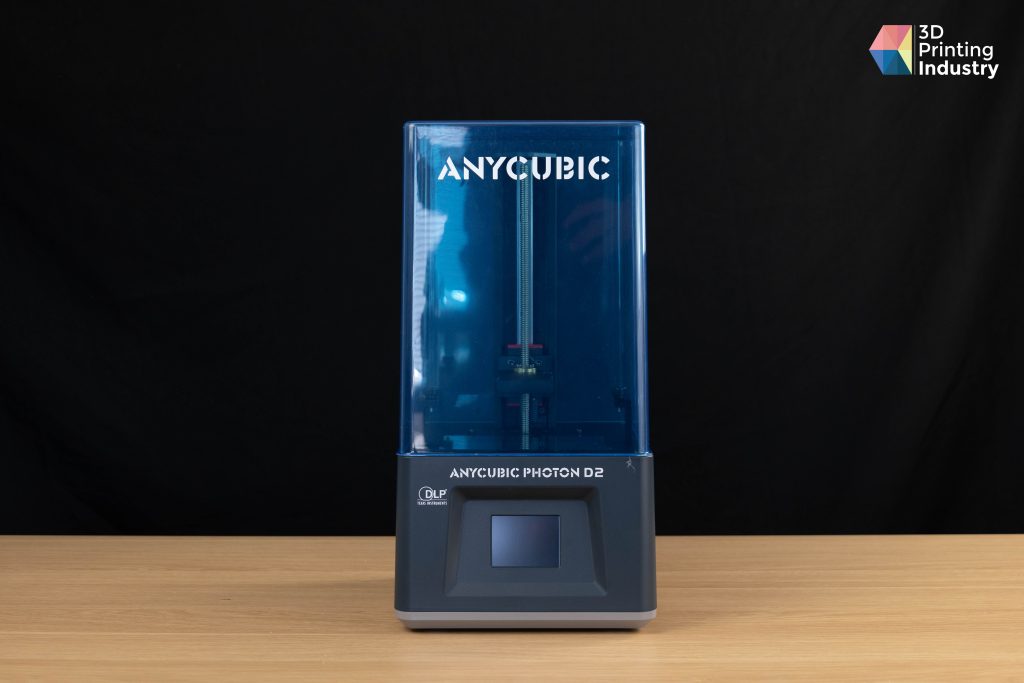

Anycubic is a China-based company operating out of Shenzhen. Founded in 2015, they produce a wide variety of 3D printers and are known as a world leader in desktop additive manufacturing. Anycubic is best known for its Photon range, the Photon D2 model is the next generation of the Photon Ultra. The D2 is more developed and has all the necessary attributes to succeed in the beginner and intermediate markets. Anycubic produces quality products with ease of use and versatility in mind, this is proven by its previous releases, such as the Photon series and the i3 mega.

With their latest release, the Anycubic Photon D2, they hope to penetrate the hobby market, maintaining a large focus on miniatures and detailed part resolution. This printer is the newest in the Photon range after the previous success of the Ultra.

This 3D printer contains some impressive technologies not previously seen on the Photon Ultra.

The D2 utilizes double algorithms to achieve 92% light uniformity using anti-aliasing. This significantly increases the accuracy when printing miniatures.

Lifespan is longer than an average LCD resin printer as the D2 uses DLP(Digital Light Processing), which uses less power and ensures long-lasting quality from the first to last print. Another feature that sets this printer apart from its competitors is the texture of the bed. This is created using lasers rather than sandblasting, this method gives it greater adhesion which in turn makes the printer more reliable.

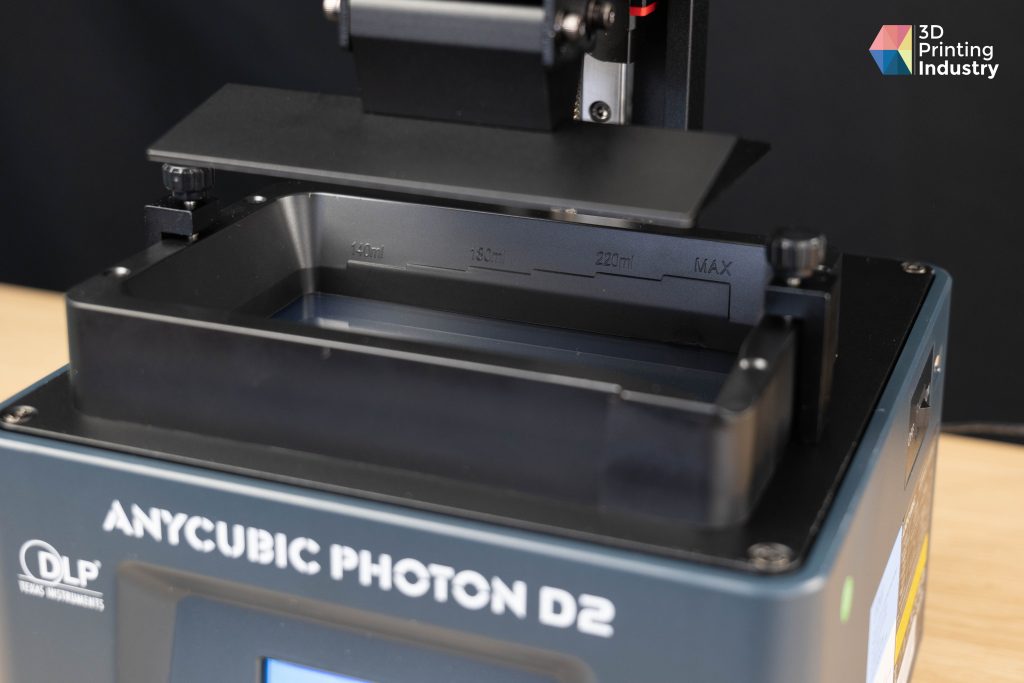

Anycubic Photon D2 build plate & resin vat. Photo by 3D Printing Industry.

