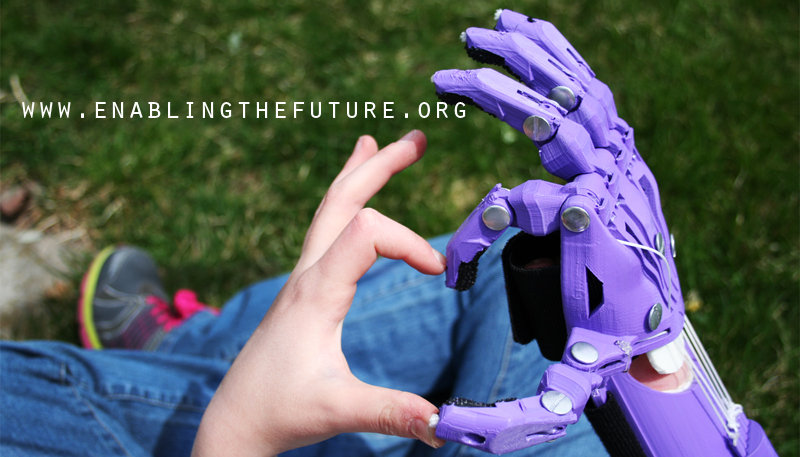

At the end of last month, exciting news was reported that the most notable creator of low-cost 3D printed prosthetics, e-NABLE, had received a $600,000 grant from Google.org. Today, the Enable Community Foundation (ECF) laid out a highly detailed two-year plan outlining exactly how they’d use that money, including the hiring of new staff, the developing of new Handomatic software, and getting 6,000 3D printed prosthetics out to those in need over the next two years.

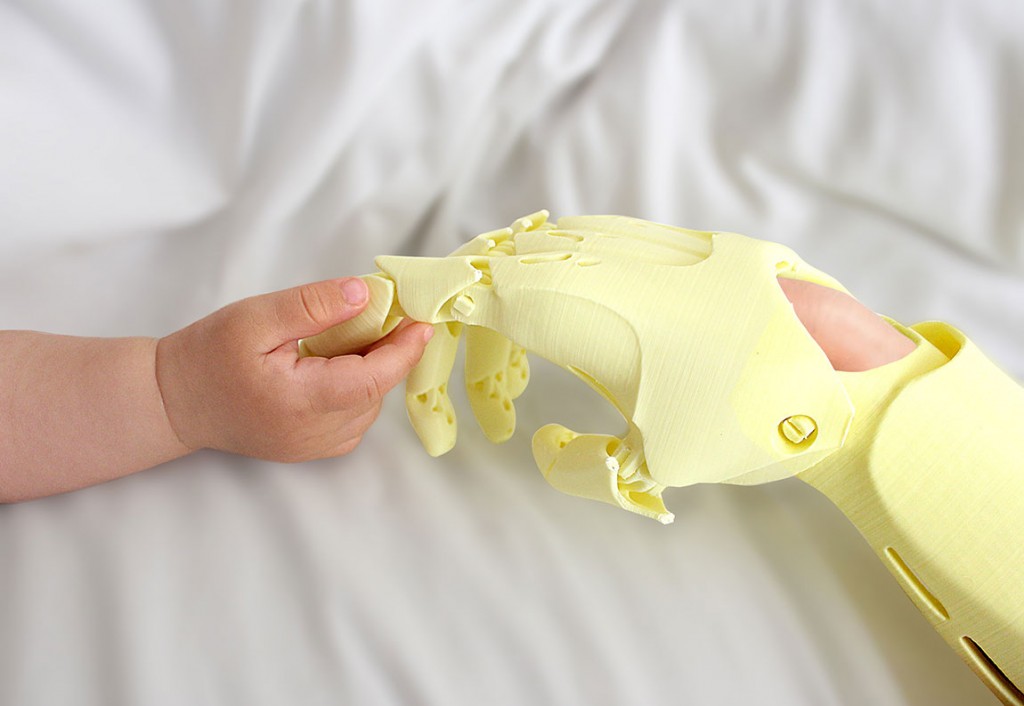

e-NABLE has demonstrated just how effective a distributed 3D printing network can take advantage of open source design to make the world a better place. With their funding from Google, ECF plans to make this network tighter, smoother, and better through a variety of measures ranging from a database for aggregating information about hand designs to improving the designs themselves. So, while e-NABLE hires on new staff to aid their volunteers in designing and manufacturing prosthetics, the group will also be collecting data on how happy wearers are with their new devices, as well as how easy they were to be printed and assembled by 3D printing volunteers. This will help inform future iterations of their prosthetics, which will be better organized with standardized language across the web.

