One of the most scientifically mind-blowing materials ever discovered, graphene (an allotrope of carbon) has been praised for having an unbelievable combination of material characteristics, including low density, top-notch mechanical properties, thermal stability, and even electrical conductivity. In fact, graphene aerogel is one of the lightest materials ever discovered, reportedly weighing seven times less than air…But these great qualities only really hold true in graphene’s original 2D material composition, which are greatly diminished when graphene is made three-dimensional. That is until now. A collaborative group of researchers from the University of California Santa Cruz’s Department of Chemistry and Biochemistry and the Lawerence Livermore National Laboratory have teamed up to bring 3D graphene into material prominence without compromising the integrity of its mechanical properties, and they appear to have done so using the method of direct-ink writing (DIW) 3D printing.

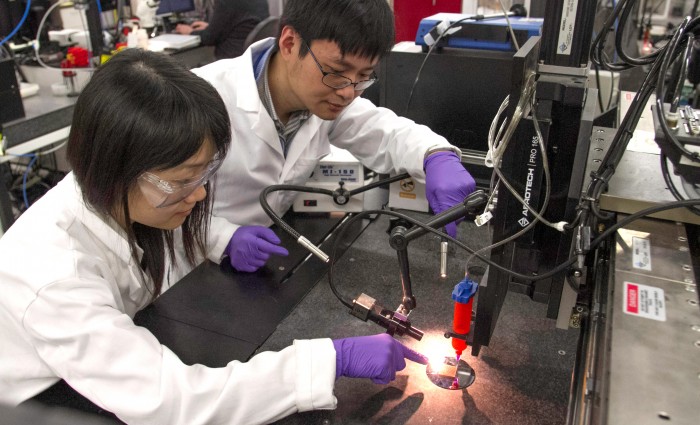

Published in the academic journal American Chemical Society, the California-based research team details their fabrication and testing of their graphene composite aerogels (aka 3D-GCA) via DIW 3D printing. The challenge for the team was developing the graphene composite ink to be successfully extrudable, as well as having to modify the 3D printing process in order to ‘accommodate aerogel processing’. What they found after succeeding in creating the graphene aerogel ink, were the “exceptional capacitive retention and power densities” that are found in graphene’s natural state. The team has already showed their success in manufacturing functional 3D printed supercapacitors out of their newly developed graphene-based aerogel.

“This work provides an example of how 3D-printed materials, such as graphene aerogels, can significantly expand the design space for fabricating high-performance and fully integrable energy storage devices optimized for a broad range of applications,” the research team writes in the abstract of their study.

Although the details of the American Chemical Society’s newly published study isn’t freely available, the abstract provided enough information to infer that this development is a big deal for the expansion of quality 3D printing materials. Using a unique twist on DIW-based 3D printing, this research team has introduced 3D printing technology to one of the most mechanically valuable materials known to humanity. With graphene’s extremely tough and stable mechanical characteristics, as well as its high electrical conductivity, the research team’s innovative material study should certainly improve the material capabilities within a number of industries. Although the academic journal is not freely accessible, ‘supporting information’ on the study is available on ACS alongside the abstract of the study, which provides the material creation and 3D printing process in a bit more detail.