Developed by Creality, the Ender-5 S1 is a midrange FFF 3D printer with an upgraded motion system and a range of premium features. Join us as we review the main benefits of the Ender-5 S1, our experience, testing results, and what to expect from this 3D printer.

Creality is a technology company based in Shenzhen, China, and was established in 2014. It has since developed a large 3D printing portfolio, with the Ender series being its most famous.

The Ender-5 S1 comes well packaged with form-fitting foam sheets to protect the parts. Our 3D printer arrived intact with no damaged or missing components.

Packaging and Unboxing of the Ender-5 S1. Photos by 3D Printing Industry.

Assembly of the 3D printer is easy, as is the set-up, with only a few steps required. It took us about 40 minutes from opening the box to start 3D printing.

Main Benefits of the Ender-5 S1

According to Creality, the Ender-5 S1 has three main selling points that make it a great choice for 3D printing enthusiasts. First, it saves you time by allowing you to 3D print faster with minimal loss in quality, thanks to its upgraded motion system and cooling system. Second, it gives you more creative freedom by enabling you to 3D print a wide range of materials, from flexible to high temperature, due to its upgraded extruder and direct drive system. Third, it makes the 3D printing process easier by providing you with various quality-of-life features and upgrades, such as auto bed leveling, touch screen, runout sensor, and more.

High output at good quality

One of the most noticeable advantages of the Ender-5 S1 is its speed. It has a stable cube frame with extra reinforcement, which reduces vibrations and improves stability. It comes with an upgraded cartesian motion system that allows for higher speeds and accelerations, resulting in shorter 3D printing times while keeping a good level of quality.

The 3D printer also has a powerful 5015 fan and a custom-made cooling duct called the “Urus”, which improves cooling efficiency. This combination is designed to provide uniform airflow enabling consistent quality and accuracy.

Material Compatibility

The Ender-5 S1 can 3D print flexible and high-temperature materials thanks to its direct drive extruder called the “Sprite,” which is reliable for 3D printing materials such as TPU. It also has an all-metal hot end, which can reach up to 300°C. This enables 3D printing of higher-performance materials such as ABS (with optional enclosure), PC, ASA, and HIPS, which need higher temperatures than PLA. The hot end heats up to 200°C in 1 minute and 15 seconds and up to 300°C in 2 minutes 35 seconds.

Extruder assembly. Photos by 3D Printing Industry.

The 3D printer also has a heated bed, reaching up to 100°C. This helps with adhesion and prevents warping. The printbed heats up to 60°C in 3 minutes and 10 seconds and up to 100°C in 9 minutes and 30 seconds.

Included Premium Upgrades and Quality of Life Features

The Ender-5 S1 also has a number of features and upgrades that make the 3D printing experience more convenient and enjoyable. These are usually found in premium 3D printers and are uncommon in this price range.

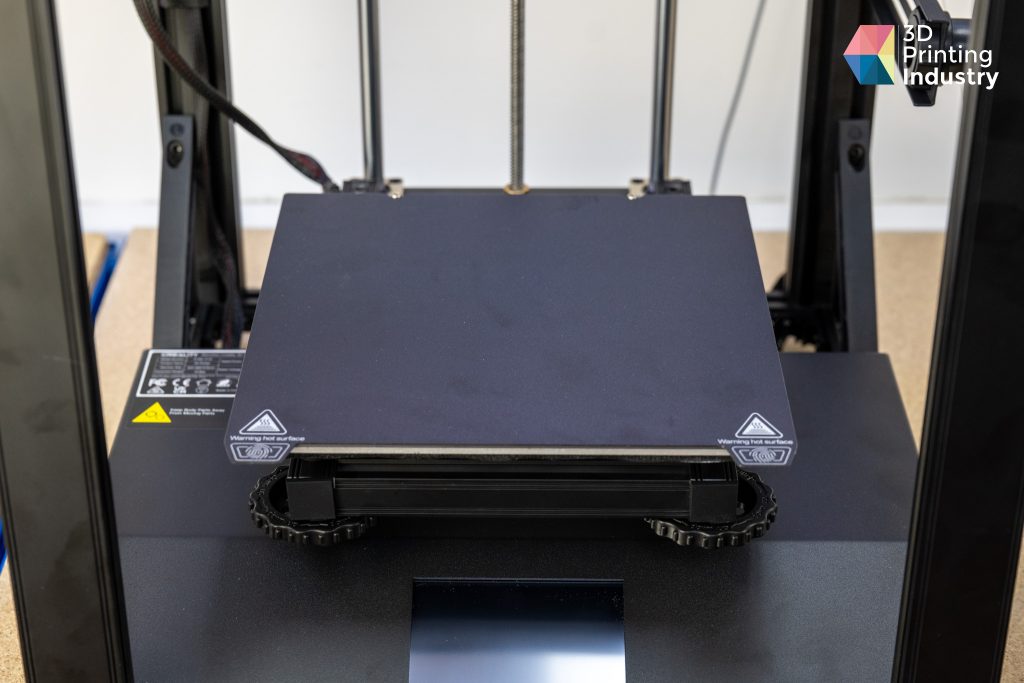

One of them is the textured spring steel PC sheet, which attaches to the magnetic bed. The sheet provides good adhesion for 3D prints but allows easy removal by bending it slightly.

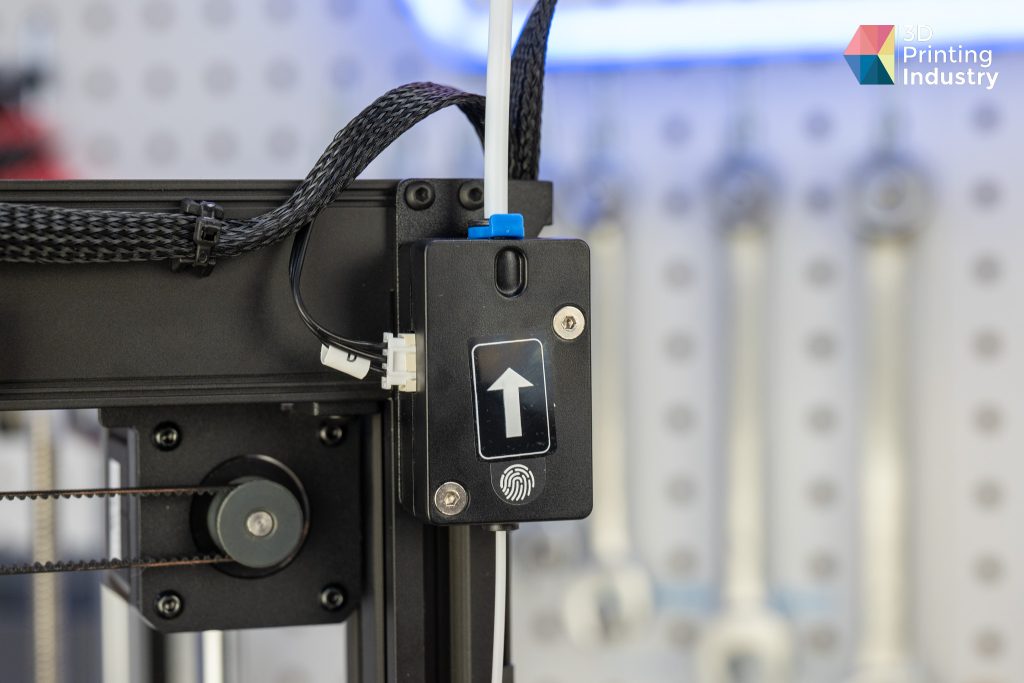

Another quality-of-life feature is the filament runout sensor, which detects when the filament is about to run out. The sensor pauses the 3D print and alerts the user, allowing them to change filament without losing progress, which we have tested. The sensor works as advertised, and the 3D print resumes from where it has stopped.