Where there are many positives to this printer, it is inevitable that a weak point will be made clear.

In the case of the Photon D2, this lies in the slicer software. The UI of the slicer looks outdated and not in line with competitor packages. There are also limited options to input your own profiles. These points will all be elaborated on in this article, and a conclusion drawn about the machine.

Our initial thoughts going into this review were positive as we have had huge success with the previous machine, the Photon Ultra. We tested the repeatability of the 3D printer producing dimensionally accurate parts. Overhang capabilities, adhesion, and precision were all also tested thoroughly, as this gives us perfect insight into the printer’s abilities.

Key Features of the Anycubic Photon D2

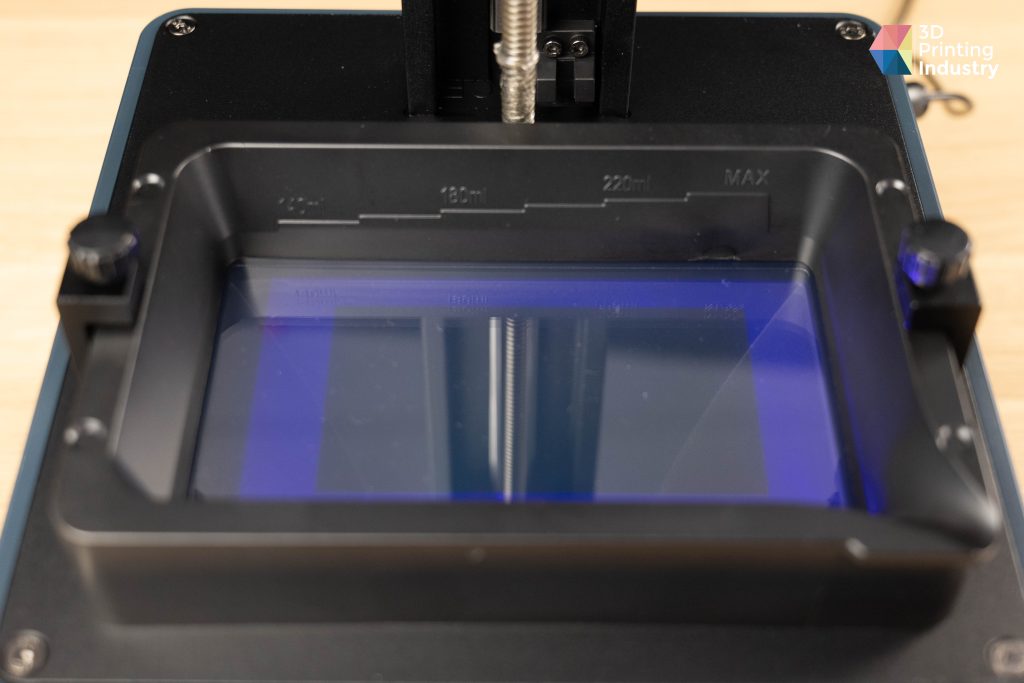

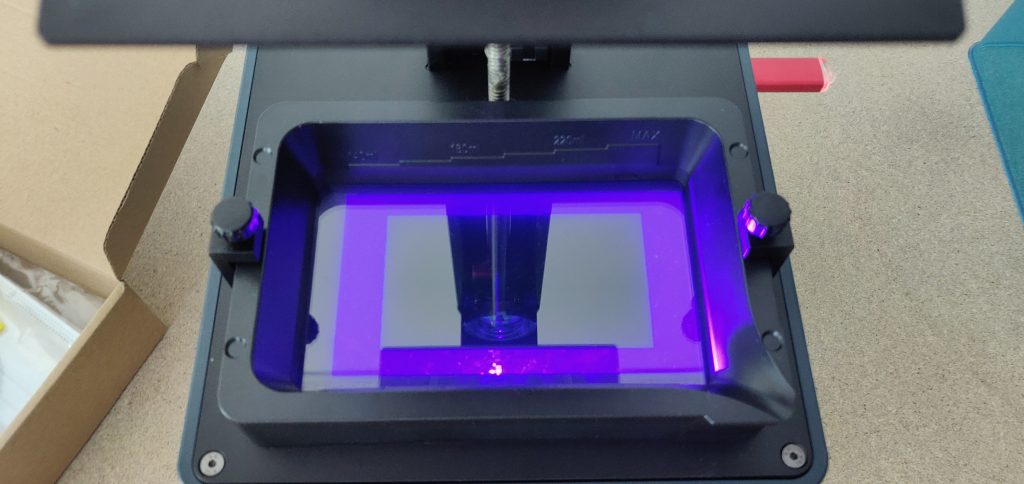

Digital Light Processing is a standout feature on the D2 that is achieved by a partnership with Texas Instruments. The company is famous for its electronic chip systems. Anycubic is bringing this proprietary professional technology to the consumer market. This improves the accuracy of the light rays considerably and ensures the right resin particles are hardened in the vat.

The bed of the printer is machined from aluminum. Lasers have been used to give the bed’s surface a rough but precise finish which is another way this printer stands out from its competition. These measures ensure the best printing environment.

