3D printing has already become a driving force in medicine and now it is set to go up a gear with a purpose-built clinical center in Chongqing Fengdu.

An initial investment of $7.5 million will get this center of excellence up and running, although that doesn’t go as far as it used to. More money might be required if the center is going to live up to its promise of providing implants within 24 hours. It also wants to form a bioprinting research hub that can form a base for the burgeoning 3D printing scene in China.

The center will focus on producing tailor-made implants, as well as medical models that will help surgeons plan their procedures more effectively.

3D printing taking over the implant world

Implants have come a long way in recent years and now 3D printing is becoming the preferred choice for the likes of hip replacements, jaw implants and more.

Additive manufacturing is perfectly suited to this kind of work as each implant can be tailored to the patient with the help of CT scanning and computer modelling. Every implant is effectively a one-off, so 3D printing is a much faster and more effective way to work.

These are exciting times in the industry, too, and material science is coming under close scrutiny. Right now the medical world is sticking with titanium, but that is likely to change in the coming years. Researchers are working on ceramic that can mimic bone and others are actually looking to recreate the structure of bone with metallic nanomaterials.

Bioprinting is really on the way

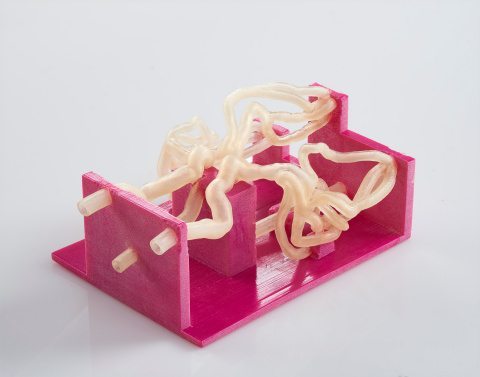

Further down the line we’re looking at genuine bioprinting, or at the very least making scaffolds that will encourage regrowth of bone and cartilage to form a natural repair.

Bioglass, which has been with us since the 60s, but now a number of institutions are using 3D printing to turn this flexible substance into replacement spinal discs and cartilage for our knees.

We are also steadily homing in on viable transplant organs, although deep vascularized body tissue is still posing problems to the 3D printing community. This center and more like it around the world could help tackle these problems and take additive manufacturing to the next level.

Models can help surgeons around the world

Medical models, meanwhile, have revolutionized surgery and helped doctors around the world to reduce their time in surgery. This has streamlined the whole process as doctors can plan their procedures in advance, carry out less invasive operations because they know exactly where to cut and what they need to do in advance and get out of surgery faster.

That means they can treat more patients and each procedure becomes faster, cheaper and less dangerous. The initial expense of a medical model pales into insignificance when you factor in the time it saves and the sheer dollar value you can attach to that.

Models have also proved invaluable when training doctors to deal with rare problems or even to visualise simple systems. Trainee surgeons will still work with cadavers, but they can access the models at any time and truly understand how some of the rarer conditions can manifest themselves in the human body without simply looking at books and pictures.

Educational models are vital for trainees

A visual representation of a condition or specific injury can help prepare doctors, so when they come face to face with them in the real world then they are better prepared. That will save lives down the line.

3D printing centers like this can only be a good thing and it’s good to see that China, a global superpower and the home of mass manufacturing, is starting to truly embrace 3D printing. The Far Eastern nation has already accomplished great things in construction and now we can expect to see China driving progress in the medical world.

These are exciting times, so let’s wait and see what China has to offer. We’re pretty sure it is going to be spectacular.