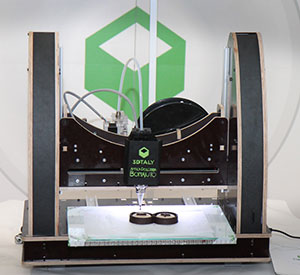

Fans of all that is 3D printing (that definition is getting to be quite large) know that 3D printing technologies applied to food are starting to drive technological appetites. Foodini, 3D Systems’ and the Sugar Lab’s Chefjet, and Choc Edge are leading the way and now two Italian companies, WASP and 3DiTALY have gone to Modica, the Sicilian realm of chocolate, to give it a shot.

“It was a natural collaboration,” said Franco Ruta, the current owner of Old Dolceria Bonajuto, “we happily accepted the challenge. Our conviction has always been that antique does not necessarily mean outdated. Traditions represent a collection of experiences in constant evolution which stem from certain absolute concepts such as respect for the quality of the ingredients and the products specific characteristics. These concepts can and should always be used to experiment and promote new ideas.”

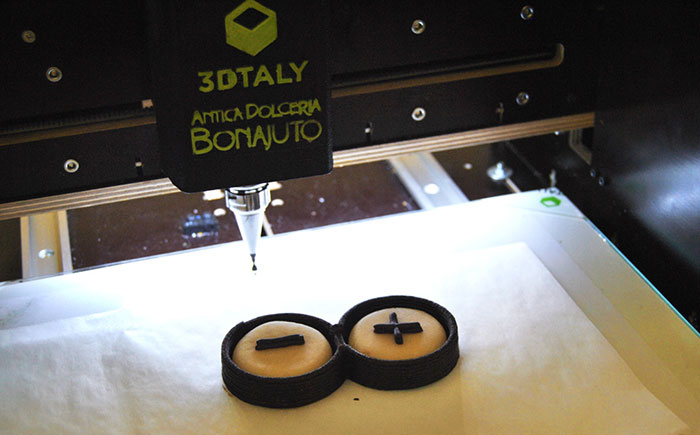

The new idea, in this case, is extruding fused chocolate through the FFF process, an additive process already adopted by other chocolate 3D printers. It turned out to be a particularly good fit for the characteristics of Modica chocolate. This very particular type of chocolate has a very peculiar fragrant and delicate consistency and is produced through a low temperature process similar to that used by the Aztecs.

In Italy food is sacred and some feel digitally manufacturing food will take away from the respect of century-old traditions (something that is reflected in all manufacturing as well). Few places are more attached to traditions than Sicily so this decision to embrace new technologies and to fuse them together with long standing practices and experiences is a great example of what could be achieved. And a tasty one too.