The European Union has a launched a research project for the creation of 3D printable car and construction feedstock. Monitored by the Italian University of Perugia, the project aims to make biomaterials from food waste or agricultural by-products, and is scheduled for completion in 2020.

Project BARBARA

Project “BARBARA” (Biopolymers with advanced functionalities for building and automotive parts processed through additive manufacturing) focuses on the development of materials specifically for the fused filament fabrication (FFF)/fused deposition modeling (FDM) method of 3D printing with melted plastics. Overall the project has two goals. Firstly, to create 4 new advanced biobased materials. And secondly, to create 3 validated consumer products from these filaments using 3D printing.

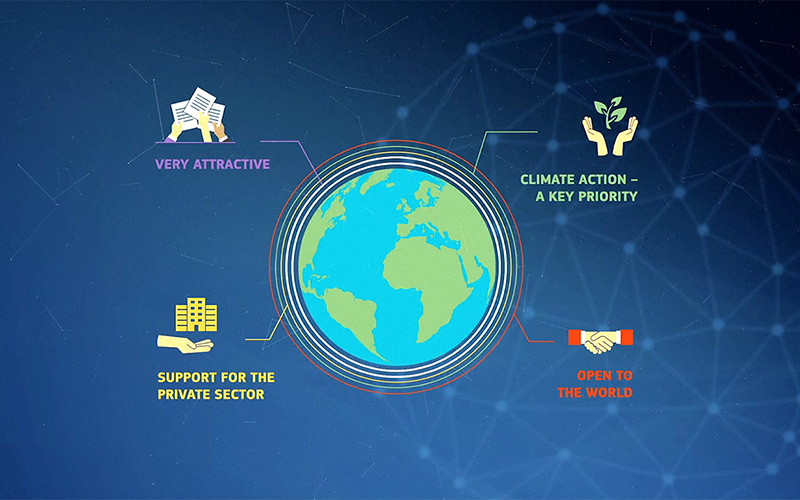

The project is part of the EU’s Horizon 2020 vision to encourage research innovation throughout the continent. Between 2014 and 2020, the initiative is expected to foot almost €80 billion of funding to the vision for “smart, sustainable and inclusive growth and jobs”.

European research excellence

There are 11 institutional and industrial participants collaborating on BARBARA, from Spain, Italy, Germany, Sweden and Belgium. The range of these participants create a sustainable ecosystem reminiscent of the FabCity concept first launched in Barcelona. This system includes food waste suppliers FECOAM and CARGILL; through to raw material development by Celabor, KTH and the University of Alicante; and specialist verification from Italy’s Fiat Research Center (Centro Ricerche FIAT) and Spanish infrastructure and renewable energy management, Acciona Construcción, that collaborated on the 3D printed Alcobendas bridge.

The process and production itself will be conducted by Aitiip, a manufacturing and technology company from Spain that previously worked on project to create a 3D printed motorcycle.

Carbohydrate construction and car production

Materials utilized in the project are selected for their molecular structure – they are abundant and easily degradable polysaccharide/carbohydrates. According to Aitiip, potential product prototypes include “car door handles, dashboard fascia for the automotive sector or moulds for truss joints and structures used in the building sector”.

Materials considered for use are likely to be a kind of biological cement, such as Terra Performa produced by IAAC barcelona, or a filament made from recycled plastic bottles, as used to make adidas Parley sneakers.

To stay up to date with the latest 3D printing material and other news sign up to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Featured image: Future progress graphic from the EU’s Horizon 2020 animated presentation. Image via EU Science & Innovation on YouTube