German fluid-dynamic metrology device developer Vectoflow has completed a Series A investment round, securing €4 million in funding.

Investors such as Bayern Kapital Innovationsfonds II, WN Invest, asto One Investment, argo vantage, Schwarz Holding, Dr. Rolf Pfeiffer, along with existing seed investors AM Ventures, and KfW Bankengruppe, provided financial backing to Vectoflow. Focusing on tailored instrumentation for aerospace and energy, the capital raised will fuel Vectoflow’s expansion into serial production. Additionally, the company aims for global growth through new collaborations.

Johann Oberhofer, Managing Partner of AM Ventures, said, “We are proud of having supported Vectoflow from its early stage. Katharina Kreitz and Christian Haigermoser recognized that industrial 3D printing is predestinated for fluid-dynamic metrology devices due to its freedom of design allowing very complex structures. The fact that Vectoflow’s customers are now directing their attention towards series production projects underscores the expertise they have diligently cultivated over the years in the R&D sector. With both existing and new partners on board, we are looking forward to support their further development and growth into series manufacturing.”

Vectoflow’s flight into aerospace and energy frontiers

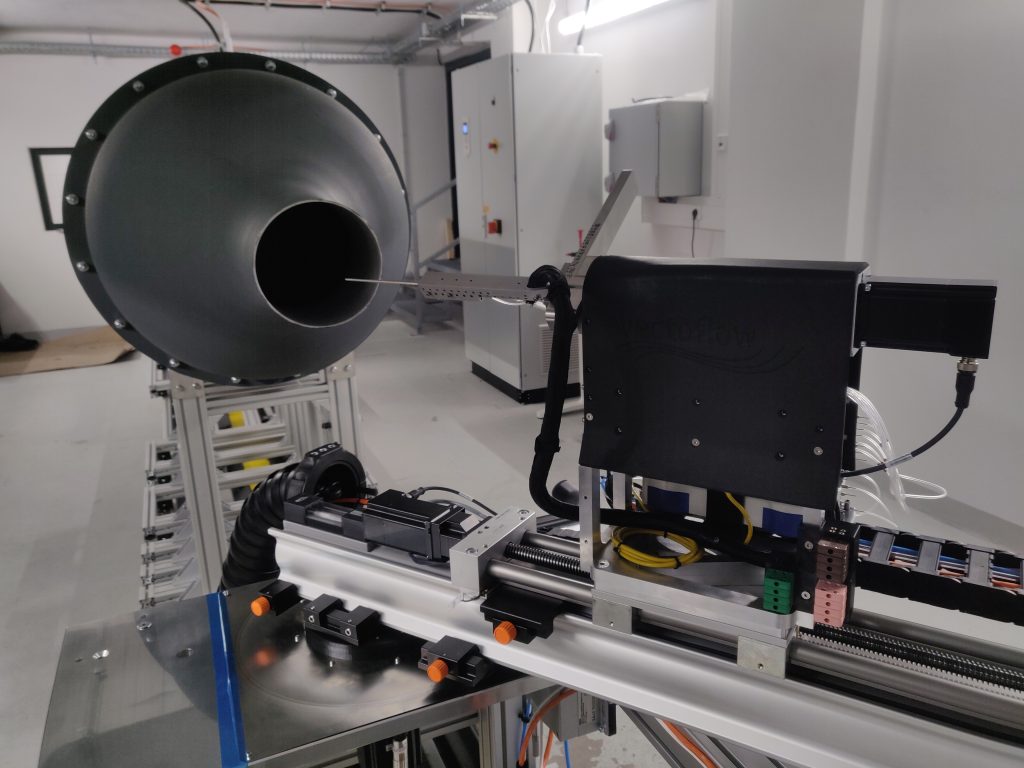

Christian Haigermoser, Co-Founder and Co-CEO of Vectoflow, detailed the strategic areas of growth, focusing on strengthening in-house capabilities. This includes efforts in additive manufacturing, part post-processing, instrumentation assembly optimization, sensor calibration improvement, and the development of software solutions for test rig data acquisition and control. Haigermoser emphasized the crucial role of Vectoflow’s extensive know-how in supporting business development across various markets.

Katharina Kreitz, Co-Founder and Co-CEO, underscored the importance of leveraging existing customer trust for growth. She expressed enthusiasm about ventures into aerospace and wind energy applications, emphasizing their societal relevance as future markets. Kreitz highlighted the trust built among current customers, which the company plans to leverage for expansion into both existing and new markets.

In September 2019, Vectoflow alongside Aerosint, and Fraunhofer IGCV secured a €750,000 Eurostars grant for a 30-month project. Utilizing laser powder bed fusion (LPBF) technology, the consortium aims to develop multi-functional airflow sensors. Aerosint’s powder recoater, Vectoflow’s flow probe expertise, and Fraunhofer IGCV’s multi-metal co-processing will create ‘smart’ fluid flow probes with optimized geometries. The project addresses challenges in multi-material additive manufacturing for enhanced functionality in aviation applications.

Recent Investment in 3D printing companies

3D printing software firm Ai Build secured $8.5 million in a Series A round led by IQ Capital, and others with strategic investment from Nikon. The funds will fuel product development for increased automation and AI capabilities in industrial 3D printing. Ai Build aims to expand into North America, establish a US subsidiary, and continue its growth in Europe. Ai Build‘s AiSync software, utilizing AI and machine learning, streamlines additive manufacturing, making it more accessible. Major firms like Boeing and Weir Group already use Ai Build’s software, reporting significant improvements in additive manufacturing workflows.

Illinois-based 3D printer manufacturer Azul 3D raised $15 million in a Series A funding round, with contributions from existing and new investors, including DuPont. The funds will advance technology development for high-value applications, focusing on manufacturing specialized electronic components and custom devices using Azul 3D‘s High-Area Rapid Printing (HARP) technology. HARP, a proprietary vat polymerization process, employs UV light to create precise, thermally controlled objects from liquid plastic.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Vectoflow Team. Photo via Vectoflow.