The British Army has revealed how a desktop 3D printer is aiding its efforts to provide support to the United Nations Mission in South Sudan (UNMISS). Part of Operation Trenton, which was launched this summer, the army is tasked with building a hospital to undertake the care of more than 1,000 UN employees.

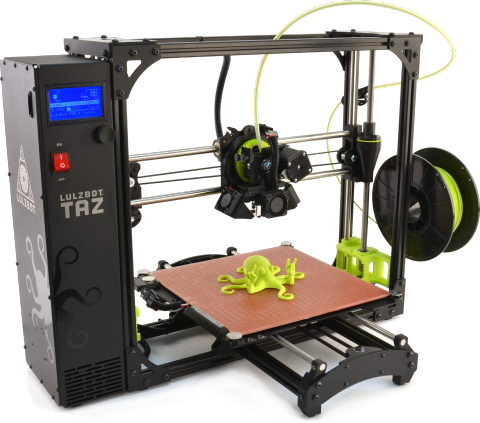

In an official video posted by the force, essential plumbing fixtures needed for this construction are shown 3D printing on a Lulzbot TAZ 6 3D printer. According to an army representative, the components are fulfilling a demand in the project that would otherwise lead to slow, or halted, construction.

The British Army’s first 3D printer in operations

Established in 2011, the objective of UNMISS is “to consolidate peace and security, and help establish conditions for development in the Republic of South Sudan.” Initially, set to last one year, the Security Council has continued to extend the UNMISS mandate, and it is now set for March 2019, after which point it demands opposing parties must end the fight.

In the meantime, around 200 British Army troops from 36 Engineer Regiment have been drafted in for support. This mission, as explained by a Royal Engineer, has been been challenging. “Engineering in South Sudan has faced many problems. A stretched and fragile logistical supply route has resulted in difficulties resourcing components.”

“However,” he adds, “we have resolved some of these issues through use of 3D printer,”

“This is the first time this technology has been used by UK land forces deployed on operations.”

3D printing for plumbings

The Lulzbot TAZ 6 has a build volume of 280 mm x 280 mm x 250 mm

(11.02″ x 11.02″ x 9.80″) making it capable of producing prints “up to the size of football.”

Most of the components produced for Operation Trenton are plumbing parts, including simple brackets, for affixing pipes to walls, and complex junctions, which can channel liquids from three different directions. The turnaround time for these parts is typically less than 12 hours, a dramatic reduction on the weeks it would usually take for a part to be shipped and delivered to the site. In addition, low materials costs and eradicated postage/package, deliver significant cost reductions to the force.

Lulzbot in the military

For the past few years, the U.S. Marine Corps has also been working with a Lulzbot TAZ 6 3D printer as part of Next Generation Logistics initiative.

Satisfied with the results they have achieved so far, the British Army forsees a wealth of opportunity for its further application.

In recent years the technology behind 3D printing has dramatically improved and has yet to be fully explored, there is great potential for the Births Army to use this technology in many different theatres in the future.”

Nominate your 3D Printer and Application of the Year in the 2019 3D Printing Industry Awards now.

For all of the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Join 3D Printing Jobs to find your next opportunity.

Featured image shows plumbing fixtures 3D printed for Operation Trenton. Image via The British Army