Over the past few years, volatile organic compound (VOC) emissions, a bi-product of the FFF process, have been the subject of several studies. In 2017, a study funded by SajTom Light Future Ltd., in Poland, concluded that with adequate ventilation, the melting of materials like ABS, PLA, PET, and nylon does not cause harm to its users.

Findings from a two-year investigative report from UL have also found that exposure to particles and VOC emissions produced by 3D printing processes are generally low when applying appropriate precautions.

Now, scientists from the U.S. Environmental Protection Agency (EPA) are studying VOC emissions from ABS filament that contains carbon nano fiber reinforcement. Again, the same rules surrounding adequate ventilation would apply in this case, but through collaboration with the Consumer Products Safety Commission (CPSC) and the National Nanotechnology Initiative (NNI), the EPA team are seeking to provide a detailed update to the literature on this topic.

3D printing nanomaterials

EPA’s researche is exploring the unique chemical and physical features of nanomaterials, including size, shape, chemical composition, and stability, to help develop predictive models determining which may pose a higher probability of risk. As stated by the EPA, such nanomaterials are in more than 1,300 commercial products such as medical equipment, textiles, fuel additives, and cosmetics.

In order to understand the human and environmental health implications of nanomaterials, commercially available ABS filament was used with a Lulzbot TAZ 3D printer to determine how VOC emissions changed. In doing so, VOC emissions were quantified and characterized by carbon nanotube filaments (CNT) under a variety of conditions to simulate the different heating, melting, and forming of plastics during 3D printing.

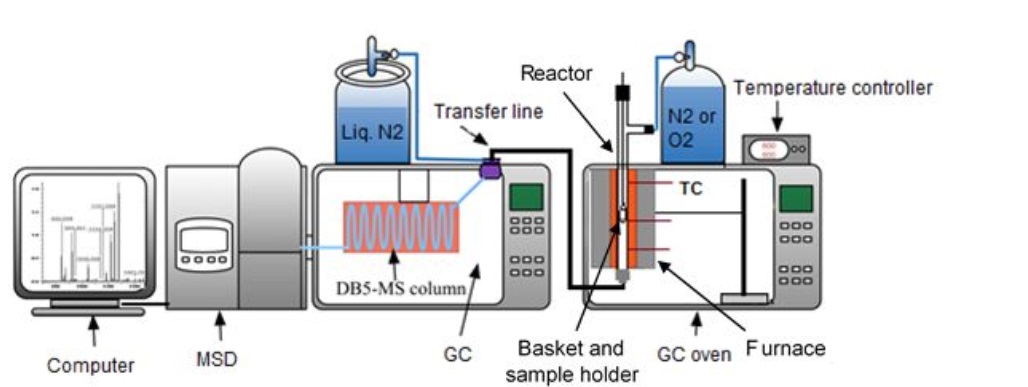

Dr. Al-Abed’s team carefully considered the temperature, length of time the material was heated, and oxygen concentration at the nozzle. These factors were replicated inside a customized reactor and mass spectrometer, otherwise known as a System for Thermal Diagnostic Studies (STDS), to identify combustion-related emission.

Trapping VOC emissions

A comparison was made between the VOC emissions from the CNT infused filament and the ‘plain’ ABS filament. The team found that the material with CNT emitted two new VOC gasses which could potentially pose an inhalation hazard to users 3D printing several kilograms of material.

Furthermore, the researchers concluded that increased print temperature had the most significant effect on increasing VOC emissions, followed by the increased length of time heating the material. CNT also demonstrated the ability to ‘trap’ certain VOC gasses in particulates of 3D printed plastic.

The study notes that the researcher’s instruments could not directly measure these particulates, thus, further investigations will be needed to understand their potential impacts on human health.

For further reading on these findings “VOC Emissions and Formation Mechanisms from Carbon Nanotube Composites during 3D Printing” can be found online inEnvironmental Science & Technology journal.It is co-authored by Phillip M. Potter, Souhail R. Al-Abed, Dean Lay, and Slawomir M. Lomnicki.

For more news additive manufacturing news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows FFF/FDM 3D printing. Photo via the U.S. EPA.