3D printing and Brexit, who knew the two would come together again so soon?

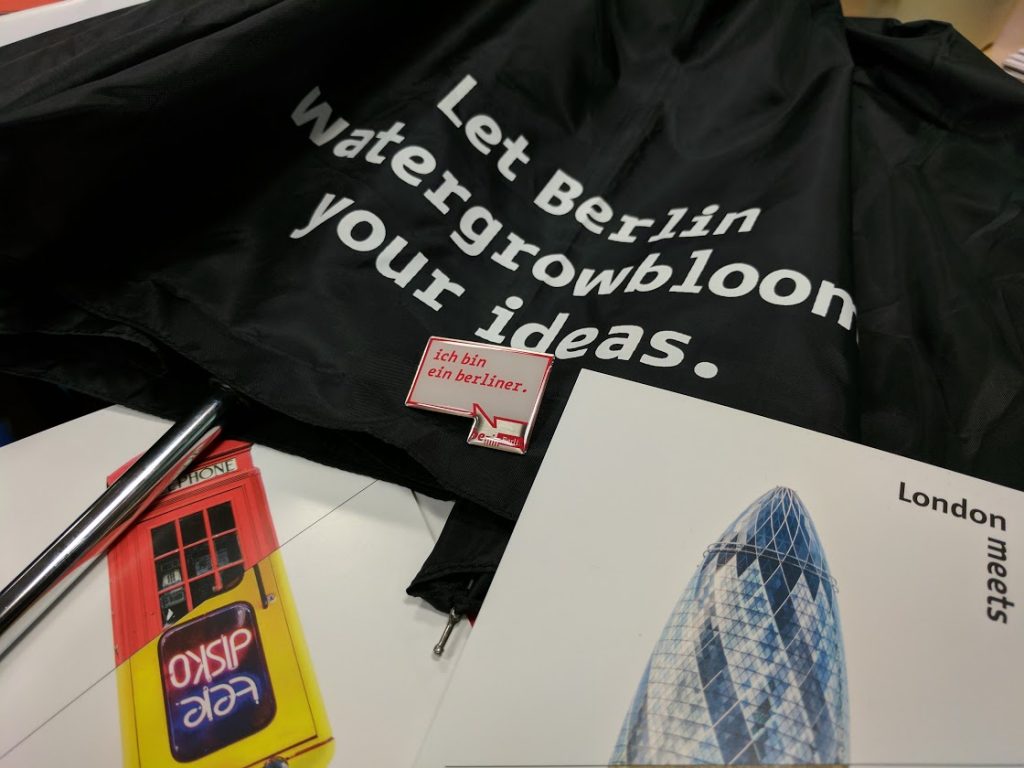

With the unemployment rate in Berlin running at almost than double that of London and seeking to exploit uncertainty after the results of a referendum on remaining a member of the EU, a PR firm hopes to lure UK tech companies to the German capital.

Open until the 26th of November, visitors to the Soho London store can speak with representatives of, “specially selected trends from Berlin’s economy, science, culture, music, gastronomy, tourism, design and sport scene.” This being 3DPI, we headed straight to a Berlin company representing 3D printing: BigRep.

As we recently reported, BigRep are going from strength to strength with recent announcements of two new printers and also a partnership with TNO, a project that aims to make high throughput 3D printing a reality. And also one we expect to hear more exciting news about soon.

Amir Fattal, director of creative projects at Big Rep, was in London this week to speak about how the company are using their 3D printers and in-house know-how to help enterprises such as automotive manufacturer BMW rethink what is possible.

Speaking with Fattal he explained that working with BMW’s prototyping lab in Berlin they were able to show the car and motorbike manufacturer how 3D printing could rapidly accelerate the design process. To illustrate this point BigRep have brought parts of the 3D printed BMW motorcycle with them to London. Each part took 8 hours to print.

BigRep have also recently worked with CJR Propulsion in the UK, a company making steering gear for luxury yachts and work boats. Fattal explained that the custom made propellers would typically take 4 weeks to produce from a wood model to final product, using traditional methods were long delays were common between stages. 3D printing has reduced time this to a matter of days rather than weeks.

CJR Propulsion have even started to work on projects they would not usually undertake, either due to cost or time factors, because of the efficiency savings 3D printing has enabled. As the company explain, “This is something new that we wouldn’t have be doing without a 3D printer because its so cheap and easy to make the patterns we can experiment with many different designs.”

According to Fattal, BigRep are addressing all sides the “3D printing triangle. Hardware, software and materials.” And according to rumors during formnext, more news about the company will be coming early next year.

To be the first to hear all the latest 3D printing news, subscribe to our newsletter here.