Metal 3D printing specialist 3DEO has secured an investment from the Development Bank of Japan (DBJ) and Seiko Epson Corporation (EPSON).

DBJ and EPSON’s investment aligns with DBJ’s objective to promote technological innovation and industry reorganization. While the details have not been disclosed, this collaboration harmonies with Epson’s mission to encourage manufacturing innovation under its Epson 25 Renewed Corporate Vision. Facilitated through the DBJ Startups and Innovation Fund, the investment is expected to facilitate 3DEO’s business expansion in North America and Japan.

“By integrating 3DEO’s AM capabilities with the meticulous engineering tradition of Japan, we aim to unlock new levels of productivity and expand the manufacturing possibilities in one of the world’s leading economies,” said Payman Torabi, CTO and Co-founder of 3DEO. “This investment is a testament to the trust and potential seen in 3DEO’s innovative approach. We are excited to collaborate with DBJ and Epson, leveraging their expertise and market reach to enhance and refine the landscape of Additive Manufacturing.”

Tackling challenges and adopting AM in a global landscape

In Japan, where traditional metalworking practices like precision casting have been prevalent, there is a growing interest in exploring AM technologies and design for additive manufacturing (DfAM). This collaboration with 3DEO aims to address the challenges hindering the adoption of these technologies in the country’s manufacturing landscape.

The investment underwent a thorough review by the Committee on Foreign Investment in the United States (CFIUS) before being finalized. This strategic move positions 3DEO to capitalize on the strengths of the Japanese manufacturing industry while contributing to technological advancements in both North America and Japan.

Working closely with Epson and other stakeholders, DBJ will play a hands-on role in supporting 3DEO to assist in building the company’s business and increasing its corporate value. Additionally, DBJ aims to serve as a liaison for all involved parties, including national and local governments and related private companies, fostering the social implementation of DfAM in Japan and supporting innovation and restructuring in the manufacturing sector.

“The collaboration with DBJ and EPSON is a powerful endorsement of our mission to empower product and engineering teams across the globe,” said Matthew Petros, CEO and Co-founder of 3DEO. “This investment is not just capital; it’s a commitment to a shared vision of challenging what’s possible through the combination of additive design principles and differentiated capabilities.”