The printer uses a blue acrylic lid placed over the resin vat and bed, this has two purposes. To keep out the UV light that may prematurely cure the resin & stop any dust or contaminants from entering the resin and ruining the prints. Many resin printers have this setup as it is simple and works perfectly for its purpose. The size of these lids is often reflected by the build volume of the printers. The Anycubic D2 has a smaller workspace 130.6mm x 73.4mm x 165mm (5.12” x 2.87” x 6.50”), than other resin printers, but this is made up by the other professional features that are built into the machine.

Anycubic Photon D2 resin vat. Photo by 3D Printing Industry.

The printer can be used with many different types of resin, including third-party brands. The settings can be edited in the slicer with ease, and the same quality results should be produced with any resin used. The printer has an extremely quiet operating volume and uses less power than traditional resin printers due to the method of curing helped by Texas Instruments.

The printer currently sells for around £700-£800 depending on sales or discounts. This printer is a competitive price considering the technology that comes packed inside. Beginner users have found great success with this printer as it is easy to use and intuitive for an inexperienced hobbyist. The Photon D2 is suitable for many users and is marketed toward hobbyists and professionals who need a reliable, hassle-free printer.

Aluminum & plastic are the main material used in the build of this printer as they are cheap, light, and strong. The quality is clear to see when handling the machine and is in line with what you would expect for this price range.

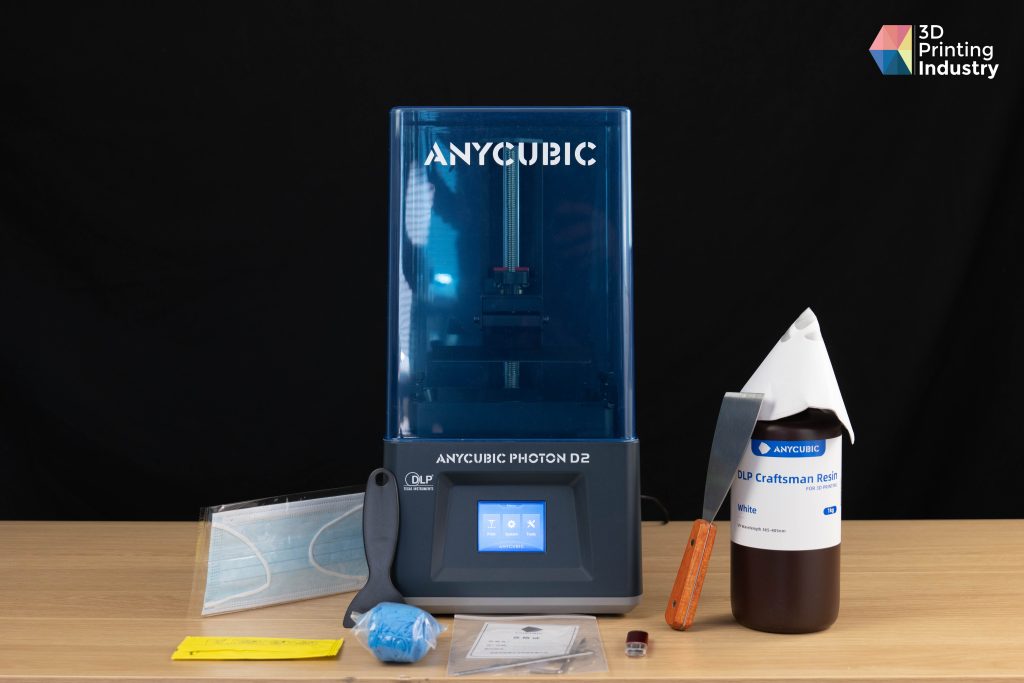

Anycubic Photon D2 unboxing. Photo by 3D Printing Industry.

First Impressions and Unboxing the Photon D2

The printer was packaged very securely, the machine is placed in a cardboard box with numerous soft foam pieces to protect it from any potential damage. Once the printer is removed from the box, there is further protective plastic around the acrylic to stop any scratching or cracking occurring during transportation.

These measures are especially important when shipping from China to Europe. On a resin printer, it is very important the Z axis is protected securely, as this is the most volatile section of the machine. The D2 came shipped with all the usual accessories of a resin printer including a bed scraper, plastic reservoir scraper, face masks, gloves, USB pen & complimentary bottle of DLP craftsman resin. As well as the tools required to assemble and maintain the printer.

The parts were easy to assemble, we had the printer up and running within 20 minutes of the unboxing process, not including downloading software and slicing files.

