3D printing with silicone is a rather niche area, however, activity does appear to be heating up. The two companies in this news update both offer 3D printing solutions for users who want to access the benefits and material properties of silicones.

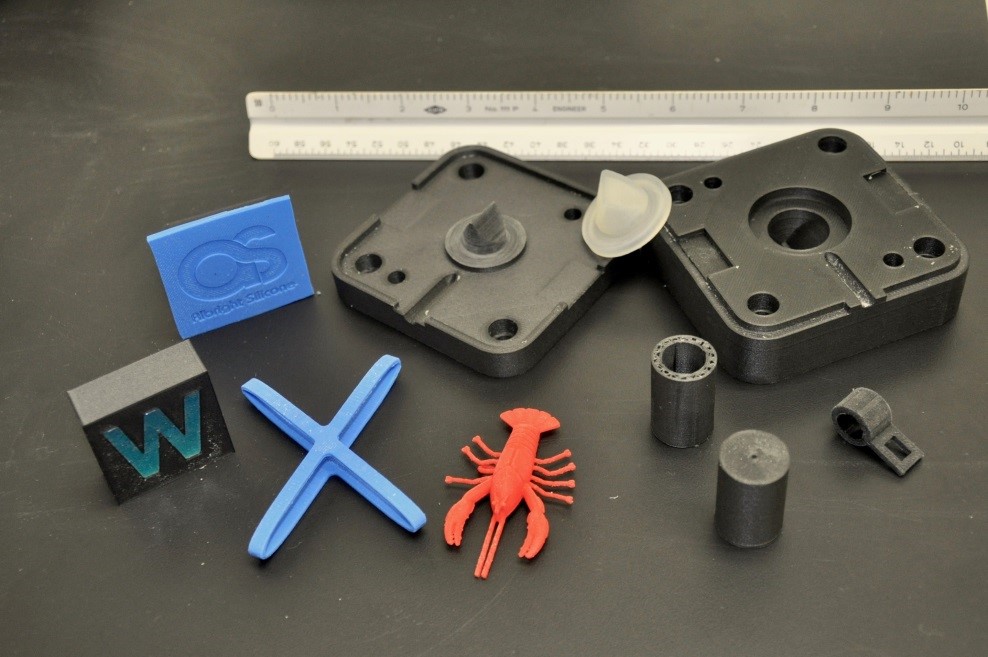

Albright Silicone, a Massachusetts-based engineering company, has launched a new 3D printing silicone capability for customers. Intended for rapid prototyping, the company now provides a service allowing its customers to 3D print tooling for silicone molding using a special 3D silicone molding process. “This capability of 3D printing and molding LSR is a helpful solution to customers’ problems when trying to develop and prove a concept before investing in metal tooling,” comments Mr. Matt Bont, Product Manager at Albright Silicone.

Additionally, WACKER, the Munich-based chemical group behind the ACEO silicone rubber 3D printing brand, has announced a new 50 Shore A version of its ACEO Silicone GP 3D printing material. With the addition of ACEO Silicone GP 50 Shore A to its material portfolio, the company now offers a full range of Shore A hardness silicone materials for 3D printing.

Adopting 3D printing in the silicone industry

Founded in 1995, Albright Silicone initially began life as a plastic prototype molder, however the company shifted its focus to silicone prototypes, molding and production over the last 15 years. The company serves a number of customers in the medical, pharmaceutical, industrial, aerospace and consumer goods industries. Its silicone materials are also ISO 13485 and ITAR certified.

The company is now using 3D printing to produce its LSR castings. With the addition of its 3D printing capabilities, Albright is hoping to serve customers requiring a small number of parts for initial testing, but are not ready for metal tooling. Albright states that customers that choose its 3D printing options can benefit from molding with commercial grades of LSR between 10 and 80 Shore A durometer. Other benefits include color matching, molding components with complex shapes, and molding parts up to 75 mm in size.

Albright is not the only company from the silicone manufacturing industry to have implemented 3D printing within its processes. STERNE, an industrial silicone manufacturer headquartered in the Provence-Alpes-Côte d’Azur region of southern France, has been growing its 3D printing portfolio since 2016. Recently, the company launched a new silicone material for 3D printing, intended for use with its SiO-Shaping system.

Processing silicone materials through 3D printers

WACKER is one of the best-known providers of 3D printed silicone services and materials. Its silicone materials are branded under its ACEO imprint.

Having released its new silicone material, the company now provides 20, 30, 40, 50 and 60 Shore A hardness materials in its ACEO silicone line. As with all the materials in the range, the 50 Shore A version is a real silicone elastomer, intended for high-performance applications in typical silicone industries such as automotive, aerospace & aviation, healthcare, machines & equipment, electronics, and lifestyle.

In July 2019, WACKER announced a range of new products for the K 2019 trade fair in Düsseldorf, including ACEO materials and a silicone 3D printer. The company recently expanded with the foundation of a million-dollar Open Print Lab in Ann Arbor, Michigan. Its first facility in the U.S., the Open Print Lab offers first-hand tutorials and hands-on training for customers seeking to 3D print with silicone rubber.

Silicone 3D printing is a small niche within the 3D printing industry that is experiencing continuous growth. As well as WACKER, Swiss company Spectroplast AG is also offering silicone 3D printing services. The company entered the market with €1.38 million in backing from a seed round led by AM Ventures.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

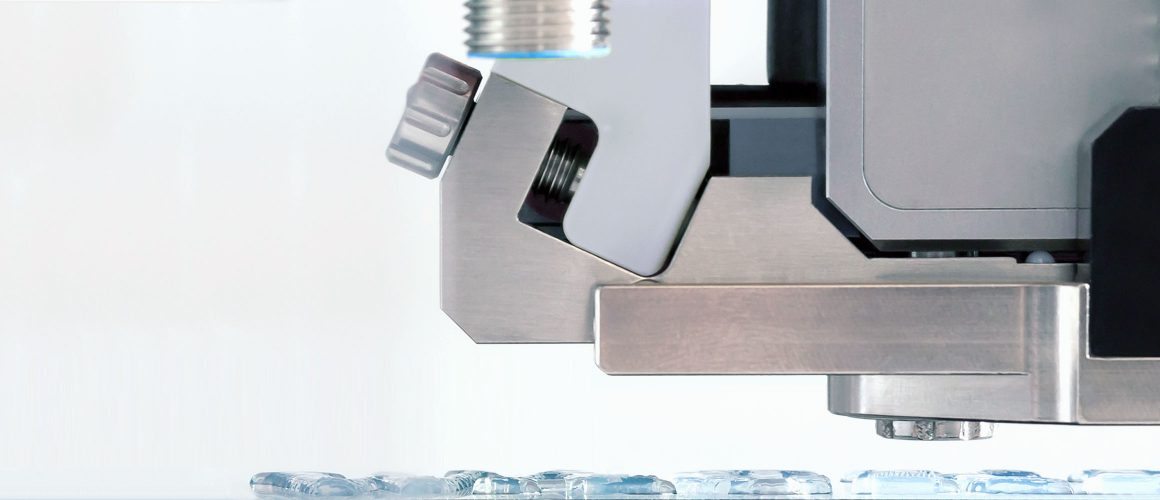

Featured image shows WACKER UV-resistant silicone. Photo via ACEO.