UK-based post-processing specialist Additive Manufacturing Technologies (AMT) has launched its new Digital Manufacturing System (DMS) at Formnext 2019.

Described as a comprehensive post-processing system, the DMS uses AMT’s proprietary technology to provide an automated and digital solution for the entire manufacturing workflow. Namely, the system was designed to address the manual stages between 3D printers and post-processing machines, in order to “complete the equation” for high volume production applications of additive manufacturing.

“AMT’s unique solutions combine market leading technology, machine learning capabilities, dedicated automation systems and superior research and production partnerships,” comments Joseph Crabtree, CEO at AMT. “It is this approach that means we offer more than just a process or just a machine, which is what you may find on other booths at Formnext.”

“AMT’s Digital Manufacturing System exemplifies this perfectly, with a comprehensive solution that links all of the post processing stages together through intelligent, digital connectivity and innovative hardware.”

Automating the entire post-processing workflow

Founded in 2017, AMT manufactures automated post-processing systems for 3D printed parts. The company states that up to 60 percent of manufacturing costs in 3D printing can be attributed to the highly manual steps of post-processing, explaining that building the component only accounts for part of the equation. AMT therefore aims to “unlock the use of 3D printing for high volume production” and help customers automate their manufacturing workflow with its post-processing systems.

As such, AMT has developed and commercialized its PostPro3D system, launched in September 2018. The PostPro3D is able to finish 3D printed components into a sealed and smoothed part suitable for end use applications using AMT’s proprietary Boundary Layer Automated Smoothing Technology (BLAST) technology.

However, the company explains that the “automation equation” is still incomplete, as manual intervention between the 3D printer and the PostPro3D remains a necessary step. Customers are still required to unpack a 3D printed part and depowder it, or remove resin from the component, depending on the additive manufacturing technology used.

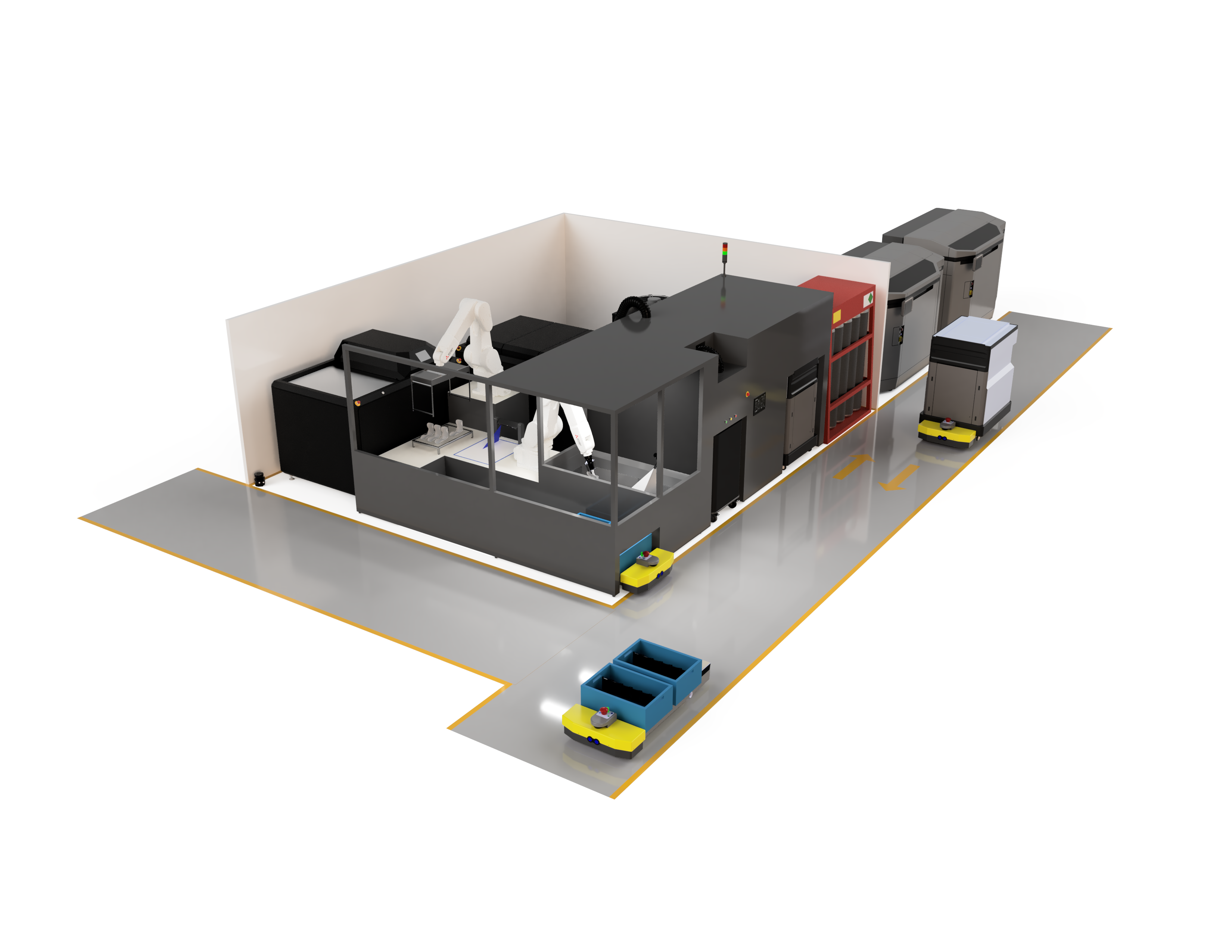

In order to address the entire manufacturing process chain from build to final inspection, AMT has developed its new DMS product to be a fully integrated post-processing system. It uses de-powdering, surface modification, and coloring to automate each of the manual post-processing steps. It can also be customized to the requirements of the 3D printing application as well.

The Digital Manufacturing System

The DMS system uses a proprietary fluidized bed and automated sorting capabilities to unpack a part from the 3D printer. To depowder and remove material from the 3D printed component, AMT has integrated its PostPro3DDP machine within the DMS setup. The PostPro3DDP is a dedicated de-powdering solution for polymer powder-bed AM processes.

AMT has also included its flagship products, the PostPro3D, PostPro3DColor and PostPro3DMini, within the DMS solution to provide automated smoothing and coloring for 3D printed parts. Finally, the DMT system is equipped with a fully automated inline inspection system for quality assurance / quality control (QA/QC), named the PostPro3DMet. It is a machine learning metrology system developed in collaboration with the University of Nottingham.

Global expansion for PostPro3D technology

The DMS system is not the only post-processing solution that AMT has unveiled in 2019. The PostPro3DColor, capable of coloring parts in a single step, and the PostPro3DMini, a smaller version of the original PostPro3D, were initially unveiled at RAPID + TCT 2019 in May.

Recently, AMT announced the completion of a $5.2 million Series A funding round in October 2019. The company stated that it would use the funding to deliver a commercial version of the DMS, as well as accelerate the sales of its other post-processing systems. Following news of the investment, AMT also announced global expansion activities facilitated by the additional funding.

Visitors to Formnext can view the DMS system at AMT’s unique stand, created from over 6000 3D printed parts. The company is located in Hall 12.1, Booth E61.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows AMT’s Digital Manufacturing System assembly. Image via AMT.