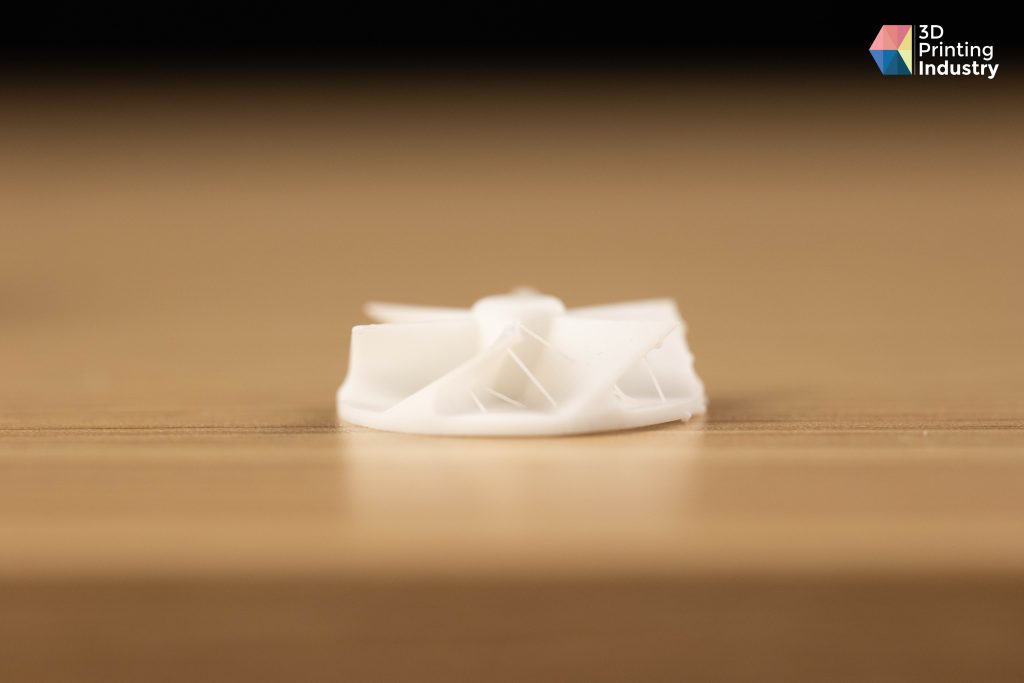

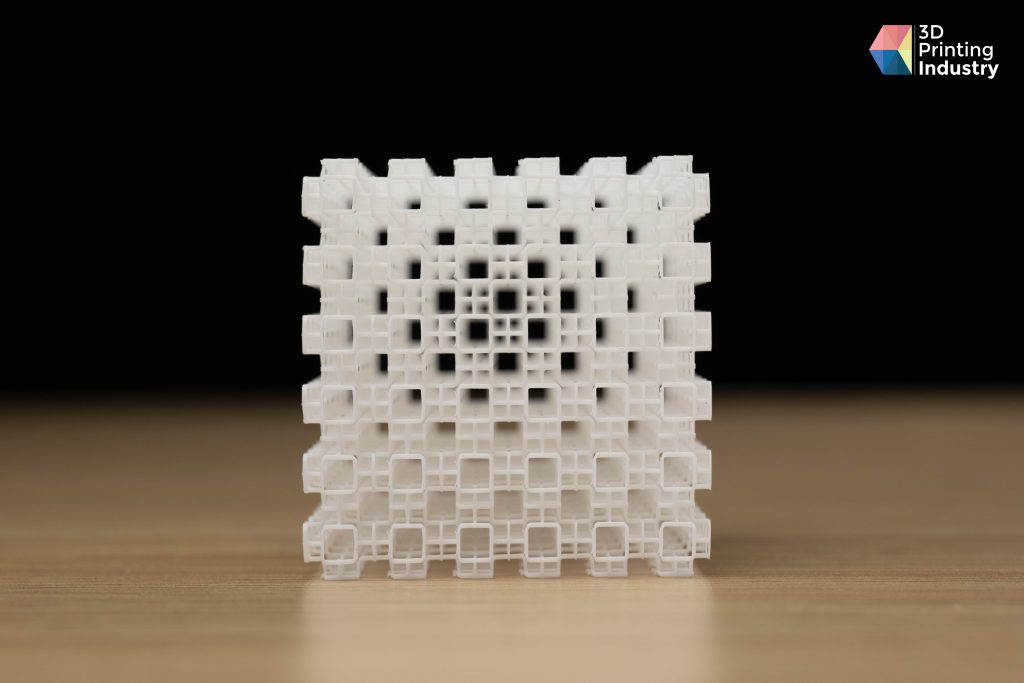

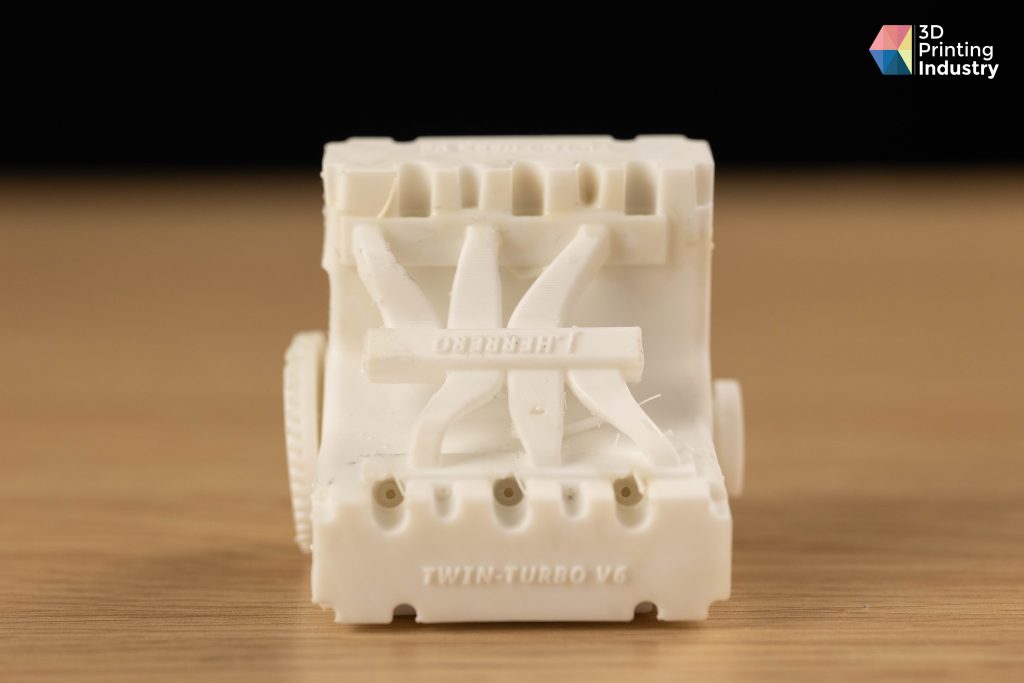

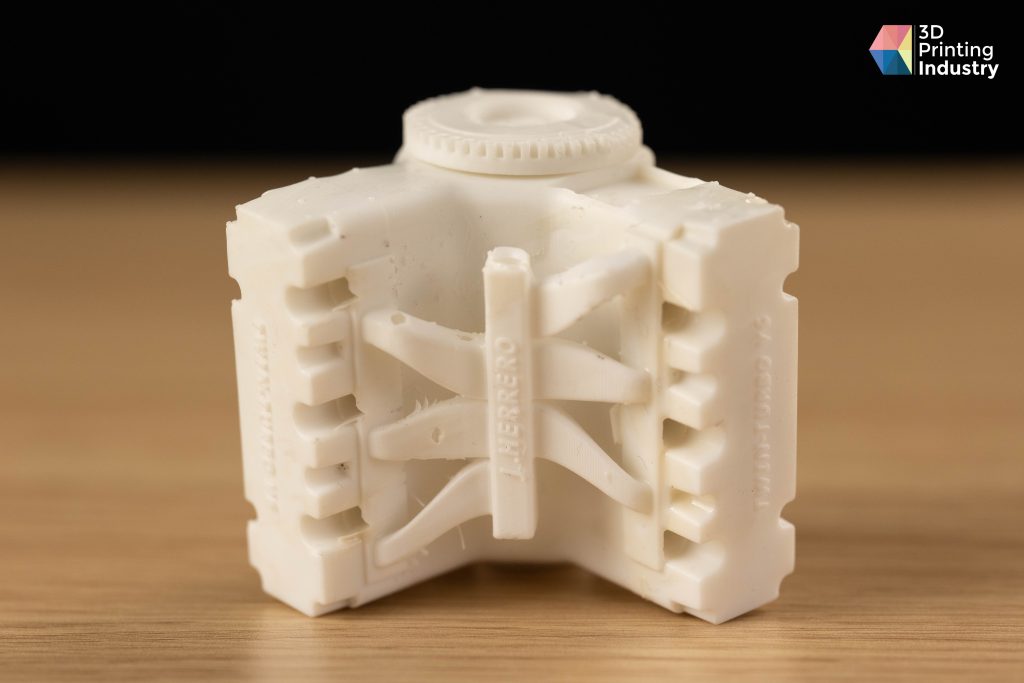

The first print executed was the test file that came with the printer. The test files are usually optimized for the machine and are used to showcase the quality it can produce, given the perfect parameters. The model, as shown below, printed impressively well and was a good benchmark from the printer.

Anycubic Photon D2 first print from SD card. Photo by 3D Printing Industry.

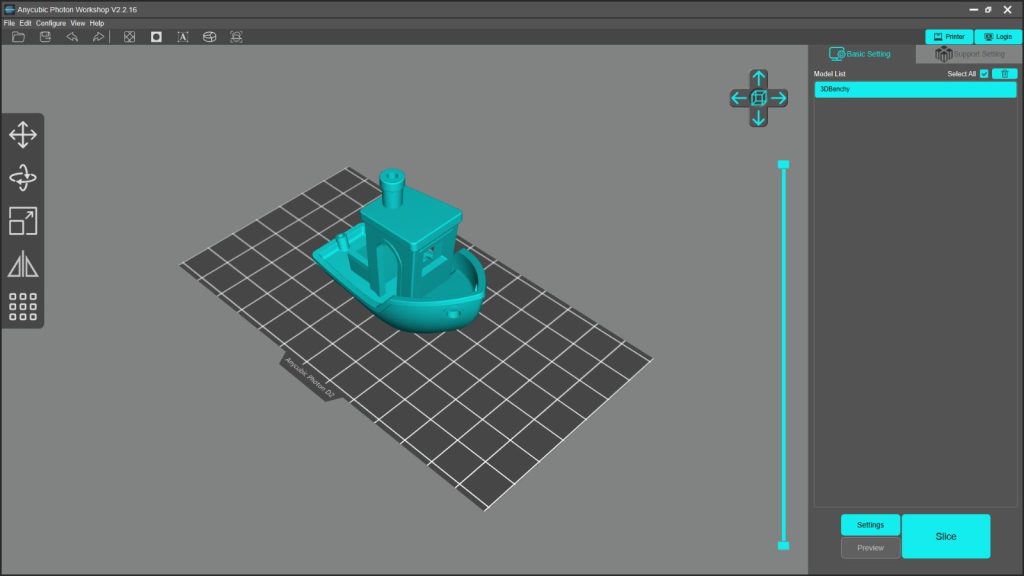

Software and slicing on the Photon D2

Anycubic provides its own slicing software, which is named Anycubic Photon Workshop. The company has developed this slicer, and it’s already well known from use on previous Photon printers. It is popular due to its ease of use but also can be switched to a complex setup for advanced users. Scale, support, and hollowing parts are some of the features available in the software.

Auto-supports can be generated without any input from the user if necessary, but if required, the user can completely control these parameters. This is perfect as it has options for any type of customer and can be a good learning opportunity for someone to slowly explore the more complex settings.

The only thing we noticed that was missing from this software is the ability to generate support for all the models at the same time, the user must do it part after part. It would be interesting to add a button that would allow us to do this with the same parameters on all the parts once they are placed on the build platform.