Print bed and filament runout sensor. Photos by 3D Printing Industry.

The Ender-5 S1 has an auto bed leveling system, which uses a BLTouch probe to measure the distance between the nozzle and the bed at 16 points. The system adjusts for any unevenness or tilt of the bed, ensuring a level surface for 3D printing.

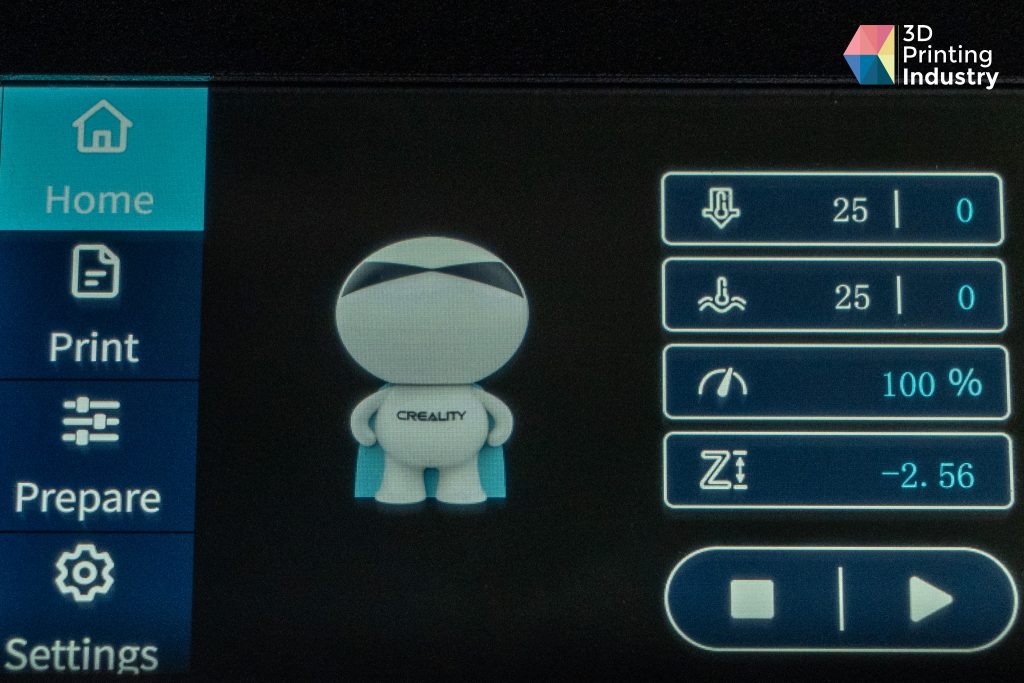

In addition, it has a touch screen with an intuitive UI, which makes it easy to navigate through menus and settings. The screen also allows the user to adjust some parameters mid-print, such as speed, temperature, z-offset, etc.

The Ender-5 S1 comes with its own slicer called Creality Slicer, which is based on Cura. It comes with a range of prepared profiles for the 3D printer, which work well enough. In our testing, we’ve compared both Cura and Creality Slicer, and there wasn’t any noticeable difference in the 3D print quality, but Cura does have more up-to-date settings and features compared to the Creality Slicer.

Benchmarking

At 3D Printing Industry, we test 3D printers comprehensively to determine their strengths and weaknesses. To do this, we collect data on the accuracy of the 3D printer, precision, repeatability, and performance on bridging, overhangs, towers, width, and retraction. After this, we 3D print various models and materials to test typical applications.

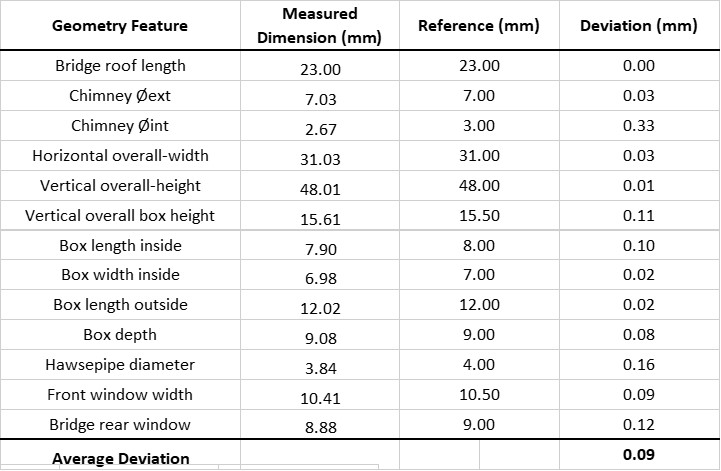

To start, we 3D print a Benchy to measure and compare the dimensions of various features such as the chimney, cargo box, and front window to the original model to test the accuracy of the machine. The average dimension deviation between the reference and the 3D printed model is 0.09mm, which is a very good result, as the average for most other 3D printers for this test is 0.15mm.

3D printed Benchy and a table of dimensional measurements of the 3D print. Photo and table by 3D Printing Industry.

