In 2015, leading chemicals company Wacker Chemie introduced its 3D printing solution for silicones as the trademark ACEO brand. Using on a Drop-on-Demand inkjet approach, the technology presented the ability to design “impossible objects” in silicone for the first time.

Two years later, ACEO has introduced multimaterial capabilities to its proprietary silicone solution. Dr. Bernd Pachaly, Head of Project 3D Printing at the company, comments on the development, calling it “yet another milestone in ACEO’s history.”

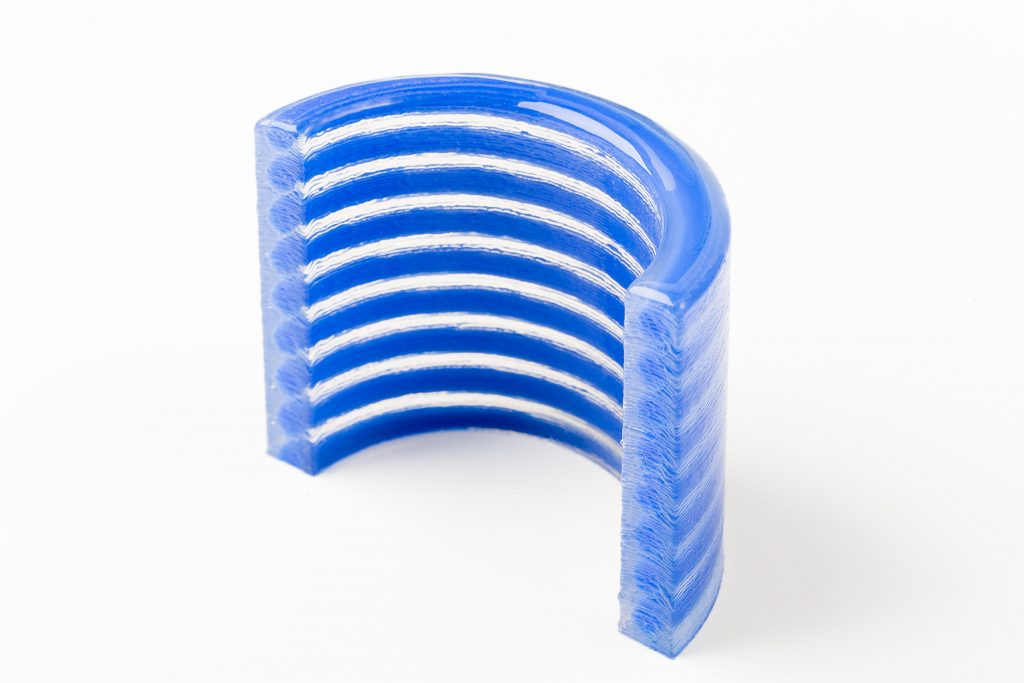

An example of typical 3D printed silicone by ACEO with soluble supports. Clip via ACEO on YouTube

Combining hard and soft

The ability to 3D print with more than one material at any give time means that items made using ACEO technology can be design with graded properties and colors. “Silicones of different colors, hardness or even chemical or physical properties can now be placed independent from each other at any given point throughout the process,” explains Dr. Pachaly, “which allows sharp as well as merging gradients.”

“The result:” he continues, “even more freedom of design in the construction of object with multiple material 3D printed in one single process, in particular soft and hard segments.”

Market demand

Multimateriality has been added by ACEO as a result of market demand. Such versatility is especially valuable in product development where it benefits the production of items such as food safe equipment, medical devices, and scaffolds used in biomedical research.

For Dr. Pachaly, however, its the area of electronics that particularly excites innovation. “To me,” he adds, “the most interesting aspect is that it allows integrated functionality such as electrical conductivity.”

With the multimaterial solution, ACEO can 3D print both conductive and insulating silicones in a single operation, eradicting the need for assembly. As an example, Dr. Pachaly explains, “Think about heating elements or electronic components: you need a wire and an insulating component […] with ACEO®, metals could be replaced with electrically conductive silicones, resulting in one process step without assembly.”

Find 3D Printing on Facebook and Twitter. If you want to learn more, subscribe to our newsletter and check out a 3D printing event near you.

Featured image shows a sample of ACEO multimaterial 3D printed silicone. Photo via ACEO