The University of Amsterdam (UVA) has agreed to license a hybrid stereolithography (SLA) technology to Digital Light Processing (DLP) 3D printer manufacturer atum3D.

Developed at the university’s Van ‘t Hoff Institute for Molecular Sciences, this hybrid SLA process combines photo and stereolithography to enable the production of parts with high-resolution features at scale. Once commercialized, the UVA says the technology could be used to address medical R&D needs, such as the creation of tissue scaffolds or microfluidic devices with clinical research applications.

atum3D’s DLP 3D printing portfolio

Based in the city of Gouda in the Netherlands, atum3D specializes in the development of DLP technologies designed to address serial manufacturing applications. The firm’s main offering revolves around the DLP Station 5-405, DLP Station 5-365 EXZ and DLP Station 5-405 EXZ, 3D printers with build volumes up to 192 x 108 x 450 mm in size.

Thanks to their powerful 405 nm LED light engines and 100 micron x,y resolution optics, atum3D says these systems are capable of achieving “new levels of speed, accuracy and consistency.” The platforms are also open-material, so users can choose the third-party resin that best suits their needs, while atum3D’s Curing Station is designed to help users automate the entire production process.

Leveraging atum3D’s technologies, users have been able to manufacture parts with applications ranging from automotive to medical, with the likes of Spentsys developing patient-specific orthopedic devices. To facilitate the deployment of its products in as many verticals as possible, the company also issues dedicated ‘Excellence Packs,’ which include everything rookies need to get started.

A hybrid SLA-DLP technology

According to the UVA team behind the hybrid SLA approach, current resin-based 3D printing technologies generally enable either high-resolution or high-speed production, but few provide both. With the aim of changing this, the researchers have developed a new process in which composite imaging is used to achieve low-resolution patterns on a DLP projector.

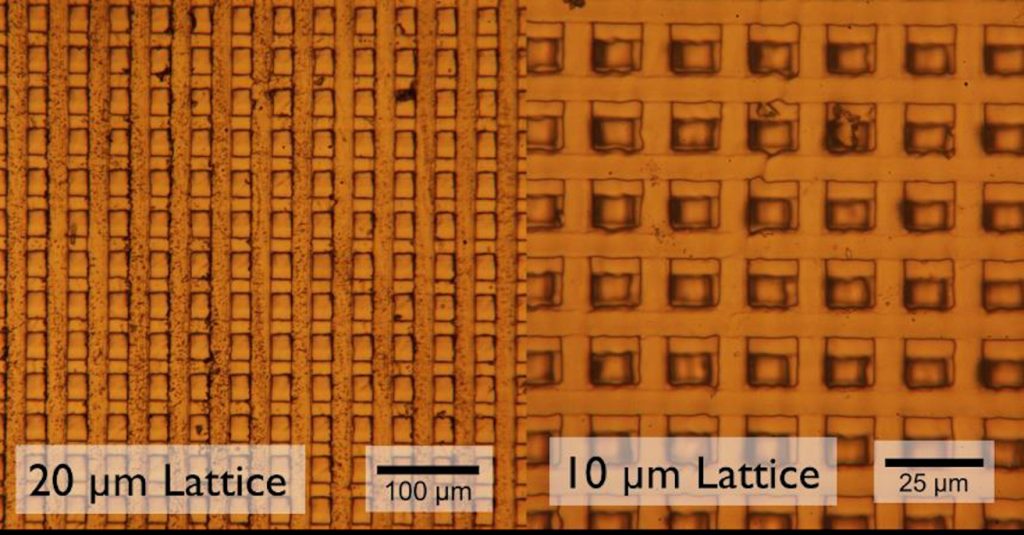

In order to realize micro-features, users can deploy predefined photomasks within these layers, and even switch photomask patterns between layers, to create parts with recurring characteristics. Using the technology, the engineers have so far managed to establish a proof-of-concept setup, which yields objects with feature sizes under 10 μm, but in theory they say its “resolution limit is much lower.”

To assess the process’ potential medical applications, the researchers have also utilized it to create a cell scaffold for a blood vessel junction and a microfluidic device. While the former has proven long enough to foster cell growth and incorporates 50 μm pores, the latter includes 200 μm channels and 20 μm restrictions, designed to facilitate fluid manipulation during clinical R&D.

Having licensed the process, atum3D now plans to integrate it with its own, to address medical, as well as the fields of metamaterial and semiconductor development. Moving forwards, it’s said the technology can be applied in regular DLP systems with only minor modifications, and the firm says it’s already working with initial customers alongside the UVA to develop a practical use case for it.

“We think that combining our current DLP technology with this new technology results in a game-changing platform,” said atum3D CTO, Tristram Budel. “It brings possibilities that the market has never seen before: combining large decimetre scale printing with micron size features and all that in just a couple of hours.”

Although hybrid DLP-SLA 3D printers are far from the industry norm, there is a precedent for the combination of the two technologies. AXTRA3D unveiled a Hybrid PhotoSynthesis 3D printing technology late last year, which is designed to harness the benefits of SLA, DLP, and LCD in the same machine, to enable the production of fully-isotropic components.

Elsewhere, the likes of In-Vision continue to work on rapid DLP technologies with improved resolution capabilities over their predecessors. Earlier this year, In-Vision’s Avatar light engine was introduced, complete with a native 4K capability that allows users to cure larger areas of material, and make moving exposures with high optical performance.

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the University of Amsterdam campus. Photo via UVA.