The United States Marine Corps have been integrating 3D printing to aid in military operations for the past few years.

From the 1st Marine Logistic Group’s integration of additive manufacturing to create aircrafts, radio brackets, and gas caps, to the development of a biodegradable 3D printed aerial drone delivery system, it is evident that force is investing heavily in the technology.

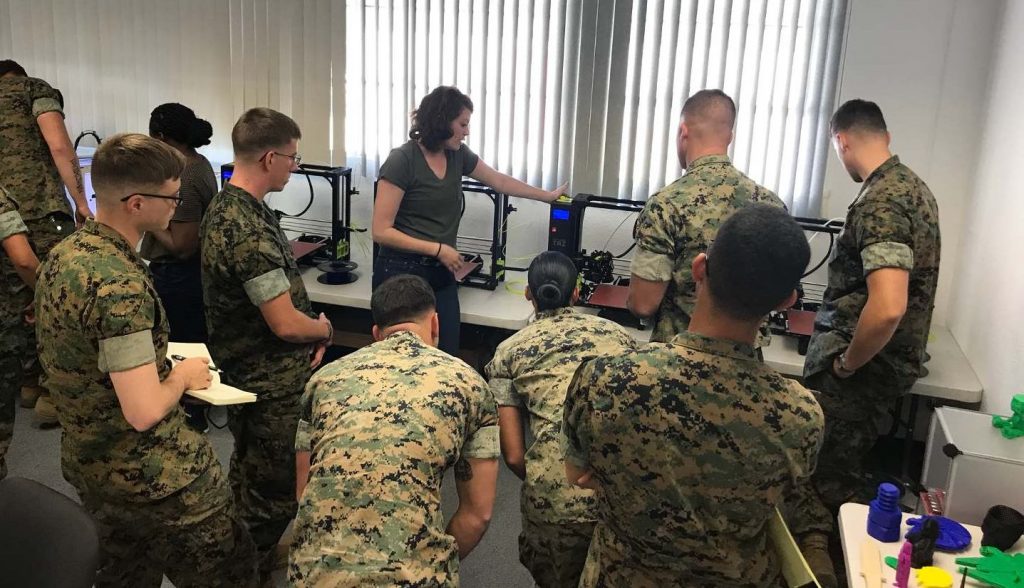

Recently, U.S. Marines have learned to design and create lightweight and accessible equipment for expeditionary environments using the LulzBot TAZ 6 3D printer. This training is part of the Next Generation Logistics (NexLog) initiative and veteran-owned technology and engineering consulting firm, Building Momentum, in Alexandria, Virginia.

Operation 3D print

Established in 2015, NexLog was created to encourage the development of emerging technologies for logistic capabilities within the Marine Corps. In addition to additive manufacturing, the NextLog remit includes both Unmanned Logistics Systems (ULS), and Smart Logistics that covers the development of mobile applications for Marines in tactical environments.

In this particular directive, Lt.Col. Howard Marotto, Deputy Director of NexLog, identified 3D printing as a method that would allow Marines to produce equipment that is no longer available through conventional manufacturers.

“A lot of our older equipment in the Marine Corps, nobody wants to make those items or parts for,” Marotto said,

“..we have to become our own manufacturers on certain low-demand, obsolete type items because the industrial base won’t support us.”

Improvise, Adapt, Overcome

Lost or broken transmission caps and fragile handles from military Humvees (High Mobility Multipurpose Wheeled Vehicle) served as the perfect case study for the Marines’ Lulzbot TAZ 3D printer.

If these parts fail to operate properly, marines cannot transport themselves swiftly to their desired locations.

Using the LulzBot TAZ 6, the team were able to 3D print a more durable humvee handle and transmission cap in under an hour. Typically, the Marines would have had to wait for the part to be delivered, or in some cases, replaced in an expensive refit.

The 7th Marine Regiment, MWSS-372 also recognised the capabilities of 3D printing as their troops redesigned and replaced small plastic parts for Humvee trucks.

Expeditionary 3D solutions

Applying the Lulzbot TAZ 6 to expeditionary missions, the U.S Marines have also been 3D printing in cold conditions.

The team found that clips used to fasten their snowshoes broke easily due to the harsh weather conditions, however, with 3D printing, they were able to design and produce clips that attach to their snowshoes to make sure they no longer fell off their feet during a mission.

The advantages of using a 3D printer have also aided in weaponry as the marines can replace broken rifle handguards and buckles with 3D printed ones. This allows marines to properly secure their weapon to their body as opposed to holding it for long periods of time.

U.S. Marines have described these 3D printed parts as “mission-critical assets” due to its durability accessibility and cost-effective production.

For more stories on the latest developments in 3D Printing subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Want to advance your career in additive manufacturing? Sign up to 3D Printing Jobs here.

Featured image shows Cpl. Christopher Bigham and Col. Farrell J. Sullivan training with Building Momentum to use 3D printers. Photo via LulzBot.