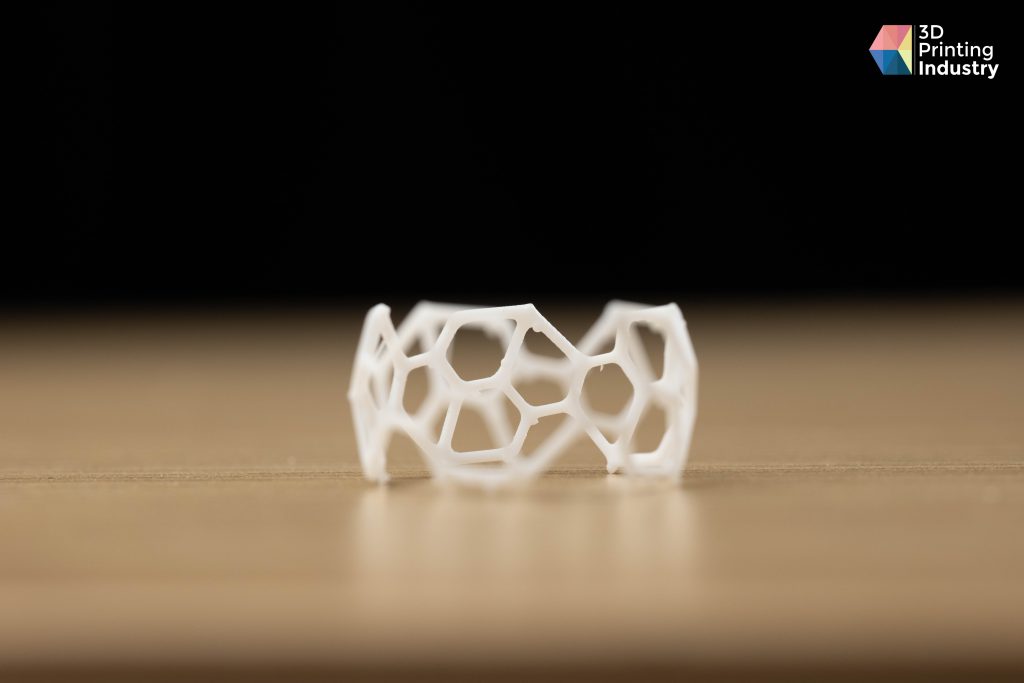

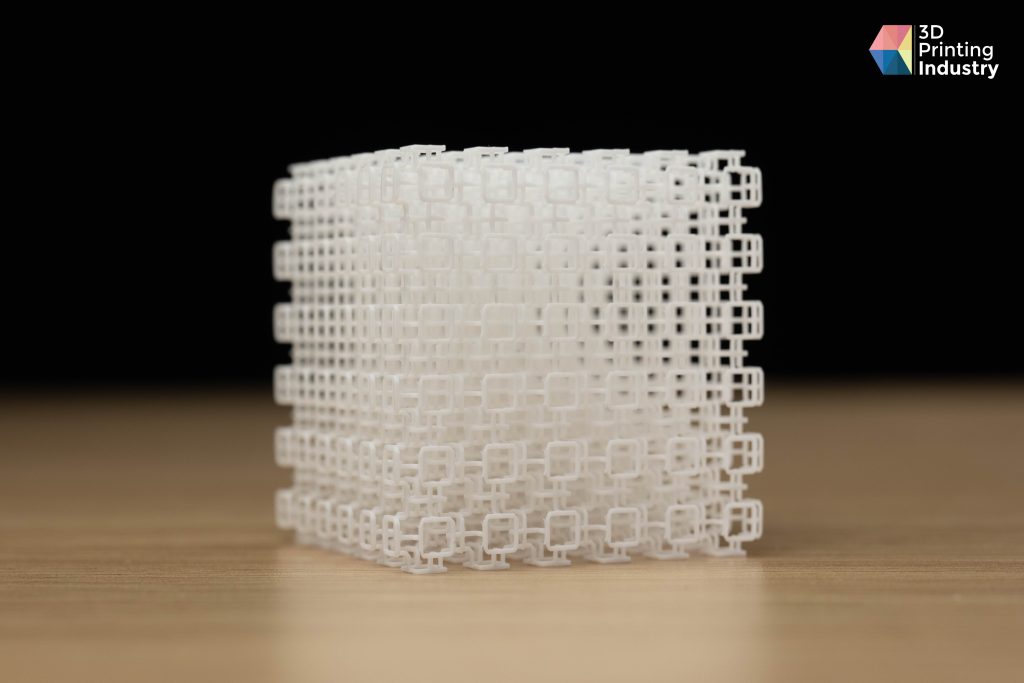

Results of benchmarking and testing the Photon D2 3D printer

Similarly, with our other tests, we always print a Benchy as a benchmark test, the model has a lot of overhangs, circular trajectories, bridges, and holes which often lead to printing issues if not addressed correctly. The dimensions of the print can be measured and compared to the original model to test the accuracy of the machines. The quality of this print was extremely good. One of the best Benchys we have ever printed. There are no defects after post-processing with isopropyl alcohol. This is definitely an impressive outcome from this printer.