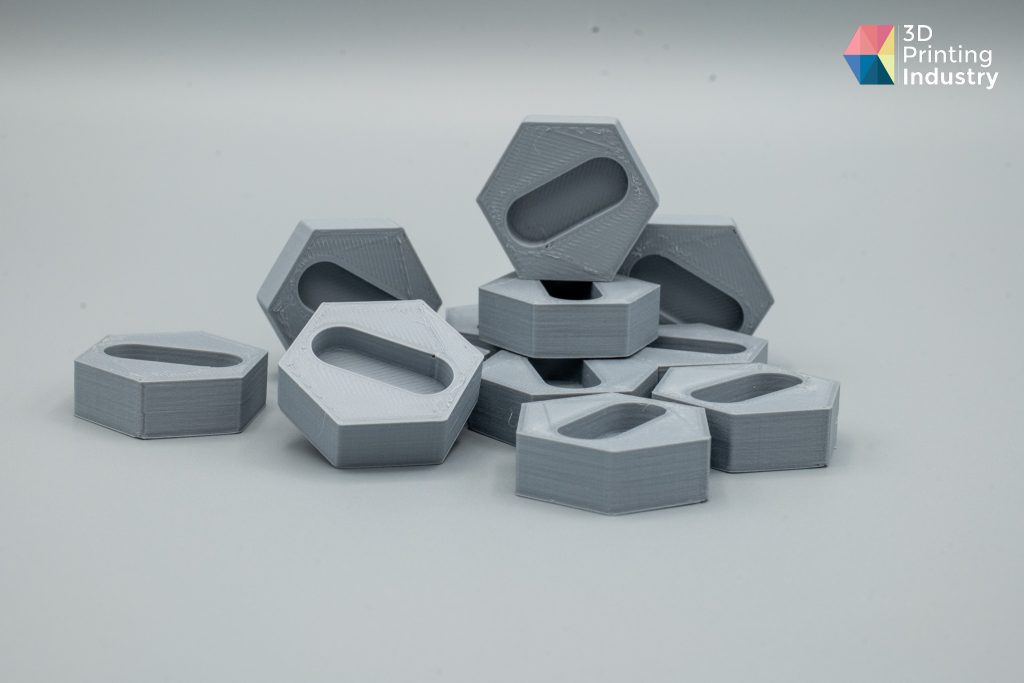

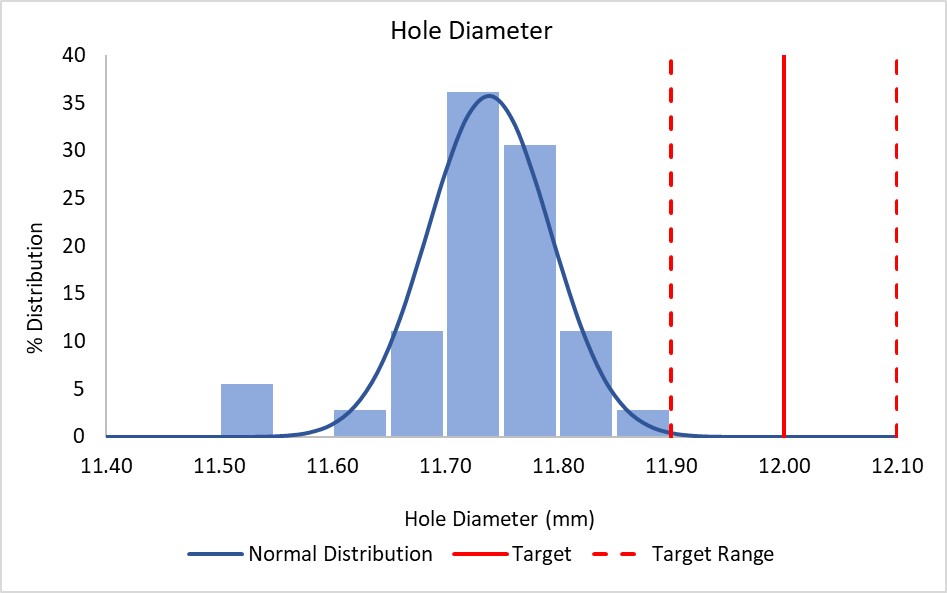

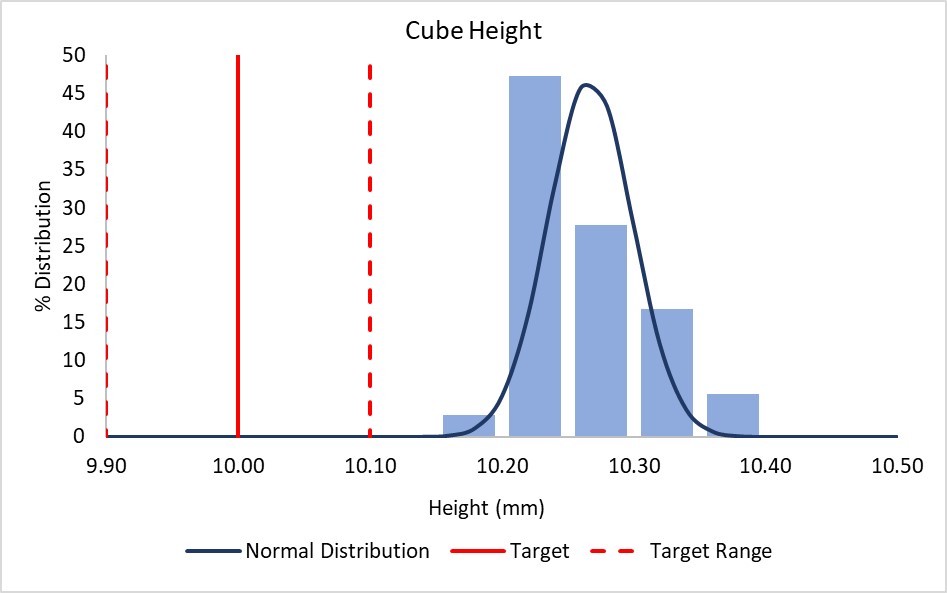

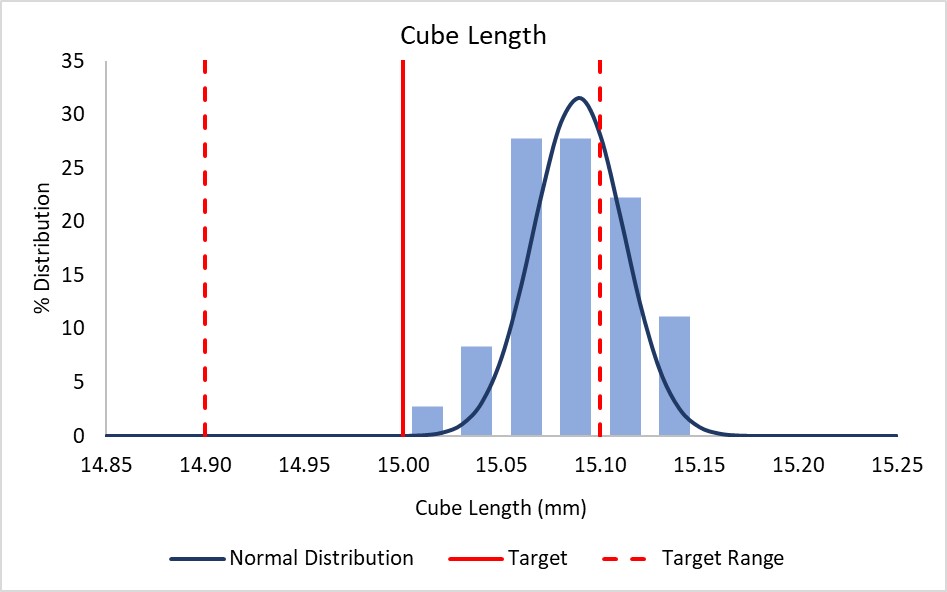

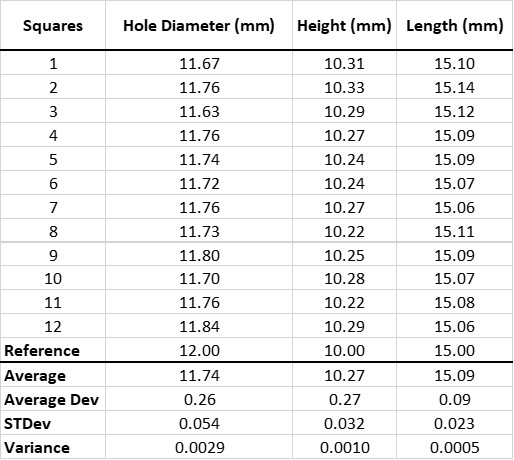

We then conducted a series of repeatability tests for three different parts (Square, hexagon, and tube shapes), which were 3D printed 12 times, measured, and compared to the original part dimensions. For a successful result, the measured dimensions should have an average deviation of less than 0.1mm and a standard deviation of under 0.05mm.

Repeatability tests. Photos by 3D Printing Industry.

In this series of tests, dimensional accuracy was lower than the target of 0.1mm, with the average deviation coming in at 0.15mm, but it was fairly consistent, with the average standard deviation being 0.03mm. This would imply that the 3D printer is over-extruding, and to achieve dimensional accuracy, one would have to tune settings such as Flow Rate and Hole Horizontal Expansion in the slicer. If one is not looking for perfect dimensional accuracy without tuning, the Ender-5 S1 3D prints quite well out of the box.

