The Chemical Insights Research Institute (CIRI), a non-profit arm of safety research specialist Underwriters Laboratories, has found that 3D printing emissions can be damaging to human health, even in small quantities.

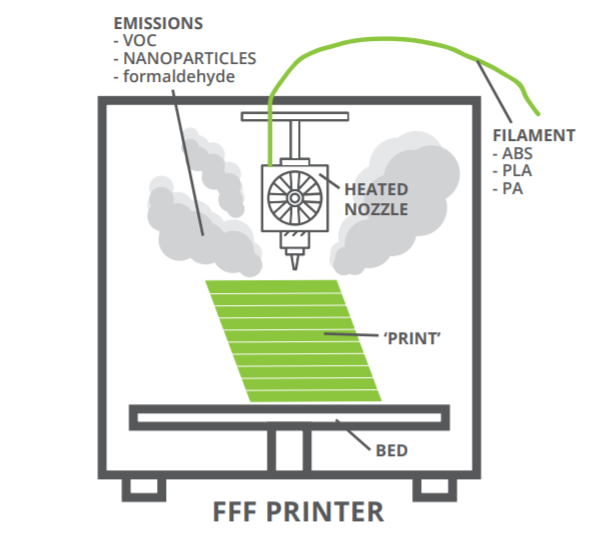

In a recent CIRI toxicity study, researchers found that exposure to the fumes created when printing ABS or PLA filaments, can “contribute to airway cellular injury and inflammation.” Based on their research, the scientists say that operating extrusion 3D printers from a safe distance, as well as ventilation and filtration mitigation strategies, should be discussed in the safety guidance around these machines.

Getting to the bottom of emissions

According to the researchers behind the paper, Dr. Christa Wright, now formerly of Georgia State University, and CIRI graduate student Jennifer Jeon, their study was prompted by concerns over the harmfulness of fumes emitted by certain printers.

Specifically, as FFF systems heat, cool and manipulate filaments, the scientists believed that the chemical compounds released into the air could be “hazardous” to operators. Given the growing popularity of 3D printers in STEM educational settings, the pair therefore said it was “essential” to find out which materials and conditions caused most risk, as well as the consequences of breathing in fumage.

To find out, the researchers cultured small airway epithelial cells in a dish before exposing them to the particulate matter generated via the 3D printing of ABS and PLA, and examining their responses. The team then measured particle emissions over three hours and fed them into a Multiple Path Particle Dosimetry model, capable of determining the impact of prolonged exposure to these, to users’ lungs.

The CIRI study’s toxicity findings

Carried out in July 2021, the researchers’ experiments confirmed their fears about the damage emissions could be doing to 3D printer users’ lung cells. Those samples exposed to high doses of ABS printing fumes exhibited a 49.5% decline in viability, and even the dishes further away or in adjacent rooms were affected, albeit to a lesser extent.

The team then turned to metabolomic profiling, a process in which cells can be assessed for high levels of metabolites, the metabolism byproducts associated with cell injury and inflammation. In the case of PLA and ABS, testing showed that fumes emitted when printing these caused cells to be “altered,” with prostaglandins, compounds that target injuries or infections, being impacted in particular.

Interestingly, while the scientists’ research showed that both PLA and ABS fumes can be “associated with a decline in airway cell viability, oxidative stress, an increase in DNA damage, and high levels of metabolites,” it found that ABS had higher toxicity, as particles collected further from the printer caused more damage to viability.

In light of their findings, the researchers aren’t calling for anything too drastic, like reviewing the 3D printing of ABS or PLA in STEM settings. Instead, the duo say issues like proximity and opportunities to disperse harmful fumes should be discussed in machine safety guidance, to educate users on potential dangers.

“ABS filament emissions may be more biologically active than PLA,” the team say in their paper. “Although contaminants were found at the high school site, ABS filament emissions and associated exposures contributed to a significant decline in small airway epithelial viability, oxidative stress, an increase in double stranded DNA breaks, and high levels of the metabolites associated with cellular injury.”

AM emissions: a growing field of research

While it’s relatively well-known that the fumes emitted by certain materials during 3D printing could be harmful, the extent of this danger still isn’t fully understood. Just last year, fume and particle extraction technology developer BOFA International emission research revealed the impact of particulates and gasses emitted, and suggested measures users can take to protect themselves from harm.

Scientists at the US Environmental Protection Agency (EPA) have also previously tried to assess the impact of 3D printing ABS that has been reinforced with carbon nanofibers. Through its 3D printing emission study, the agency sought to develop fresh literature on the topic, designed to help users understand potential issues.

In the past, Underwriters Laboratories itself has published UL standards for 3D printing emissions, to enable manufacturers to mitigate any indoor air pollution risks. Back in 2019, the organization issued ‘ANSI/CAN/UL 2904,’ a document its VP of Standards Philip Piqueira said would “advance the availability of low-emission printers and print media for use in the global marketplace.”

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows researchers working at Underwriters Laboratories’ CIRI institute. Photo via Underwriters Laboratories.