This year, one of 3DPI’s most read articles has been the story of a new glass 3D printing process from Neri Oxman’s Mediated Matter Group at MIT. As researchers and businesses alike seek to expand the material repertoire of 3D printing technology, those at MIT are not the only ones working to 3D print glass. Extruder manufacturer Micron3DP has teased their own studies into the process and Virginia Tech and the Rhode Island School of Design have demonstrated the ability to 3D print glass, as well, launching the Collaborative Glass Robotics Laboratory. In a recent interview with VT News, the lab’s founders detailed their efforts so far.

As the USA’s first lab dedicated to glass and robotics, the Glass Robotics Lab was founded in 2013 through the efforts of assistant professor of architecture and steward of the Design Technology Initiative in the Center for Design Research at the Virginia Tech School of Architecture + Design Nathan King and Stefanie Pender, glass artist and faculty member in the Glass Program at the RISD. And, in the pat two years, the facility has proven capable of making robots that can blow glass, create actuated molds, and 3D print glass.

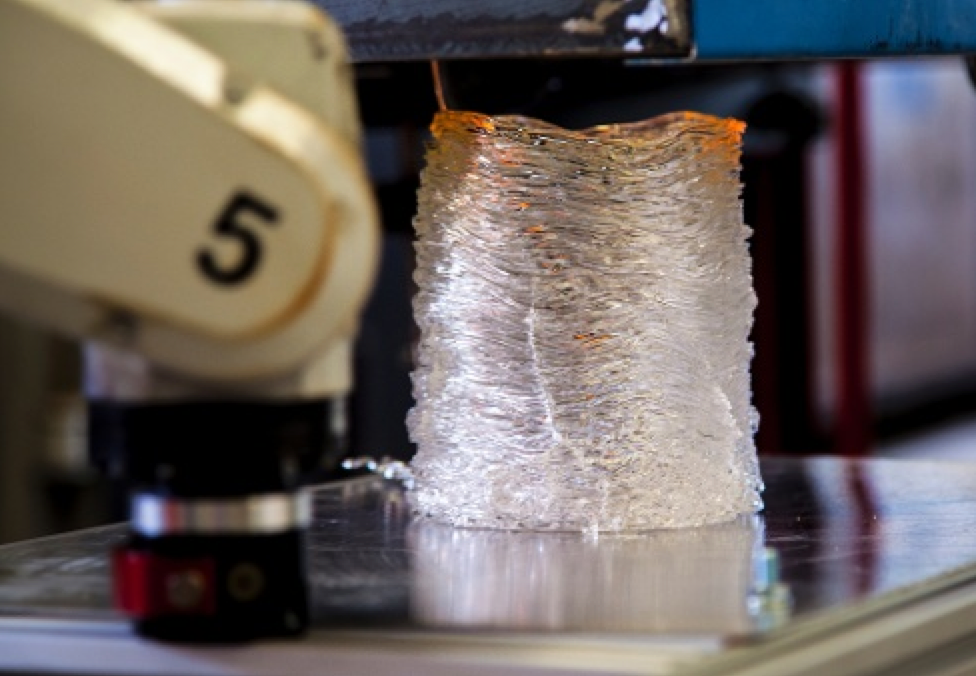

While they’ve demonstrated the ability to 3D print glass since 2013, the studio will be open to students at the College of Architecture and Urban Studies’ Research and Demonstration Facility in Blacksburg, Virginia the coming spring. King tells VT News, “The 6-axis glass-printing process was proven in 2013 and has continued to improve. At this point glass printing has caught the attention of several research groups, each making incremental strides, and each with different goals. The glass robotics facility is the first of its kind research studio and will house a large custom glass furnace, large format annealing ovens, and will utilize the Design Robotics Studio’s large format industrial robotic arm to support the advancement of the mission to realize new potential in glass through the lens of computational design and digital fabrication processes.”

Pender adds, “This research is an example of innovation that can occur at the intersection of art, design, technology, and science. Instead of a technology-driven approach, we can approach digital fabrication from a place of profound material understanding. This research is evidence that the traditional technical arts will not be replaced by digital fabrication, instead, the technical arts will help to drive and support the direction of future making.”

Rather than push towards strict control over the 3D printing process, the Lab is exploring the self-organization of glass material as it is laid down in an effort to understand new patterns and designs made possible by the material. In turn, the lab is allowing their robots to take advantage of these material behaviors. Pender elaborates, “By focusing on the integration of the material and the computational, we can discover generative behaviors within the glass material. For example, ‘transient coiling’ is a mode of movement which hot glass fibers rotate as they come into contact with other materials, thus creating volumetric depth from simple planar movements. The ability to highly control the movement of the glass as it is deposited through robotic control reveals an opportunity to manipulate this phenomenon which would be impossible without an automated process — thus presenting a new design potential.”

Now that glass 3D printing has been proven possible time and again, hopefully we’ll see it integrated into a device that can be utilized by a larger number of people so that we can get this functional object printing show on the road. Then, perhaps, we’ll see 3D printed glass lenses and fiber optics and just about anything you can imagine!