UK 3DP company Design Reality just released a quick video following a rapidly prototyped pair of safety goggles from the design stage, to being 3D printed on an Objet500 Connex3 and to being tested in the field.

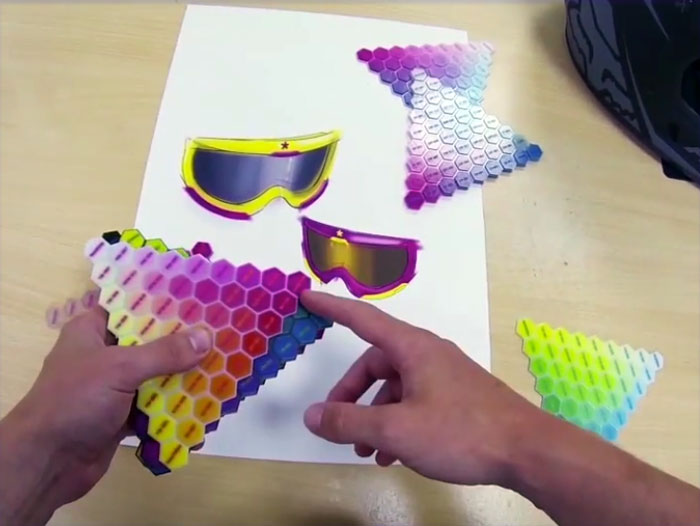

The first step for the goggles is a concept drawing that dictates general shape and color before being turned into a three dimensional CAD drawing. The CAD drawing would then be converted into a 3D printable file and since the goggles are being printed on a Connex3, the colors and build materials are then programmed into the printer.

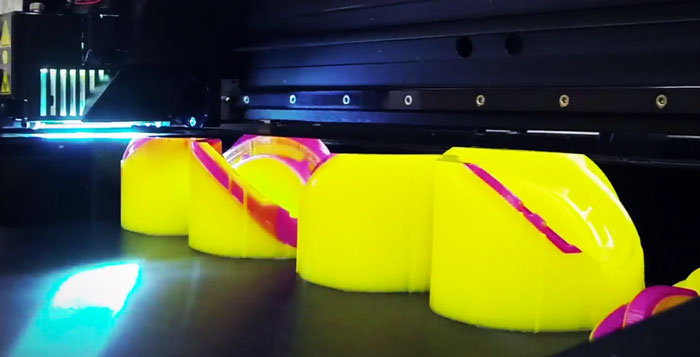

The Connex3 has eight independent print heads which will allow you to print in multiple materials and multiple colors at the same time. The individual colors are chosen from the 46 available shades or the hundreds of blended hues and the removeable support structure is added. In this case a water soluble gel-like material that will be easily removed and washed away with a high power water jet.

Once the frame of the goggles has been printed and cleaned, it is quickly finished by adding a laser cut visor, a flexible strap and foam lining on the inside so they are comfortable to wear. Once completed, the Design Reality team heads off into the field for some real world testing. In this case mountain biking with a GoPro camera so we can see all the exciting action.

Remember, this took place over a period of only three days. Take a look at the video here: