Tractor beams, capable of controlling objects using soundwaves, are no longer the stuff of science fiction or science labs. Thanks to over two years of experimentation from Asier Marzo, and his associates Sue Ann Seah, Bruce W. Drinkwater, Deepak Ranjan Sahoo, Benjamin Long of the University of Bristol, and Sriram Subramanian at the University of Sussex, a portable tractor beam is now 3D printable within your own home.

In this article we explain a little about how ‘the magic’ happens, including exclusive comment from Marzo, the lead researcher on the portable tractor beam project.

Gif shows the Millennium Falcon been pulled into the Empire’s Death Star in Star Wars Episode IV: A New Hope. Clip property of Lucasfilm. Created via: Marcelo Zuniga on Youtube

Tractor beams, how do they work?

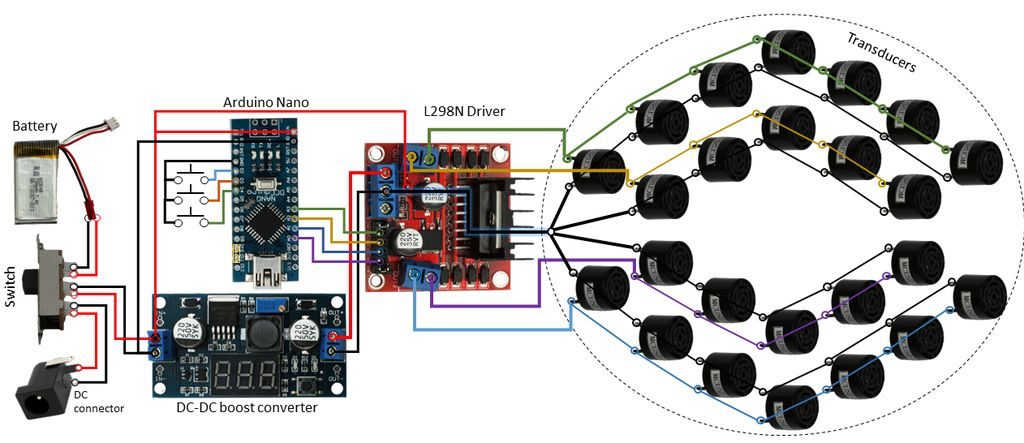

Tractor beams typically work by using beams of radio waves in a phased array structure. This means each transducer (the devices that omit the beams) is set up individually in a different electrical phase. The benefits of such a set-up give the user more control over the waves, and is useful for large-scale typically in the military or aerospace industries.

On a smaller, but not necessarily less industrial scale, phased array setup is not necessary. What Marzo’s method does is simplify the way waves are calibrated, and uses just one driver to control all the transducers. Not only does this mean that it is capable of being made at home, but in Marzo’s opinion it has great potential for application in medicine. He explains:

In my modest opinion, the most important application is using a smaller [tractor beam] to manipulate particles that are inside our body (such as kidney stones or drug capsules) from the outside, without any incision. This is possible since sound travels even better through water or our body than through air.

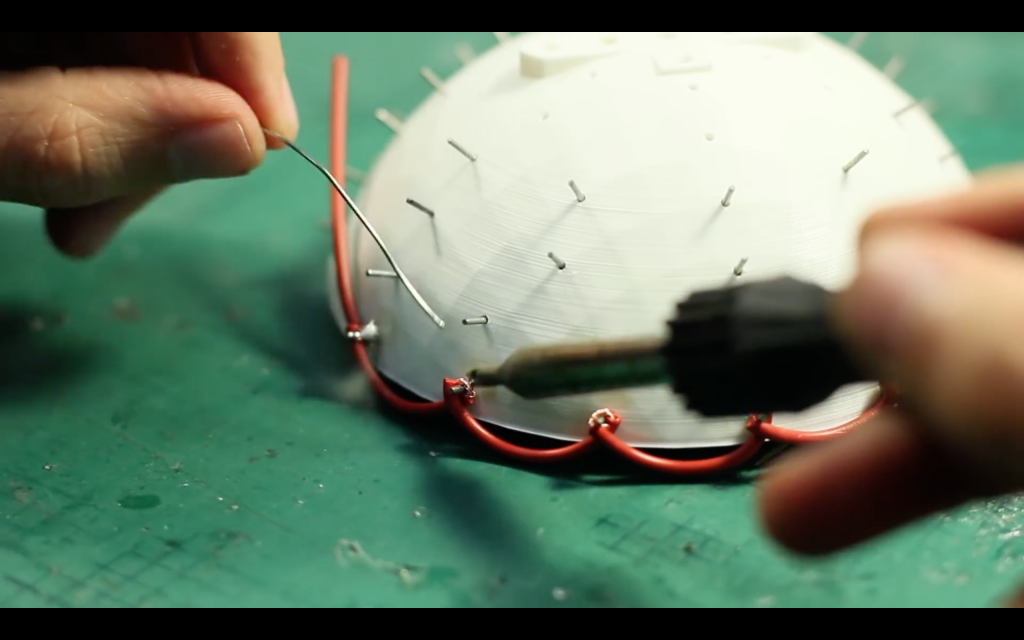

Though a fairly simple approach to making a tractor beam, the 3D printed cup (pictured below) is essential for the setup to work. Marzo adds, “the 3D printed part is used as sockets for the speakers, [which] is more important than it seems because the speakers need to be held at specific positions and angles.”