Histogram graphs and cube measurements table. Images by 3D Printing Industry.

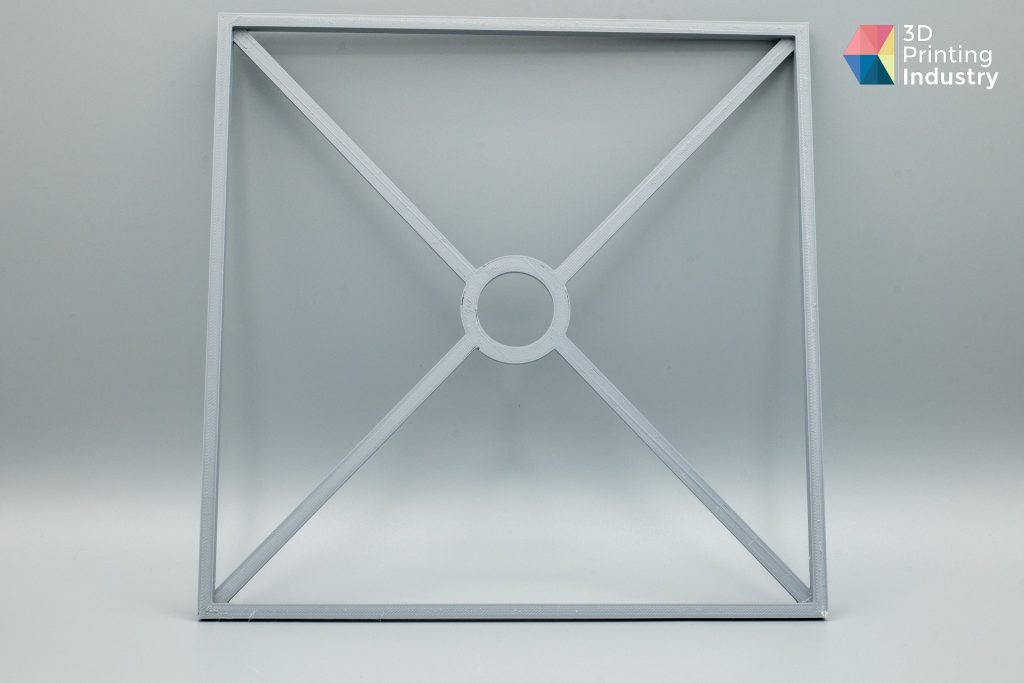

Following this, we 3D printed a tower and a bed width test to determine the maximum 3D print dimensions, as they don’t always match up to what is stated by the manufacturer. Our results show that the actual 3D print dimensions are quite close to what is advertised, with the usable height being 279mm out of 280mm and the width being 218x218mm out of 220x220mm. We noticed that in the tower test, the top third of the tower gets progressively worse as it gets higher. This seems to be due to the wobble of the cantilevered build plate, which is only supported on one side; as such, users should be mindful of this when 3D printing tall models with small bases.

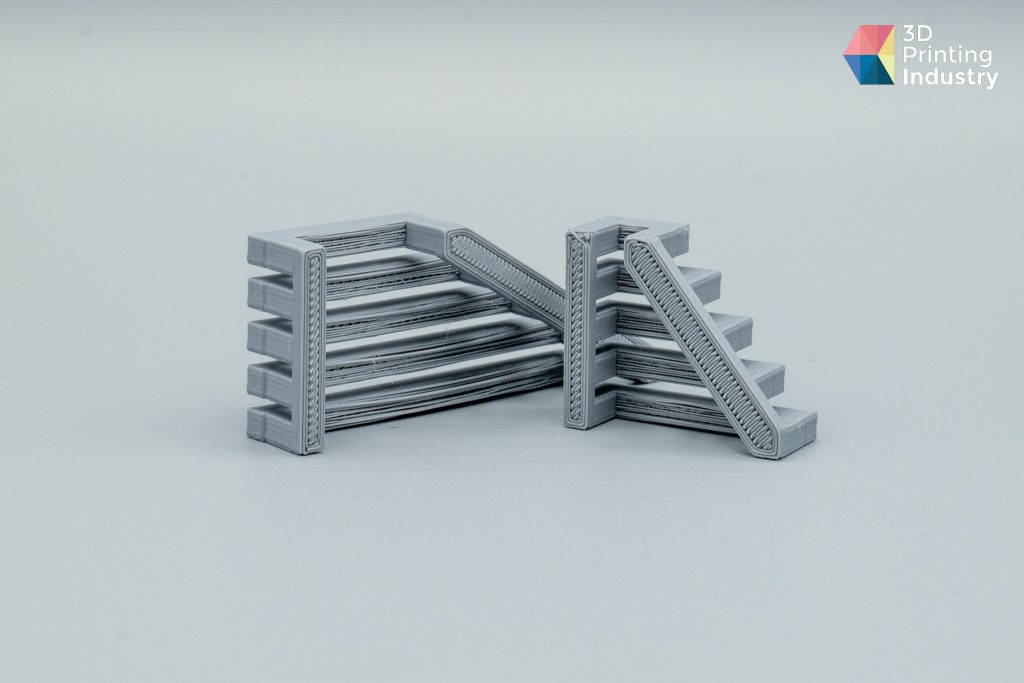

Bridge, overhang, tower, width, and stringing tests. Photos by 3D Printing Industry.