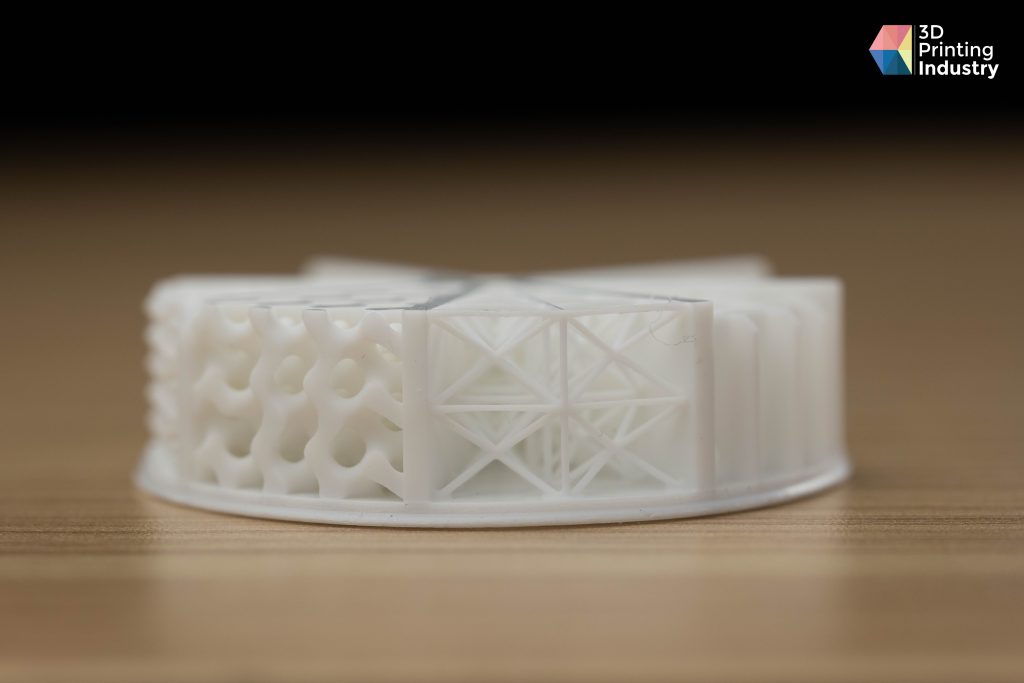

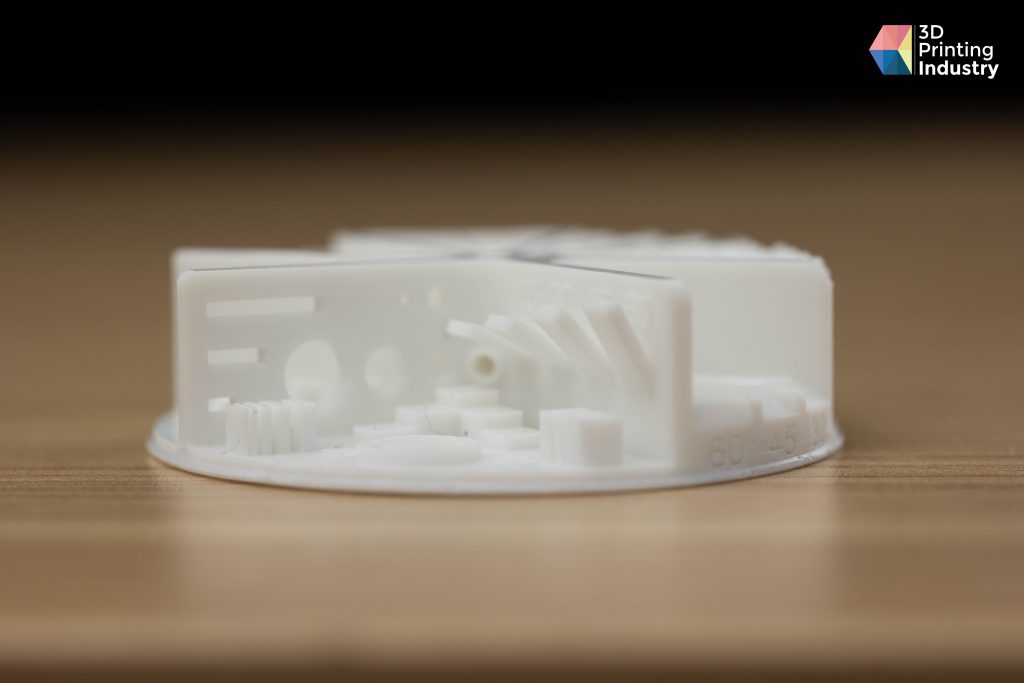

More in-depth benchmarking was taken out on the printer using specific models to measure each individual parameter.

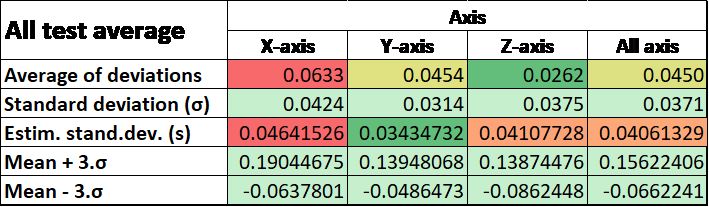

Repeatability was the first test used to test how accurate the printer is over a group of identical parts. The dimensions of the printed parts were measured with a micrometer and compared to the file’s parameters. The average of deviations for all axis is under the target of 0.05mm with a result of 0.0450mm. However, the standard deviation is 0.0406mm, which is slightly over the target of 0.025mm. The results of these tests are very satisfactory but not perfect, as we can see on the X-axis.

It is also very interesting to note that the larger the dimension, the more the printer loses accuracy, for an average difference of 0.10mm for Length (30mm) on the X-axis, the average difference is 0.0408mm for Tube thickness (2mm) on the X-axis. We can infer from this that the Y-axis achieves better results than the X-axis.

During our testing, we found a peculiar result when carrying out the height test. The piece was printed with a Z dimension of 168.5mm even though the workspace of the printer has a 165mm max build height. Interpreting this result, we can confirm that the printer can definitely print at its maximum build height. But this also means that the E-steps for the Z-axis are not correctly calibrated. However, the build volume on the X & Y coordinates also matched the specification.

