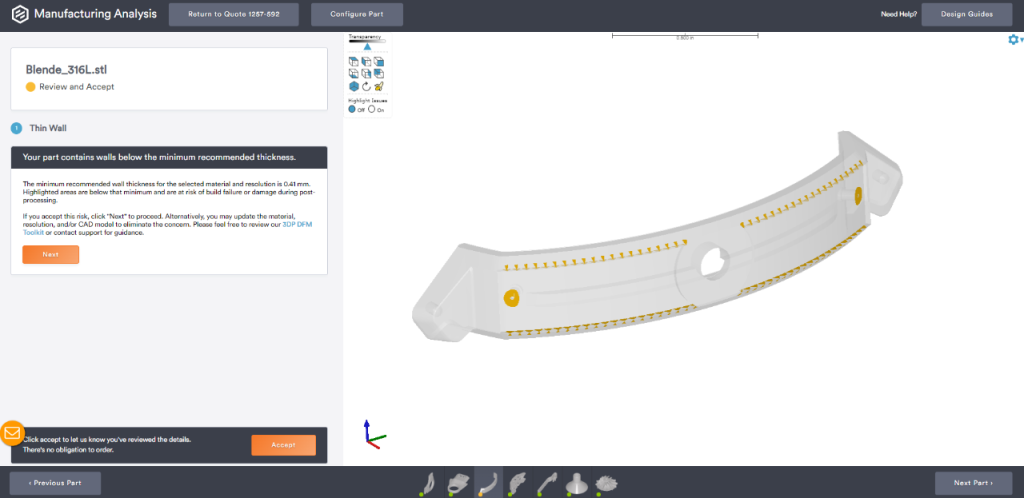

Although the technology offers superior flexibility, engineers must be aware of a few constraints, and the DFM analysis offers ideal solutions in seconds, claims the company. The system will immediately alert the user to any issues, which can be critical, like components that are too huge to be manufactured, or non-critical, such as dimensions that are near certain thresholds, like wall thickness, and might not form completely.

“We understand the importance of speed, but ensuring that parts are correct, high quality, and delivered rapidly is critical. Instant analysis means you can have all the advantages of additive manufacturing with even more certainty without sacrificing speed,” stated Landoni.

Why do AM companies choose to advance DFM?

Previously, San Francisco-based manufacturing bureau Fictiv added 3D visualization to its injection molding DFM system. According to Fictiv, its Digital Manufacturing Ecosystem (DME) offers high-quality components at an unprecedented rate. The improved software, as per Fictiv, facilitates comprehensive automation of injection molding processes, enabling clients to expedite new product design while reducing manufacturing risks and delays. This enhanced system incorporates digital manufacturing issue tracking, part version control, and communication tools. 3D visualization also substantially improves the speed with which engineering teams can demand, evaluate, and respond to injection molding DFM input, as well as approve components for production.

Elsewhere, with its Instant Quote Platform, China-based rapid-prototyping company RapidDirect attempted to fill the void between physical and digital production systems for rapid prototyping and on-demand manufacturing. RapidDirect’s instant quote platform offers a consumer-friendly interface, DFM analysis, and effective order management to address the problem areas of rapid prototyping, like effectiveness, pricing, lead times, and a lack of transparency in the manufacturing process. RapidDirect’s instant quote platform, in essence, provides customers with full access to a broad range of prototyping and on-demand manufacturing services, reducing the planning stage from days to less than a minute. Moreover, the platform allows users to download, oversee, and modify quotes in a single location, reducing turnaround times, increasing efficiency, and saving money.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows automated DFM process user interface. Image via Protolabs.