German Chemical group behind ACEO silicone rubber 3D printing WACKER has announced a range of new products to be presented later this year at the K 2019 trade fair in Düsseldorf.

As well as materials, WACKER will debut its new 3D silicone printer, the ACEO Imagine Series K2, which is said to have multi-material printing and novel auto-control technology. Christian Gimber, Vice President of Engineering Silicones at WACKER, stated:

“Product requirements on plastic and rubber materials have risen drastically over recent years. Some standard materials can no longer keep pace with this development. That is why more and more companies are counting on silicone elastomers.”

“Thanks to their outstanding mechanical and chemical properties, silicones have become indispensable for solving demanding technical problems and developing and implementing innovative technologies.”

Silicone 3D printing

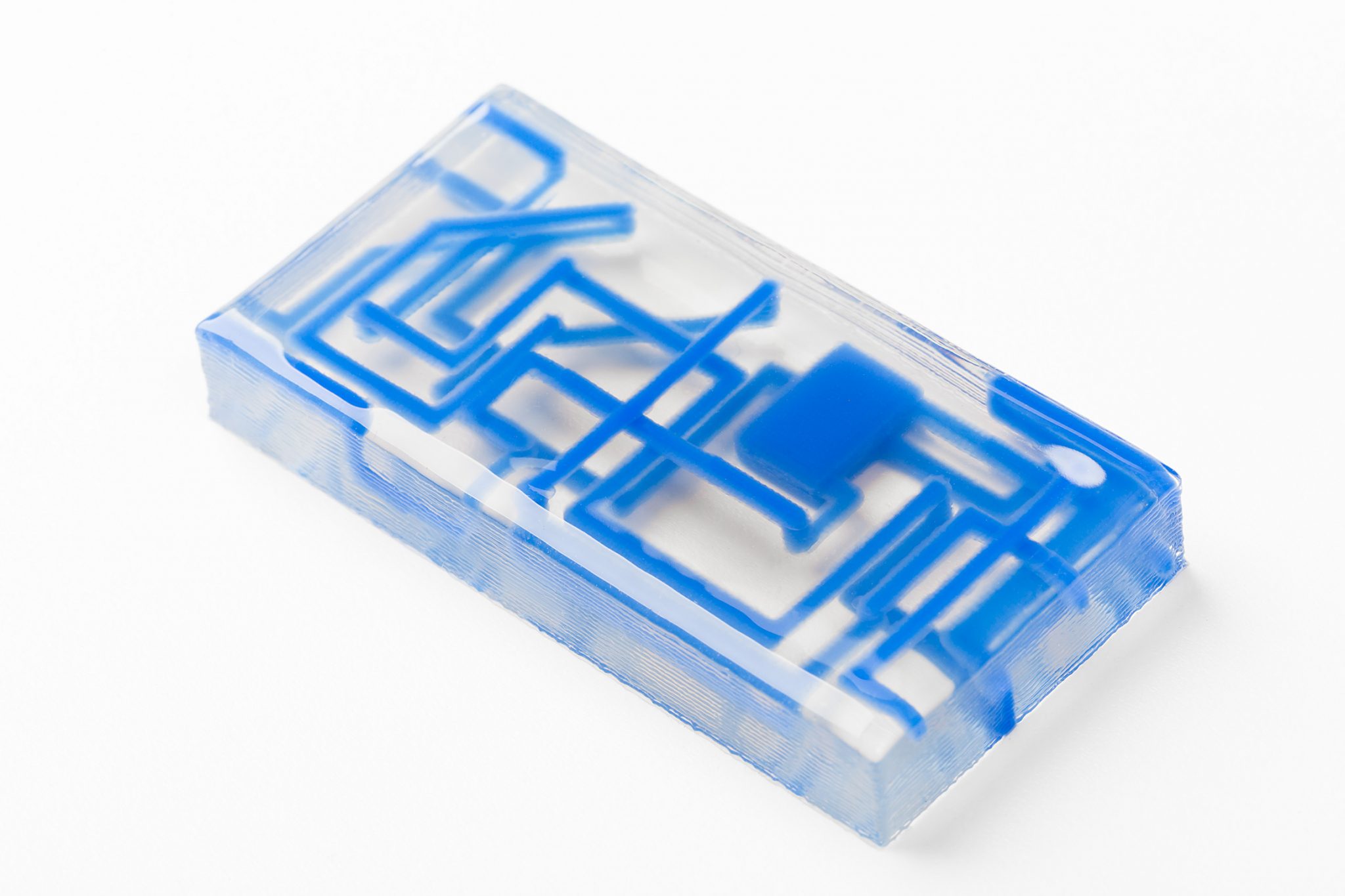

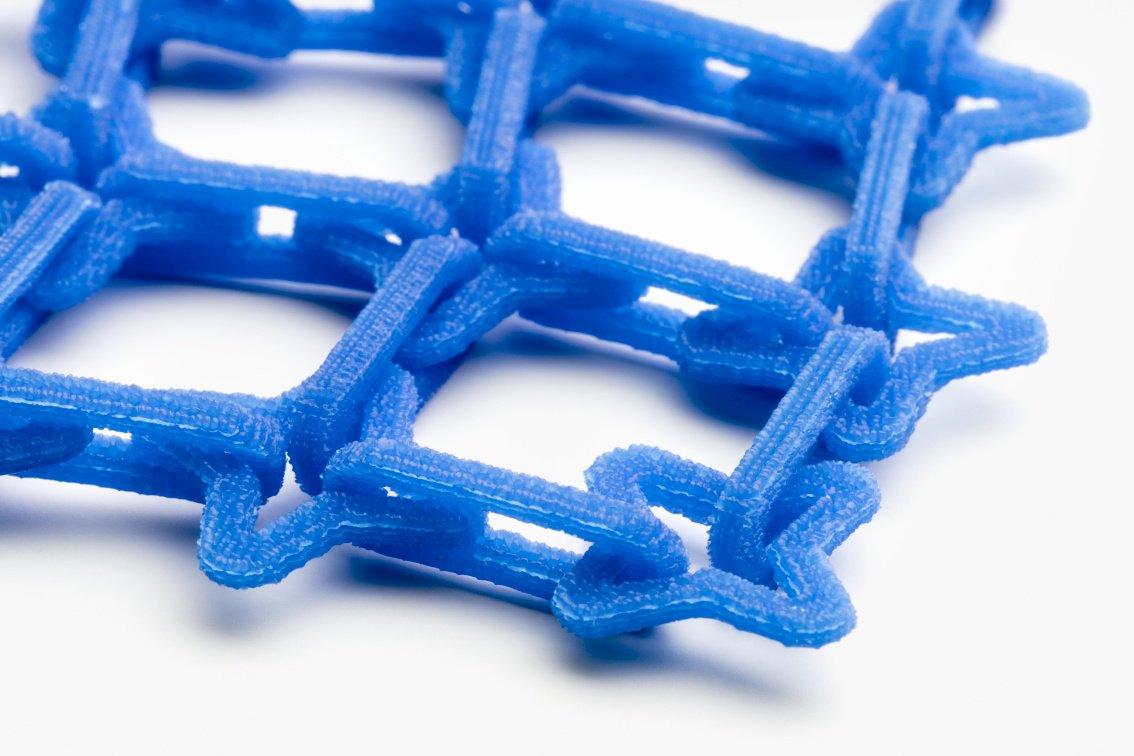

Earlier this year, WACKER opened its first ACEO Open Print Lab in the U.S. at its Silicone R&D facility in Ann Arbor, Michigan, to offer tutorials and training for customers seeking to 3D print with silicone rubber. Its proprietary Imagine 3D printers operate using Drop-on-Demand inkjet technology to additively manufacture highly viscous silicone polymer materials.