Unsurprisingly the overhang test produced much the same competent results. Overhangs up to 60° are perfect however, on 65° there is some curvature instead of a straight-angled overhang. The model still completed without failure, but we would classify the overhang limit for this printer to be 60°.

Other tests were carried out, such as precision parts. Resin printers perform well in this area due to the way that they operate. A simple nut and bolt were printed, and again, satisfactory results were achieved, and there were no complaints from our test engineers.

Overall results are very positive for this printer and are competitive considering the lower price mark than competitors that can produce the same standard of parts. All of these parts are measured using either vernier calipers or micrometers, depending on the suitable application. These results are compared with the CAD model’s designed dimensions to produce an accurate benchmark.

Anycubic Photon D2 jewelry prints. Photo by 3D Printing Industry.

Texas Instruments DLP technology

Texas Instruments are a company that specializes in designing, manufacturing, and testing analog and embedded semiconductors. These chips have many different uses, and Anycubic uses this technology to improve its DLP arrangement. Mirrors and a projector are used below the resin vat to ‘sort’ light into a gridlike arrangement to cure the appropriate shape of resin for each layer. In our experience using this printer, it is clear that this works extremely well. Detailed parts such as figurines especially lend themselves to this technology as small details can be picked up exceptionally well.

Overall review verdict for the Anycubic Photon D2

We found no specific shortcomings with this printer which is a huge plus for a machine like this. One thing that could be improved upon is the slicer’s user interface. Compared to its competitors, the slicer could use a visual update as some of the settings and menus are outdated compared to the options and layout presented by newer slicers. We also had slight issues assigning our own parameters to a profile. Both of these issues are easily solvable as long as Anycubic keeps an eye on the issues.

Building on the previous points we have mentioned about the slicer issues, there are no other negatives to this printer that we could find. This is extremely positive.

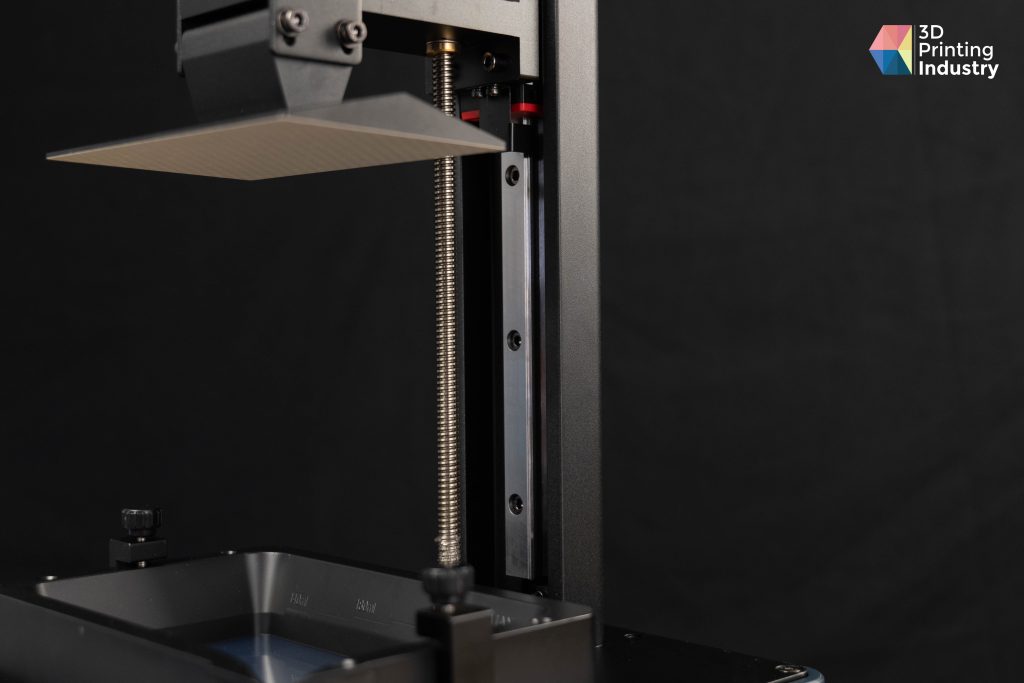

The build platform is robust and permits extremely good adherence due to the specialist laser engraved texture. Moreover, all the components are very well designed. All mechanical parts are optimized for their respective uses. The Z-axis travel is smooth and uninterrupted thanks to the linear rail system combined with the central lead screw. Workspace dimensions, compared to the overall size of the machine, are also very complimentary.

The touchscreen and menu layout is also very easy to navigate, and it is clear that Anycubic has put real thought into the UI of this machine. There is no latency between touch and registration, which is something we see on lower-end resin machines.

Reliability on longer parts is the only real issue here concerning dimensionally accurate parts, but for most users, this will not be a problem. If the user is prototyping large parts on this machine, that would become an issue, but I am sure Anycubic could easily fix this.

The Anycubic Photon D2 is a great printer for beginners as it is very intuitive to use on both the digital end and hardware end. This is a great opportunity for beginners to advance their skills whilst owning a machine capable of complex parts and parameters.

Overall we are very pleased with this printer and the results we were able to produce using it, As usual, Anycubic hasn’t disappointed, and I am sure that this printer will follow in the legacy of the Photon Ultra and be a popular choice for 3D printing enthusiasts.

Buy the Anycubic Photon D2 3D printer here. The system is available to order now for 589€ during black Friday sales.

Anycubic Photon D2 3D Printed Parts. Photo by 3D Printing Industry.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Anycubic Photon D2 with other boxed components. Photo by 3D Printing Industry.