Once live, the acoustic waves of a tractor beam create a force that effectively traps an object – a concept which is explained further in the paper Holographic acoustic elements for manipulation of levitated objects authored by Marzo et al. and published on Nature in 2015.

A project for the weekend

In a video provided by the Bristol Interaction and Graphics group from Bristol University’s faculty of engineering, all of the electronic tinkering and 3D printing of Marzo’s tractor beam is broken down step-by-step, including only 15 individual components that are either easily attainable online (e.g. an Arduino Nano circuit board), or the kind of kit you’d find lying around your home workshop/local MakerSpace (e.g. a plank of wood, glue gun, oscilloscope for measuring the voltage).

In addition to the cup made to house transducers, the design could be modified to create a more all-round 3D printed product, i.e. a plastic handle to replace the wooden component.

With a bit of know how around electronics and soldering, putting Marzo’s tractor beam together would be no trouble at all, as Tom Rafferty, Chief Technology Officer of iMakr UK explains, ‘the tuning of each transducer [done with an oscilloscope] would be the most complicated part’, though he says he’s willing to have a go at making his own with a distinctly Star Wars theme. Of course, we couldn’t resist asking Marzo about one of the most important applications of this work….

How big would a tractor beam need to be to actually pull a Millennium Falcon into the Death Star?

It’s a question we’ve all been discussing around the office but, as Marzo points out ‘Firstly, sound does not propagate in space’. He then went on to add that,

The power required to fight against the propellers of the Millennium Falcon would be huge, sound is relatively weak (Keolian said that it would require a group of 100,000 children screaming at the top of their lungs to power a lightbulb)

With the methods explored in Marzo’s research, “the maximum size of the trapped objects is half of the wavelength,’ so ’40kHz can only levitate particles up to 4mm.’

For trapping something as big as the Millennium Falcon (approximately 35 meters) we would need to use 4Hz which is good because we would not hear it but such low frequencies have some unpleasant consequences in human bodies.

Have any other 3D printing/fantasy tech questions? Share your thoughts with us either via email, Twitter or Facebook and 3DPI will do our best to get the answers for you. Equally, let us know if you think Marzo’s research is worthy of a 3D Printing Industry Award by nominating it here.

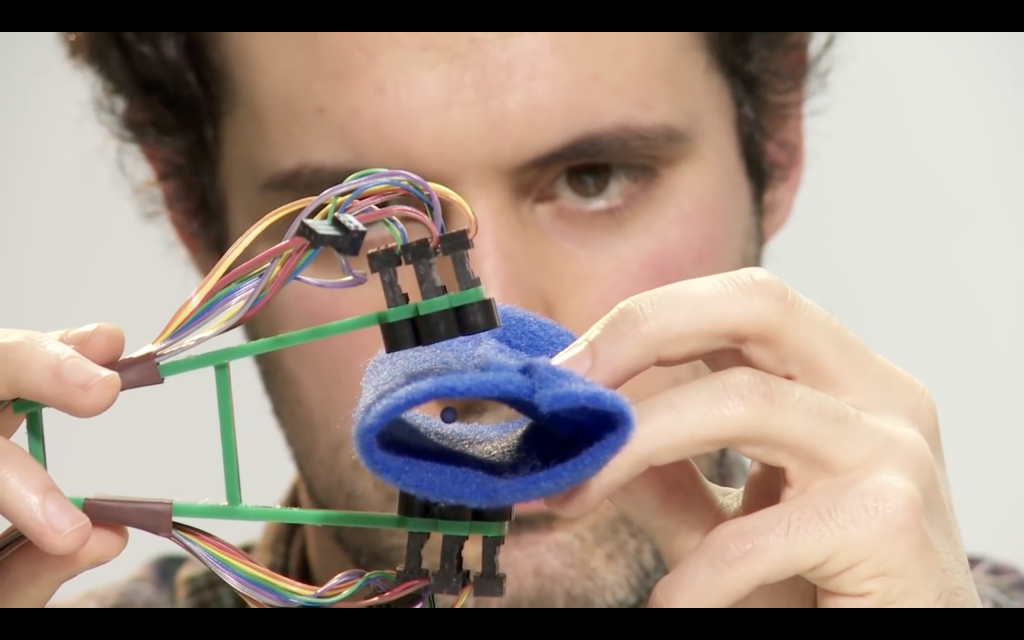

Featured image shows Asier Marzo levitating a polystyrene ball with his handmade sonic tractor beam. Screenshot via: Asier Marzo on Instructables