Next, we tested how well the Ender-5 S1 handles bridges and overhangs. We 3D print these in both the X and Y axis to see if there is any discrepancy. The bridging test 3D printed well, maintaining good quality up to 25 mm in both X and Y; this is quite good as the average is usually around 15mm. The 3D printer performed quite well for the overhang test 3D printed in the X-axis going up to 60°, but the Y-axis one only managed to maintain good quality up to 55°. This performance is slightly above average, which is 55° for other 3D printers.

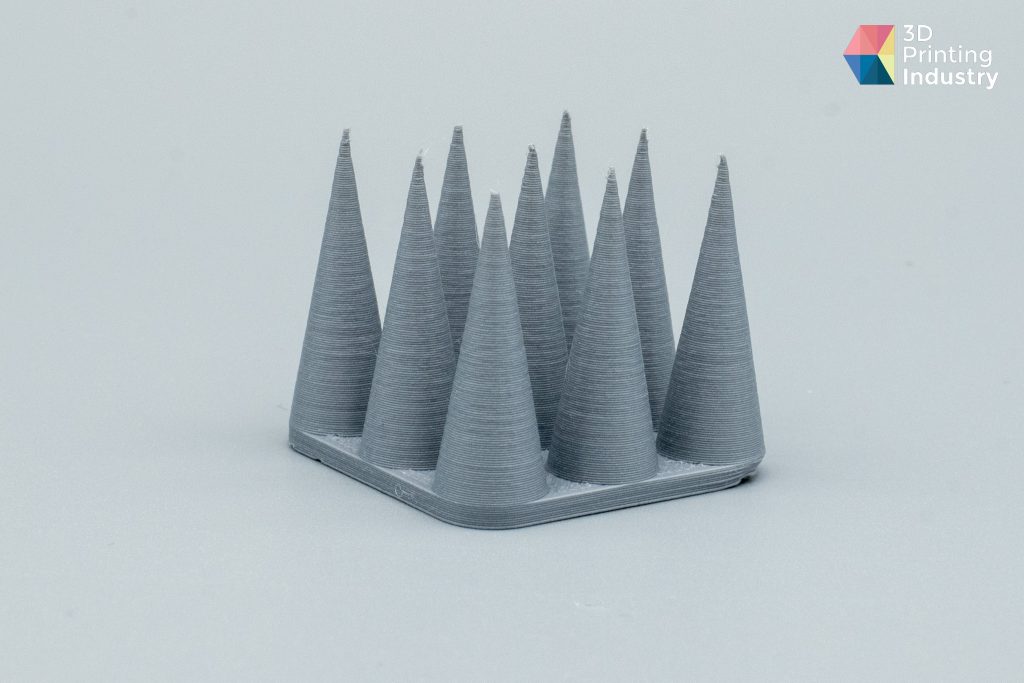

The 3D printer performed very well on the stringing test, giving us a very clean 3D print. This is due to its high-quality direct drive system and cooling. This test shows that the Ender-5 S1 handles retraction very well.

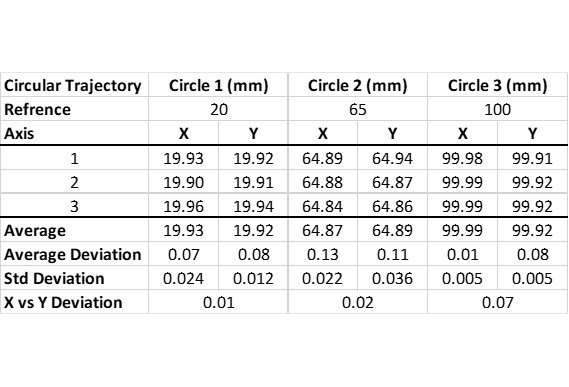

We’ve also tested circular trajectory to see how good of a circle this 3D printer can produce. It is common for 3D printers to be off in one axis, making circles closer to an oval. In this case, the Ender-5 S1 performed great, with all three 3D prints having consistent measurements in both X and Y axes with the deviation below 0.1mm.

Circular trajectory 3D prints and data table. Photos and table by 3D Printing Industry.

To test fine tolerances and accuracy of the 3D printer, we 3D print a set of nuts and bolts and a planetary gear. Both of these 3D prints require very good 3D print accuracy to move freely after being 3D printed.

Small precision test and planetary gear. Photos by 3D Printing Industry.

The Ender-5 S1 did not disappoint us and has produced the nuts and bolts and the planetary gear that move smoothly without problems and no post-processing, indicating good 3D print accuracy.

Speed tests

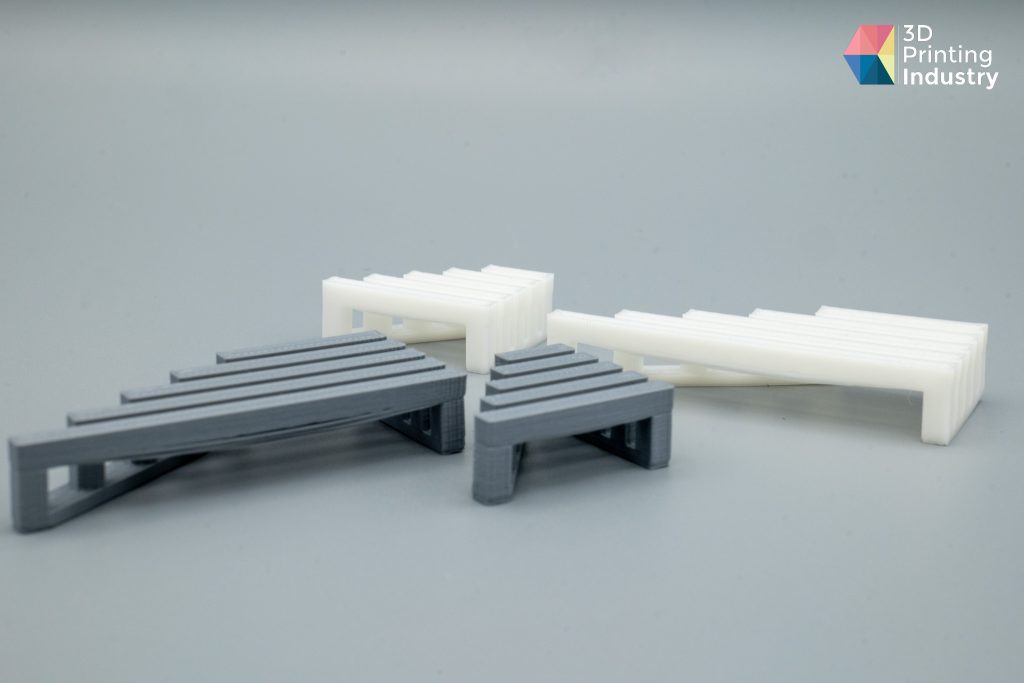

We 3D printed a series of models to test the impact of 3D printing speed on quality and time. We used the Benchy as our model, which has various geometric features that challenge any 3D printer. This also allowed us to compare the speed-quality trade-off.

