This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

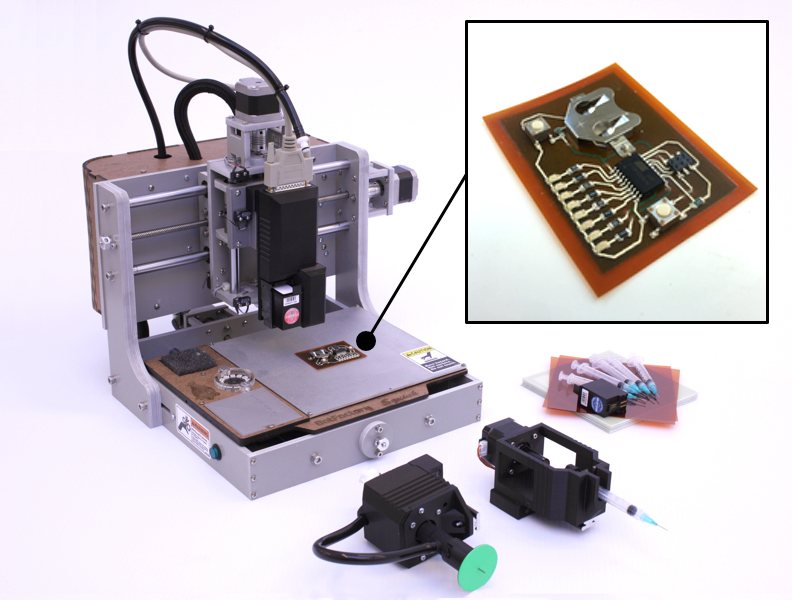

JF Brandon is the VP of Marketing at BotFactory Inc., a New York based company focused on future of electronic circuit fabrication who make the Squink desktop PCB 3D printer.

3D Printing: The Next 5 Years by JF Brandon

Predicting where 3D Printing is going to be in the next 5 years is hard. It was only 5 years ago that Shapeways and Makerbot were small companies – Formlabs had just started out with their first product. The technology was only just beginning to enter the public imagination and for many in the industry today, we were just starting to get our feet wet. 5 years ago owning a 3D printer was an expensive endeavor, but today $300 gets you a fairly decent and reliable printer.

We believe that the Electronics 3D printing industry as it exists today is where the ‘physical’ 3D printing industry was 5 years earlier. Electronics 3D Printing is a method of creating Printed Circuit Boards using Additive Manufacturing (or 3D Printing) techniques. BotFactory is one of a small number of rapidly growing companies, like Nano-Dimensions and Voxel-8, that is poised to crack a very large industry and release the collective creativity of Engineers and Makers. New advances in nano-inks and related 3D printing technologies enable us to meet the very pressing demand for rapid prototyping in the Electronics industry, allowing innovators to imagine and create whole new applications that were impossible with current fabrication methods.

