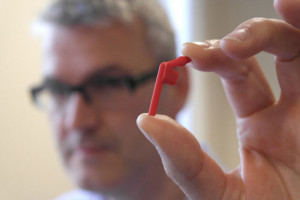

If you want to get 3D printing into end-use production for aircraft, whether it’s for free media coverage or to prove that the technology is efficient and effective for high-performance applications, you’ve got to start somewhere. BAE Systems, one of the world’s largest defense contractors has gotten 3D printing one step closer to end-use production for its aircraft with the manufacturing of a small plastic window pipe made to keep cabin windows from misting up. The part, which is ready to be installed in the company’s BAe 146 regional jetliner, has already received European Aviation Safety Agency (EASA) Form 1 certification approval.

Now that 300 ft of the vent pipes have been produced, BAE is ready to supply them to customers as demanded and envision themselves as a solutions provider for all manner of aircraft, shifting from their role as an Original Equipment Manufacturer (OEM). With their 3D printing capability, the company would be able to design and source replacement parts, have them manufactured, and ensure certification, with Beard saying, “Having achieved this first breakthrough on the BAe 146 window breather pipe, we are now looking at a range of other 3D Printing opportunities to provide replacement parts across several different commercial aircraft types. This technology offers a potential solution for aircraft parts that are prone to obsolescence, where tooling is unavailable, for quick turnarounds and also for small batch production. It may not be the solution for every part, but where appropriate, it provides a faster route from design to completed parts meaning operators get the parts cheaper and quicker.”

Though the window pipe may not seem all that exciting when it comes to end-use parts, it represents a small step towards greater integration of the cost-saving technology of 3D printing into aerospace manufacturing. If the plastic pipe doesn’t excite you, you may be more interested in the 3D printed metal components outfitted for the company’s RAF Tornado fighter jets that have been tested in-flight. BAE is also researching the 3D printing of large metal components, not unlike Lockheed Martin in the United States. According to Lockheed’s Brian Rosenberger, the end use of such a technique might not be more than five years into the future.

Source: aviator.aero