Speed tests. Photos by 3D Printing Industry.

We started with a slow speed as a baseline which is equivalent to a standard FFF 3D printer, which took 70 minutes to complete. Then we increased the acceleration to 2000mm/s2, which is the advertised limit of the Ender-5 S1. This reduced the 3D print time by almost 30% to 50 minutes without compromising quality.

Next, we increased the 3D printing speed to 120mm/s while keeping acceleration constant. This further reduced 3D print time but at the expense of quality. We noticed cooling issues with overhangs and under-extrusion in some areas. The fastest Benchy we 3D printed took 40 minutes but had poor quality. This may be acceptable for some users, but they should know this trade-off between speed and quality before buying.

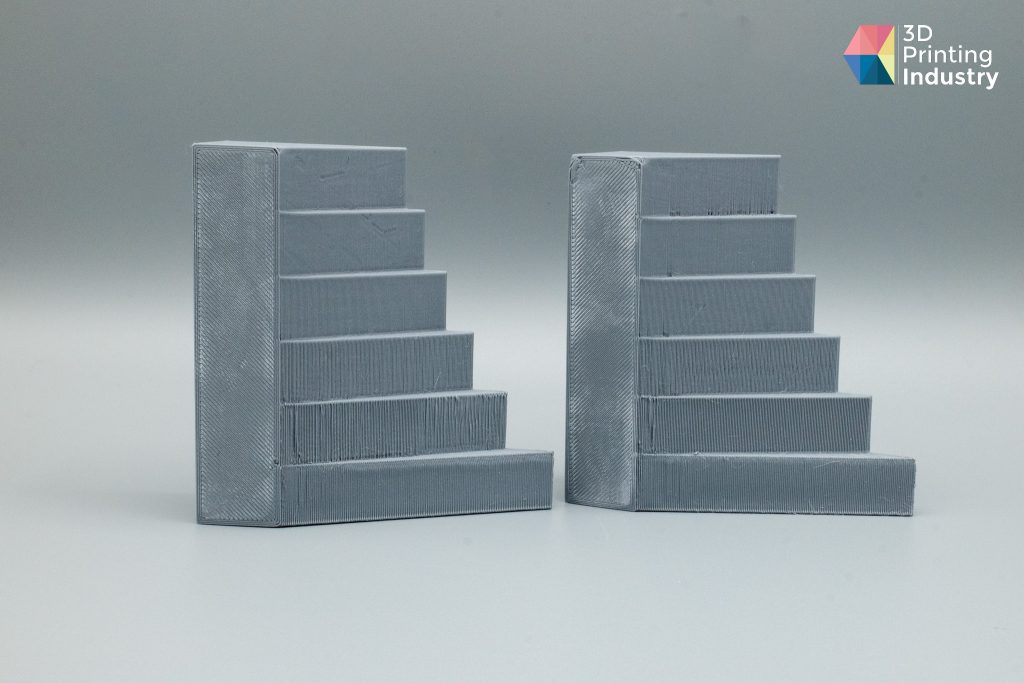

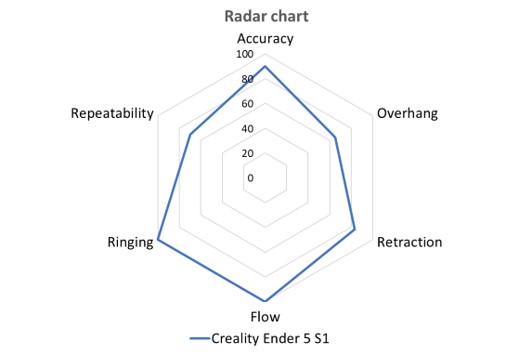

3DPI Benchmark

We also 3D printed the 3D Printing Industry’s own benchmark model, which combines many of our smaller tests into one part. We used this model to evaluate the performance of the Ender-5 S1 based on our criteria.

3DPI benchmark in PLA and radar chart. Photos and charts by 3D Printing Industry.

The Ender-5 S1 performed very well on this benchmark, except for the overhang tests. We observed consistent failures of the overhangs that went from 45° to 60° on this particular model, as they curled up and got caught by the nozzle. This resulted in them being ripped off the rest of the 3D print.

In other areas, the Ender-5 S1 performed very well. It has successfully 3D printed very thin walls in both X and Y. In the tolerance test, we could take out all the cylinders up to 0.2mm, which is an impressive result. There is no visible ghosting present on the 3D print, which one might expect when 3D printing at high speeds. There is minimal stringing showing that retraction works quite well on this 3D printer.

Overall, the Ender-5 S1 scored 84/100, which is excellent. A good quality 3D printer usually has a score of 60+.

Applications and material tests

Finally, we 3D printed a selection of models using different materials to see how the 3D printer would handle them in various use-case situations with a range of materials.

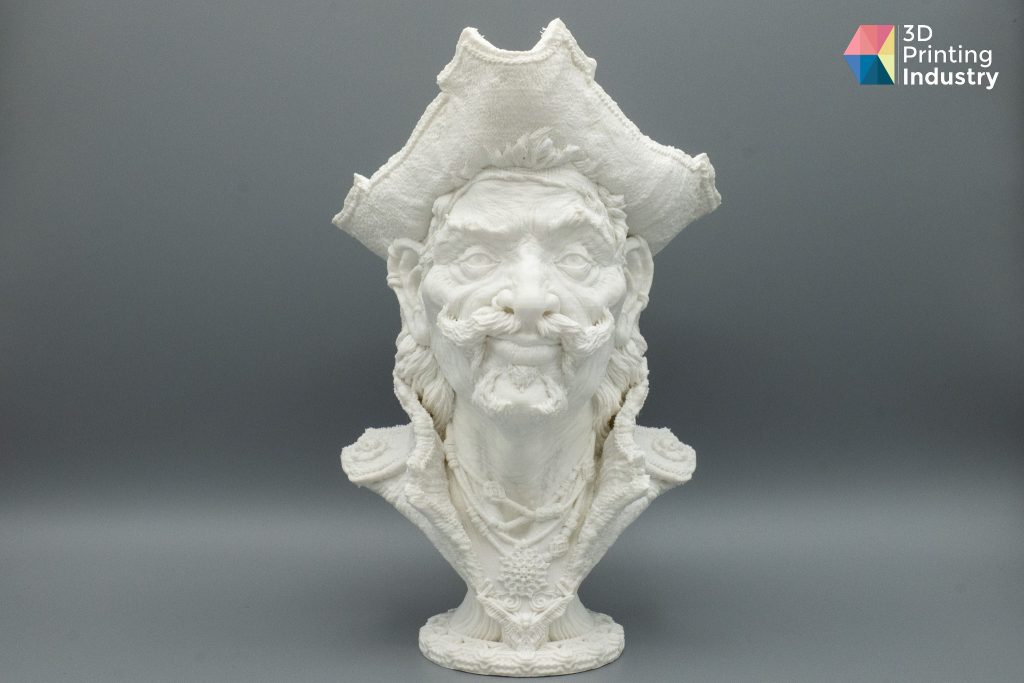

PLA

We chose the Salty McCreedy bust by Ben Dansie to test how the 3D printer will handle a large, detailed 3D print that would take over 48 hours to complete. The model has a lot of texture, does not require supports, and was scaled to 220 mm in height.

