Glass 3D printing holds a great deal of potential, not just for creating intricate home decor and lighting solutions or even to manufacture bespoke specs, though those are certainly on the table. 3D printing glass could render new methods for making fiber optic cables that are exponentially more efficient at transmitting light, and, therefore, data. And, while extruder manufacturer Micron3DP has been experimenting with the technology, Neri Oxman’s Mediated Matter Group at MIT has just unveiled a fully-fledged glass printing platform, dubbed G3DP, according to architecture site ArchDaily.

In collaboration with the university’s Glass Lab and Department of Mechanical Engineering, G3DP is a highly precise method for 3D printing optically transparent glass. Prof. Oxman explains to ArchDaily, “G3DP is an additive manufacturing platform designed to print optically transparent glass. The tunability enabled by geometrical and optical variation driven by form, transparency and color variation can drive; limit or control light transmission, reflection and refraction, and therefore carries significant implications for all things glass: aerodynamic building facades optimized for solar gain, geometrically customized and variable thickness lighting devices and so on.”

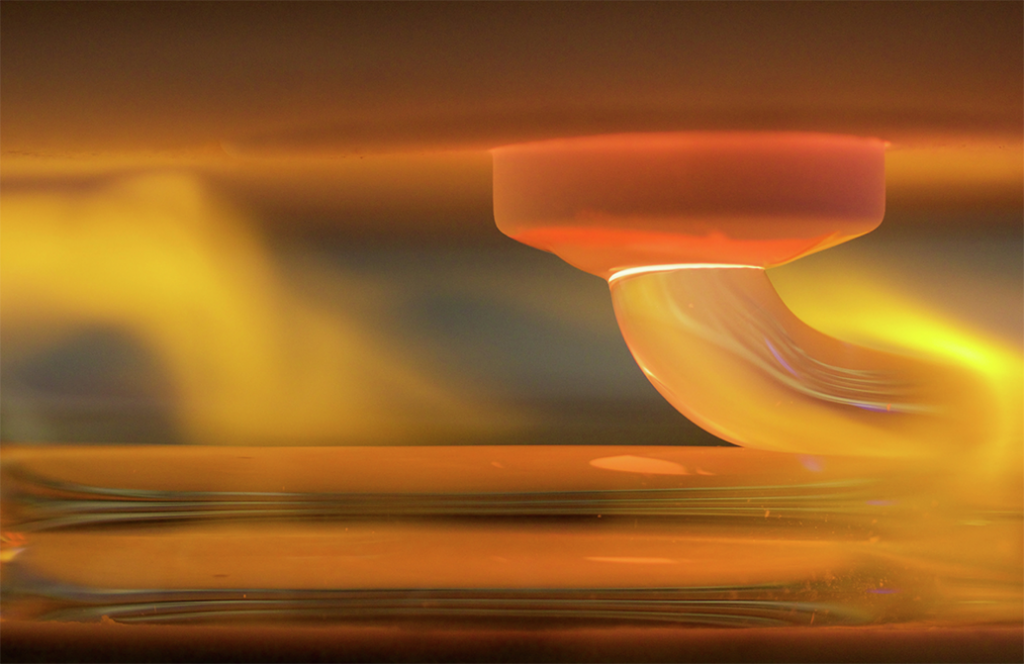

Micron3DP was reluctant to reveal too much about their process, except that their printhead can reach up to 1640° C. In the case of Mediated Matter’s technology, the printer is broken up into two chambers, in which an upper chamber heats the glass before it flows into a second chamber and is extruded out of the printhead. Mediated Matter describes the process in a blogpost, “The upper chamber acts as a Kiln Cartridge while the lower chamber serves to anneal the structures. The Kiln Cartridge operates at approximately 1900°F and can contain sufficient material to build a single architectural component. The molten material gets funneled through an alumina-zircon-silica nozzle. The project synthesizes modern technologies, with age-old established glass tools and technologies producing novel glass structures with numerous potential applications.”

The process, shown in the video below, could both improve fiber optic design and streamline its use by incorporating it into building construction. According to Oxman, “Now consider printable optoelectronics, or the possibility of combining optical fibers for high-speed data transmission by light, combined within glass printed building facades. Or consider the possibility of printing spatial pockets and channels containing photosynthetic media. Think Centre Pompidou without functional or formal partitions. Instead consider a single transparent building skin that can integrate multiple functions and can be shaped to tune its performance.”

With this technology, the group will begin to test various architectural systems relying on 3D printed glass parts, which will allow the MIT group to design geometrically complex components, including structures with internal channels for distributing air, water, and biological matter in unique ways. And, because of the design-to-manufacture process involved, all of this could be customized for a given project or client.

Of course, those that are no strangers to 3D printing know that Prof. Oxman is no stranger to it either, often utilizing the Objet500 Connex series to 3D print fascinating pieces of furniture and bioware. She’s certainly not limited to a specific 3D printing technology, however, even using silkworms to construct a pavilion. It should be no surprise that the professor and her team, then, have polished off glass 3D printing to such a beautiful degree. Of course, she didn’t do it alone! The other members of the team include: John Klein, Markus Kayser, Chikara Inamura, Giorgia Franchin, along with Michael Stern (MIT MechE), Shreya Dave (MIT MechE), James Weaver (WYSS Institute, Harvard) and Peter Houk (Director, MIT Glass Lab).

Though G3DP may make its way into an important building or product near you some time soon, you’ll also get a chance to see pieces fabricated with the tech at the Cooper Hewitt, Smithsonian Design Museum in 2016. Until then, you can read all about the research behind the tech in the September 2015 issue of 3D Printing and Additive Manufacturing (3DP+).