Maturation of Functional Inks

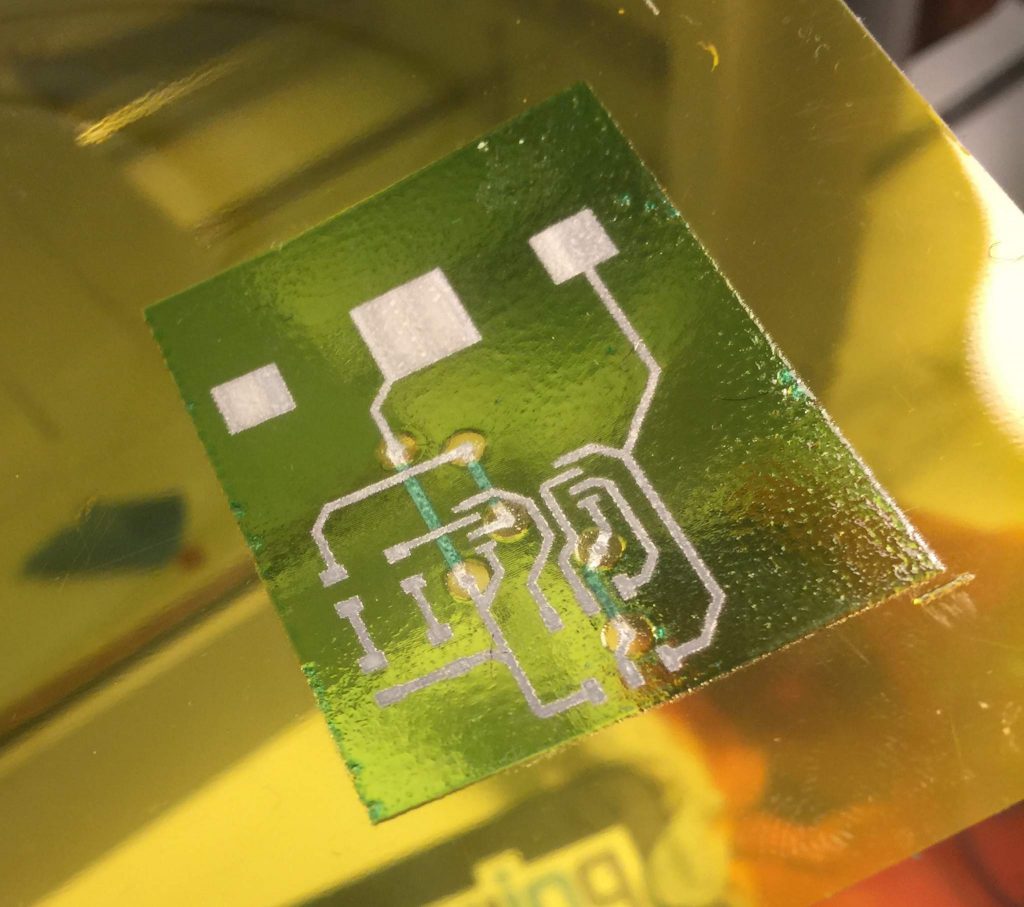

The key element of 3D printed circuits are what we call functional inks, often made of metallic nanoparticles like silver or copper. The technology behind the process of fabricating and dispensing these inks has matured to the point at which reasonably conductive and rugged circuits can be made, but there is a lot of progress to be made still. BotFactory expects that the cost will continue to drop while the overall conductivity and trace quality improves. Dispensing techniques both on the hardware and software are expected to improve and we envision that printed traces will be close to or equal to traditional, subtractive manufactured circuit boards. This is important to the $500 billion dollar Electronics manufacturing industry who desire in-house tools for rapid prototyping and innovative projects.

There have been some advances in novel functional inks like semiconductor inks, and we expect that to continue to occur. The maturation could be revealed in more printed devices, as in printed resistors, capacitors, transistors and LEDs. Combined with the other predictions listed here, there is a promise for creation of novel devices with huge value to the World, although at what scale it is not clear.

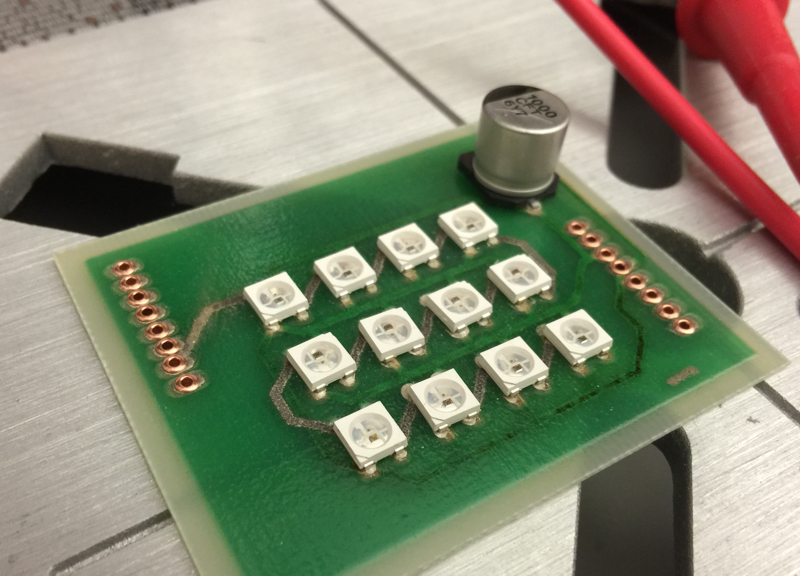

Integration of Assembly with 3D Printing

Within 5 years all PCB Printers will include features like solder dispensing and assembly systems, enabling an Electrical Engineer to create a fully assembled PCBs. Assembly is one of the largest costs of a one-off PCB. Providing a digital-to-physical solution to millions of engineers and product developers would be very valuable in both time and budget savings. Maturation in computer vision software combined with low-cost hardware means that large, room-sized solder-wave and assembly lines can shrunk to a manageable, desktop-sized package. This level of integration and miniaturization of fabrication technologies is our specialty as a startup.

3D Printed Electronics will not be a mass manufacturing technology

There have been exciting developments where electronic circuits are embedded within the physical structure of a device rather than being a separate element. Milk caps that sense sour milk and turbine blades with integrated thermal sensors are just a few examples – what does this mean? At a scale of one unit, a proof of concept. To create a million, highly improbable. Additive manufacturing methods are a notoriously difficult way to produce millions of units at a reasonable price and quality. PCB Printing technology as they stand are still in the early stages of commercialization and unless costs drop dramatically, it’s primary use-case will be for rapid prototyping in industry and education.

High-value Bespoke Fashion and Medical Applications will be the Primary Use in 5 years

Electronics are being more widely adopted in fashion, an industry that can command high margins and yet has low-barriers to competitive entry. That being said, making smart clothing has become the industry focus, providing more value to an attached brand that is defensible. Smart jewelery is another high-value, bespoke area of fashion that has been slowly adopting electronics into their work – the line between wearables and high fashion has become blurred.

Another growing application for 3D Printed electronics could be the medical industry, an area that requires unique, custom fitted work and can provide patients with better care and the doctors with more data when electronics are integrated. Circuits that are foldable or have n-number of dimensions are useful in providing form fitted devices (like for prosthetics), or rather something that can pack more circuitry into a smaller space (like for Laparoscopy).

Between now and 5 years the 3D Printed Electronics industry has a bright future that will create real value for the World. Predicting the future correctly is no better than a coin-toss, but the desire of rapid fabrication of printed circuit boards is not going to disappear. Knowing that, we think that BotFactory and the industry as a whole is going to crack this nut to provide frictionless inventiveness and creativity.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

There is more information about BotFactory here.

Featured image shows JF Brandon of BotFactory.