Salty McCreedy in PLA. Photos by 3D Printing Industry.

The bust came out great. The Ender-5 S1 completed this long 3D print without failures or any major defects. This demonstrates how dependable this machine is on longer-running 3D prints, making it a great choice for hobbyists and prop makers.

TPU

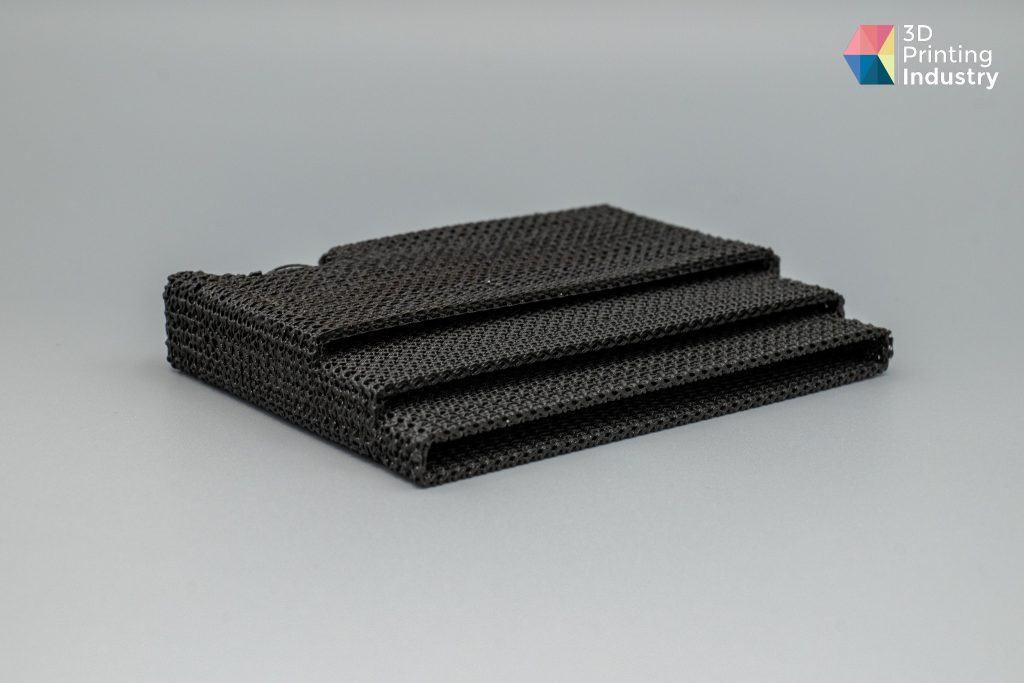

Next, We challenged the 3D printer with a TPU 3D print; we chose a card wallet that 3D prints upright with gyroid infill to really challenge the Ender-5 S1. Flexible filaments are tricky to 3D print and give most users a lot of trouble, so we wanted to see if Creality’s “Sprite” extruder could handle it.

TPU wallet. Photos by 3D Printing Industry.

The wallet was 3D printed successfully. It stuck to the build plate a little too well, leaving some of the first layer on it, but other than that, there were no defects or layer shifts. Adhesion between layers is also very strong, making this part entirely functional. We consider the Ender-5 S1 to be capable of 3D printing flexible filaments with ease.

Polycarbonate / PC

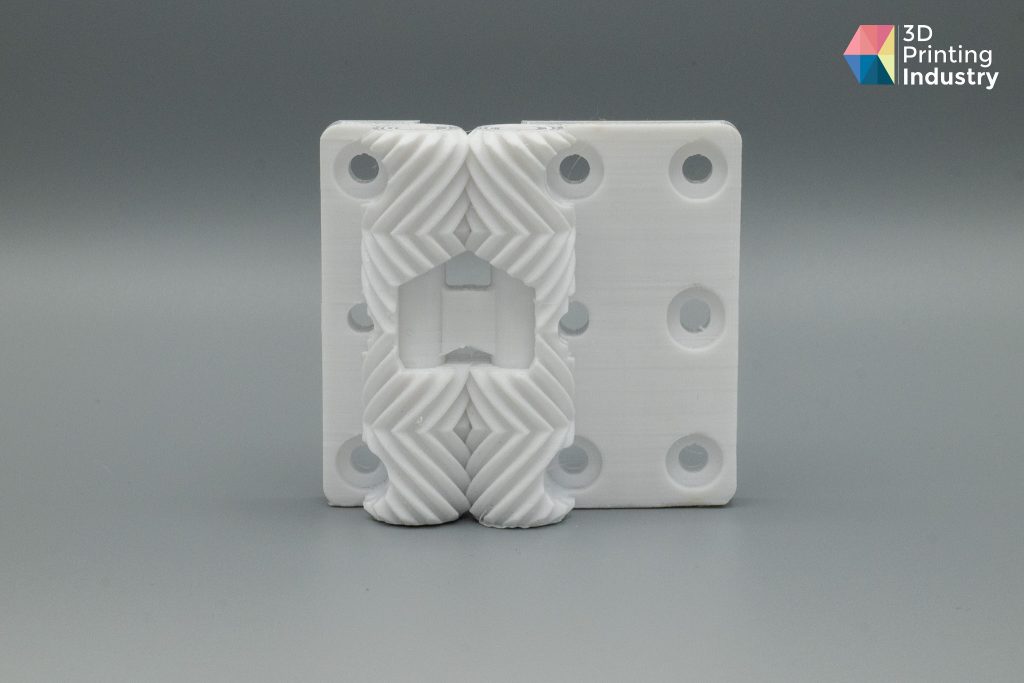

We then used the Ender-5 S1’s all-metal hot end to 3D print a functional part out of Polycarbonate, a material that requires higher temperatures to 3D print. The all-metal hot end allows users to 3D print with higher temperature filaments, more suited to engineering and prototyping uses. For this test, we chose a geared hinge that requires fine tolerances and high strength. If the 3D printer is inaccurate, the part can easily fuse or be very stiff when moving.

Polycarbonate print in place gear hinge. Photos by 3D Printing Industry.

The gear hinge 3D printed very well and moved freely after 3D printing with little to no wobble. We had to use a brim and still had some minor warping at the bottom, but nothing that affected the mechanism. This shows that the 3D printer can handle high-temperature, high-strength materials suitable for mechanical parts and prototyping.