The organization also seeks to expand their device portfolio from wrist-powered hands for those with amniotic band syndrome to exoskeletons, orthotics, and arm prosthetics. To design these new devices, ECF plans to launch global design competitions with cash prizes through such sites as GrabCAD, with their first contest likely to take place this fall. And e-NABLE will bring these 3D printed prosthetics abroad by partnering with international aid organizations, also starting in the fall. Not only that, but ECF plans to connect with commercial medical device manufacturers in order to get their prosthetics out of their own community and into the industrial world, as well. They’re also seeking to partner with universities, introducing fellowship programs, and with companies like 3D Hubs, for the possibility of producing devices through their 18,000+ network of 3D printer owners.

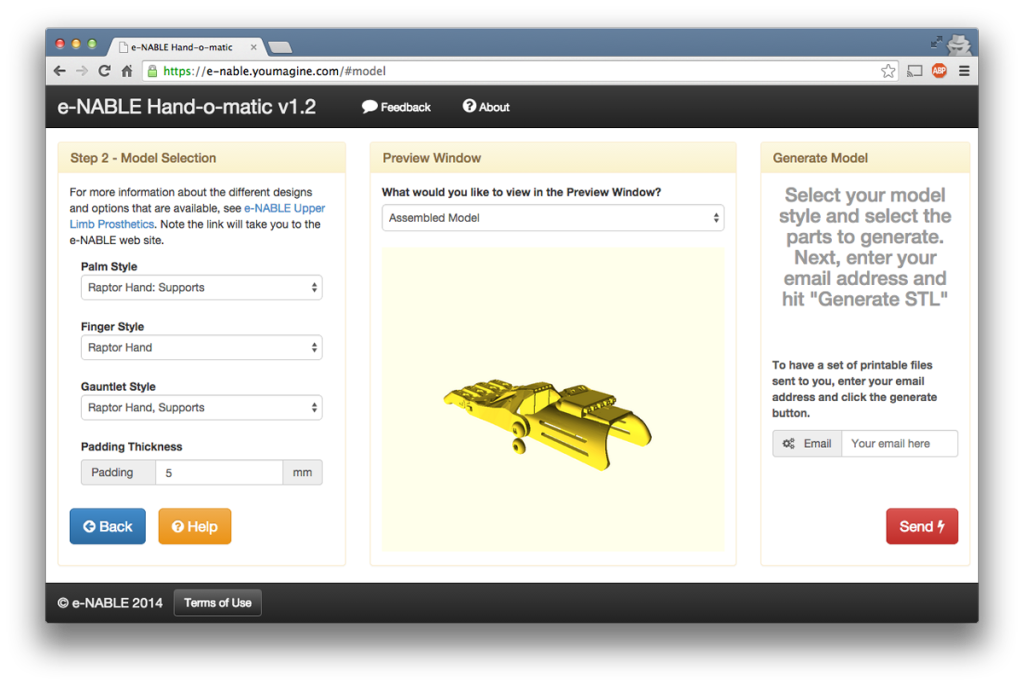

Another significant plan is an upgrade to their Handomatic app, a parametric software that allows anyone to tailor a prosthetic hand to a specific wearer to 3D print it themselves. Handomatic 2.0 will be even more effective at creating customizable devices and, with the Handomatic 2.0 Mobile app, practitioners could potentially scan a person’s arm to fabricate a personally-tailored device while in the field. And, because e-NABLE plans to make their hands easier to print and assemble, the Handomatic app will be even more useful.

All of these improvements will help the non-profit meet its goal of getting 6,000 3D printed devices to people in need over the course of the next to years, as well as engage 10,000 3D printer users to fabricate their designs, reduce the material cost of their prosthetics from $45 to $25, and reduce the time it takes to get their devices to their wearers by 60%. Given the detailed outline posted on the e-NABLE site, I’d say that ECF really knows what they’re doing and has the means to make these goals. Maybe by 2020, there won’t be a person in need of a prosthetic that can’t get one.