The anticipated ACEO Imagine Series K2 is capable of printing up to four different silicone materials simultaneously, enabling objects with different colors and with degrees of hardness, as well as models that require support material. Additionally, ACEO’s new auto-control technology is integrated into this system to measure silicone layers applied with each printing operation and compares it with the target value specified in the CAD model.

This program detects any discrepancies and automatically corrects them with the next layers for extremely precise and detailed 3D printed models. Such elastomeric models have medical, automotive, electrical and commercial applications.

Silicone-based additives

Outside of additive manufacturing, to improve the properties of silicone for electroactive applications, i.e, for battery cooling in electric vehicles, or actuators and sensors, WACKER has refined its ELASTOSIL Liquid silicone rubbers (LSR) line to enable manufacturers of silicone parts to meet regulatory requirements.

Additionally, the company will debut new silicone-based additives materials at the K 2019 trade fair which takes place from October 16th to 23rd. WACKER will be showcasing all of its innovations under the motto “Thinking Beyond” at Booth A10 in Hall 6.

Don’t miss the latest additive manufacturing updates, subscribe to the 3D Printing Industry newsletter and follow us on Facebook and Twitter.

Visit 3D Printing Jobs to find new opportunities in additive manufacturing.

Featured image shows Drop-on-Demand silicone 3D printing. Photo via WACKER.