A study funded by SajTom Light Future Ltd., a privately held entity headquartered in Poland, has looked into the emissions produced by common 3D printer filaments ABS, PLA, PET, and nylon.

The research supports an extensive body of research proving that, with adequate ventilation and a dose of common sense, the melting of materials like ABS, PLA, PET, and nylon do not cause harm to 3D printer users.

But, as plastic is melting in these machines, what exactly is produced by the process?

Timelapse 3D print of a 3D Benchy boat. Clip via Zach Morris on YouTube

Cut out the rumours

In plastics produced from fossil fuel extracts, there is a risk of creating harmful gases when they are melted at temperatures exceeding around 460 – 600°C. The maximum temperature of extrusion in typical desktop 3D printer is between 240 and 250°C.

And so, opening the study, the researchers note that a “3D printers operation temperature is significantly lower than pyrolysis temperature at which CO [carbon monoxide] and HCN [hydrogen cyanide] are formed.”

All samples examined in the SajTom Light Future study are heated up to 240-250°C for this purpose, and vapours emitted from the plastics recorded over a period of 10 minutes.

3D printers are “not a threat”

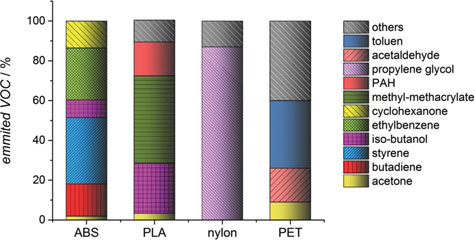

The main volatile organic compounds (VOC) of each 3D printer filament are shown in the table below.

In a 3D printer with print bed dimensions of 400 × 390 × 520 mm, and an air volume of approximately 50%, the total concentration of organic pollutants produced by ABS within an hour reaches about 280 parts per million.

The resulting conclusion then, is that “the concentration of formed organic vapors is not dangerously high” and therefore “not a threat to the user”.

As to be expected, compounds produced by PLA when melted are 32% lower than the levels produced by ABS.

Furthermore the acute toxicity of methyl methacrylate (MMA), the most prominent VOC in PLA, is classified as “low” in an official assessment by the World Health Organization.

Keep the windows open and the filters running

SajTom Light Future was supported in this filament emissions research by 3D printer manufacturer 3DKreator, and the University of Milan, where SajTom Light Future assistant director Dr Tomasz Baran is a postdoctorate student.

The authors recommend that filters, be a critical component of 3D printers which, thankfully, is a commonplace occurrence for the majority of currently available desktop machines.

Seeking to market light-absorbing photocatalytic products, the company also make a case for filters made from their proprietary materials.

In contrast to typical systems, photocatalytic filters are capable of neutralising harmful gases in the air. Such devices have already found use in desktop 3D printers since 2016 and may well find more varied use in future machines.

The next step

Although by no means an exhaustive study, the authors do suggest that further investigation may be explored by changing the experiment’s variables, i.e. filament thickness, machine setting, and room volume.

Development of more eco-friendly 3D printer materials is also at the forefront of many projects around the world, including an initiative funded by the European Union for automotive and aerospace industries.

A full paper of the study discussed in this article can be accessed online in the Journal of Occupational and Environmental Hygiene. It is co-authored by Szymon Wojtyła, Piotr Klama and Tomasz Baran.

To stay up to date with the latest 3D printer materials studies sign up to our newsletter, the most widely read mailing list in the industry, follow 3D Printing Industry on Twitter, and like us on Facebook.

3D Printing Industry is launching a new 3D Printing Jobs service. Register as a candidate or employer here.

Featured image shows: Samples of PLA 3D printer filament. Photo by Beau Jackson for 3D Printing Industry