3DEO’s additive manufacturing expertise in retrospect

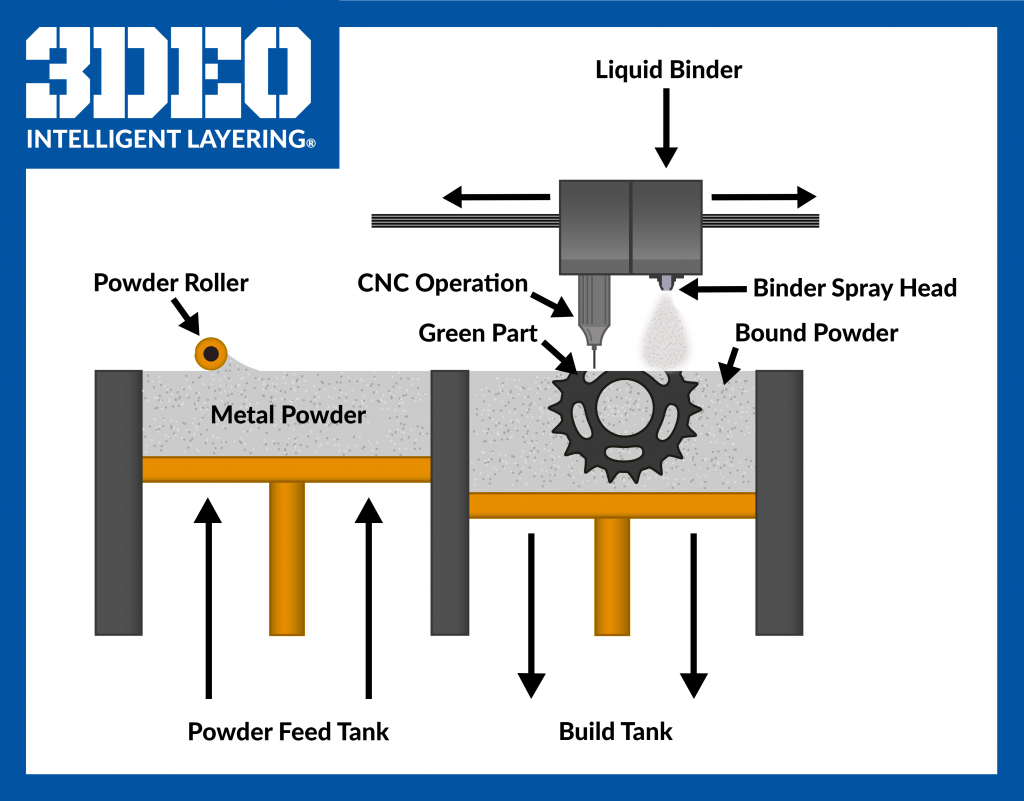

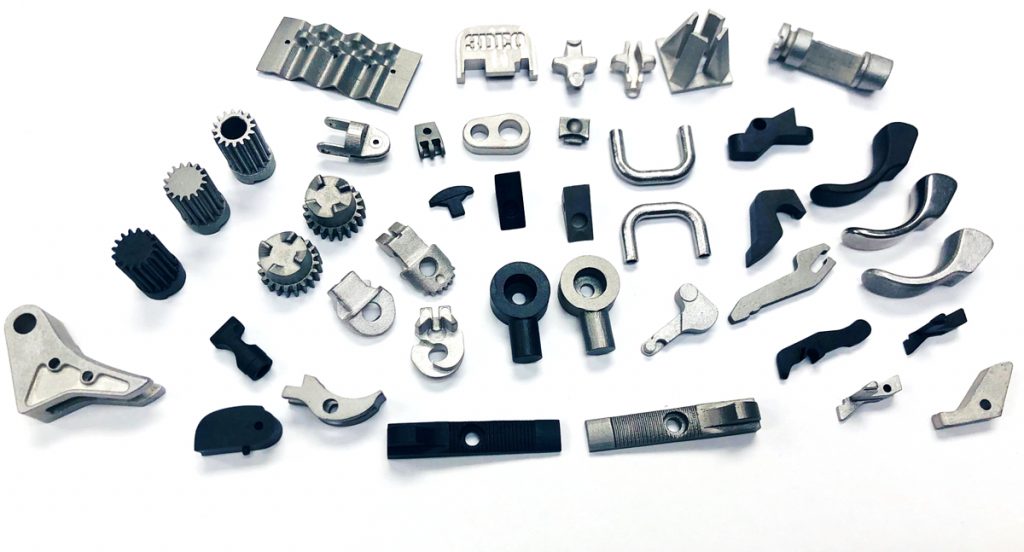

Since its inception in 2016, 3DEO has utilized its proprietary Intelligent Layering technology for cost-effective, high-volume production meeting Metal Injection Molding standards. The technology ensures superior surface quality, cost efficiency, and fine features in metal components, catering to medical, defense, and aerospace markets.

In August 2020, 3DEO won the 2020 Design Excellence Award for its steel anchor link, highlighting advancements in technology and design. Months before the award, 3DEO announced a triple-digit annual growth in its business metrics for 2019, with approximately 40% of its customers in the defense industry, 35% in medical, and 25% in aerospace.

Last year in 2023, 3DEO launched 316L stainless steel, a fully austenitic, non-magnetic alloy (similar to UNS S31603) with superior ductility and mechanical characteristics at space and higher temperatures. This highly corrosion-resistant, weldable material is suitable for harsh environments.

Driving progress through strategic AM investments

Investments in the additive manufacturing sector play a vital role in shaping a future where 3D printing disrupts traditional industries and accelerates bespoke production possibilities in the fields of aerospace to healthcare. As a result, it provides customized solutions through streamlined and adaptable production methods. For instance, German fluid-dynamic metrology device developer Vectoflow secured €4 million in a Series A investment round, attracting support from investors like Bayern Kapital Innovationsfonds II, AM Ventures, and Schwarz Holding.

Specializing in aerospace and energy instrumentation, Vectoflow plans to use the funding to expand into serial production and pursue global growth through collaborations. With an emphasis on leveraging existing customer trust for expansion into aerospace and wind energy applications, the company’s focus on additive manufacturing, sensor calibration, and software development positions it for advancements in fluid-dynamic metrology devices.

In another news, the healthcare sector also saw a boost with Dimension Inx raising $12 million in funding to accelerate organ regeneration therapeutics development and expand manufacturing capabilities. The company’s first 3D printed restorative bone graft product, FDA-cleared CMFlex, streamlines clinician workflow, reduces surgical case time, and restores healthy bone. The investment supports CMFlex’s commercial release, showcasing a unique approach that combines biology, material composition, microstructure, and macro architecture to restore bodily functionality.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a collection of small metal parts 3D printed by 3DEO. Photo via 3DEO.