PETG

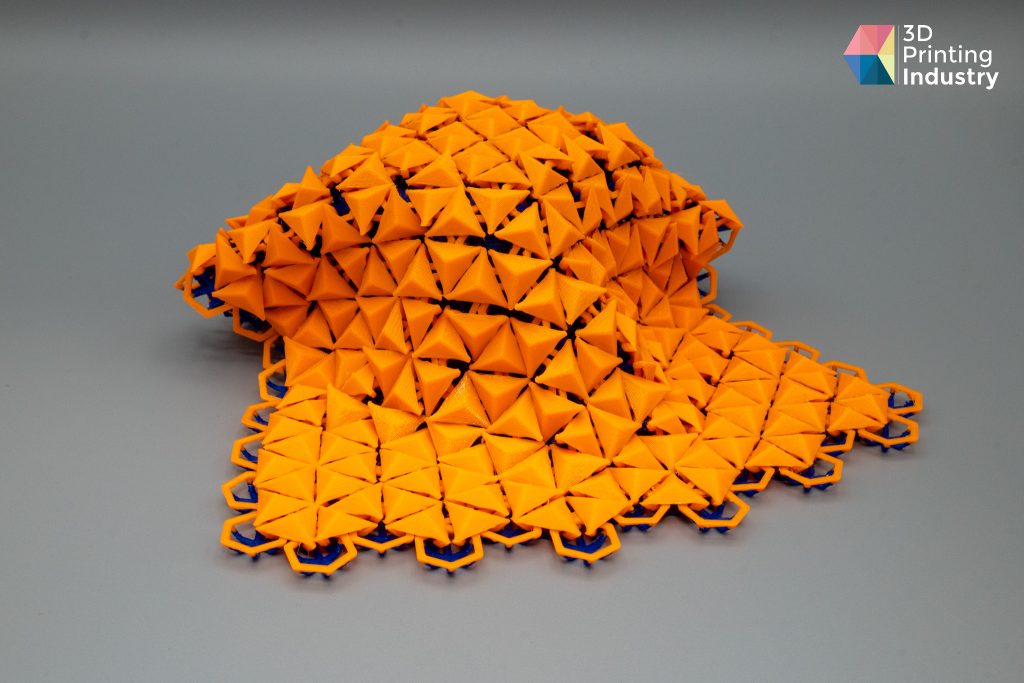

We also 3D printed a large piece of tetrahedron chain mail with PETG, a popular alternative to PLA. This was a good test for the 3D printer’s retraction and cooling abilities, as PETG 3D prints at a higher temperature, and the model has many small bridges. The parts were also thin and needed a stronger material than PLA to be functional. PETG is notorious for stringing as well, so this test will showcase the retraction capabilities of the Ender-5 S1.

PETG Tetrahedron mail. Photos by 3D Printing Industry.

This 3D print was challenging, as it required a perfectly flat bed surface, which is hard to achieve for most 3D printers. We had to use a raft to 3D print it successfully, but the final result was very good. We also tested the filament runout sensor on this 3D print, swapping to another color filament mid-way. The Ender-5 S1 performed this easily; the 3D printer paused, saved the progress, and allowed us to replace filament and resume the 3D print smoothly; impressive on a complex 3D print with so many individual parts.

Our Experience

Our experience with the Ender-5 S1 is mostly positive, but a few areas could be improved.

The packaging of the 3D printer is sturdy, and the parts are well-protected with form-fitting foam sheets. The 3D printer arrived in good condition, with no visible damage or missing parts.

The 3D printer is easy to assemble and set up, requiring only a few steps. It comes in three pre-assembled pieces with clear instructions and tools. The wiring is also simple and labeled. The whole process took us about 40 minutes.

The machine is ready to 3D print after the initial setup. The touchscreen is handy for starting and controlling the 3D printer, but it beeps loudly every time it is touched, and there is no option to turn it off.

A strange quirk that we noticed is that the bed and nozzle heat up separately when starting a 3D print, which takes about 5 minutes to reach 60°C and 200°C. However, if we use the preheating option before starting a 3D print, they heat up together and reach the target temperature in 3 minutes.

After the first few 3D prints, the POM wheels started to show signs of wear which progressed very quickly. While this didn’t impact our 3D printing, the problem persisted even after adjusting them following instructions.

The PC textured spring steel sheet provides very good first-layer adhesion and has convenient grooves to help align it with the print bed. However, the PC surface is easy to damage when removing some 3D prints and when 3D printing at high temperatures such as 250°C+ for the hot end and 70°C+ for the print bed.

The Ender-5 S1 works quite well out of the box. It has the potential to perform even better which can be unlocked by experienced users through further tweaking and fine-tuning.

Final Verdict

The Ender-5 S1 is a fast and versatile 3D printer that offers a range of premium features and upgrades for a reasonable price. It is suitable for beginner and intermediate users who are looking for improved performance and quality-of-life features without needing to do any modifications themselves.

However, the 3D printer is not perfect and has some drawbacks and limitations. While it can 3D print as fast as advertised and offer significant time savings, there will always be some loss of quality as the speed goes up, which we believe is a trade-off any interested buyer should be aware of.

We recommend the Ender-5 S1 to users who value speed, convenience, and reliability as it 3D prints very well out of the box. Users who are looking to achieve the best quality and accuracy should be prepared to spend some time and effort on tuning and optimizing the machine, but this is definitely possible on the Ender-5 S1.

Specs

| Printing Technology | FFF/FDM |

| Build Volume | 220*220*280mm |

| Product Dimensions | 425*460*570mm |

| Package Dimensions | 578*474*340mm |

| Net Weight | 12.2kg |

| Gross Weight | 14.7kg |

| Extruder Type | “Sprite” dual-gear |

| Extruder Material | Direct Drive Extruder |

| Leveling Mode | CR Touch |

| Mainboard | 32-bit silent board |

| Max. Printing Speed | ≤250mm/s |

| Typical Printing Speed | <120mm/s |

| Acceleration | 2000mm/s2 |

| Nozzle Type | Brass nozzle XL |

| Nozzle Diameter | Standard 0.4mm |

| Printing Accuracy | ±01mm |

| Layer Height | 0.05-0.35mm |

| Filament Diameter | 1.75mm |

| Nozzle Temperature | <300°C |

| Heated Temperature | <110°C |

| Build Surface | PC spring steel sheet |

| Power Loss Recovery | Filament Runout Sensor |

| Rated Voltage | 100-120V~.200-240V~50/60Hz |

| Rated Power | 350W |

| File Transfer | SD card. USB Type-C cable |

| File Formats | STL, OBJ |

| Supported Filaments | PLA. PETG. ABS. TPU, PC. ASA. HIPS |

| Slicing Software | Creality Slicer. Creality Print, Cura. Repetier-Host. Simplify3D |

| Ul Languages | English, Spanish, German, French, Russian, Portuguese, Italian, Turkish, and Chinese |

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Creality Ender-5 S1. Photo by 3D Printing Industry.