Xaar PLC, a UK supplier of inkjet printheads, has introduced a 5-step service for the evaluation of materials used in advanced manufacturing applications. This service is currently aiding companies focusing on the jetting of fluids with high viscosities.

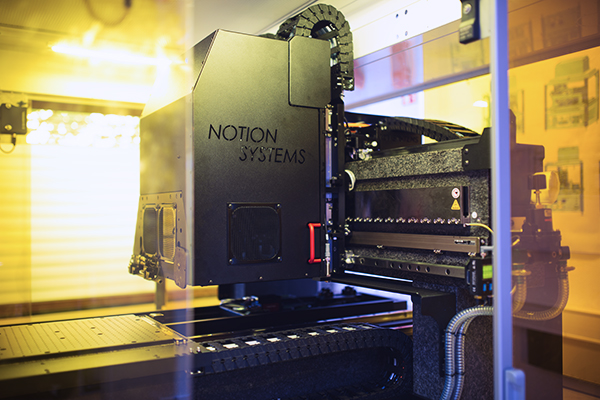

As such, Xaar has invested in a laboratory equipped with testing machinery including an n.jet 3D printer from German manufacturer Notion Systems. Mike Seal, Xaar’s Business Development Manager, Advanced Manufacturing and 3D Printheads, stated:

“Inkjet technology is now highly relevant across a multitude of new product development applications, and we wanted to enable companies to be able to review the suitability of inkjet printing in their product development programs without the need for significant capital investment or upfront costs.”

Inkjet evaluation in 5 steps

The 5-step-service commences with an initial fluid evaluation which provides guidance on issues such as ink development, material compatibility, rheology testing, and fluid physicals measurement. The second stage focuses on printhead waveform configuration, as well as fluid optimization – this is encompassed under jetting optimization. In stage three, fluid samples are produced utilizing custom test rigs. 3D and other advanced sample production are made with the n.jet and Xaar 1003 GS12 printheads.

The n.jet acts as a Photopolymer Jetting (PPJ) machine capable of printing layers between 0.0185mm – 0.0025mm in around six seconds per layer, for features as small as 0.1mm. Within stage four, the samples are upscaled with its application in mind. The fifth and final stage completes each project by providing support and application improvements, testing and advice.

Inkjetting and additive manufacturing

According to Xaar, most inkjet printheads are capable of jetting materials with viscosities with a range of 10-25 mPa.s (10-25 cP). Xaar’s TF Technology is increasing material viscosity as a result of ink recirculation. This process previously enabled the use of high viscosity and high particle-loaded fluids, including refined photopolymers from BASF.

Seal added, “Providing access to our inkjet development expertise through our 5-step service helps clients get to market quicker by reducing their own development timelines and costs.”

“From 3D printing through to functional fluid applications such as optics and flat panel displays, the possibilities and applications for inkjet printing are extremely diverse, and our dedicated team and 5-step service is here to support throughout each development project.”

For all the latest additive manufacturing updates subscribe to the 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook. Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows a scientist evaluating inkjet fluids. Photo via Xaar.