This edition of the Sliced 3D printing news digest offers the latest stories from across medical and dental, design, research and business.

Featured in this article: Torc2, Smartee Denti-Technology, CONICET, National University of La Plata, Duke University, Maya Varma, C3 Ventures, Michele Lizzit’s $12 3D printer, the Instagif camera, Mini, USC Viterbi, the University of Southampton, German RepRap, the University of Wisconsin-Madison, Dreve, Prodways and Matsuura Machinery.

Millions of dollars invested in 3D printed aligners, and the latest device innovations

UK medical device firm Torc2 has developed a “world first” 3D printer material that can be reshaped at temperatures safe to human skin.

In China, Smartee Denti-Technology has raised the equivalent of around $7.6 million (50 million yuan) contributing to the development of its 3D printed teeth retainer business.

In a similar approach to the Revotek-T Series of 3D bioprinters, researchers at Argentina’s National Scientific and Technical Research Council CONICET and the National University of La Plata have developed a 4-axis 3D printer for making tubular tissue models.

CONICET and National University of La Plata’s 4 axis 3D bioprinter. Clip via Sergio Katz on YouTube

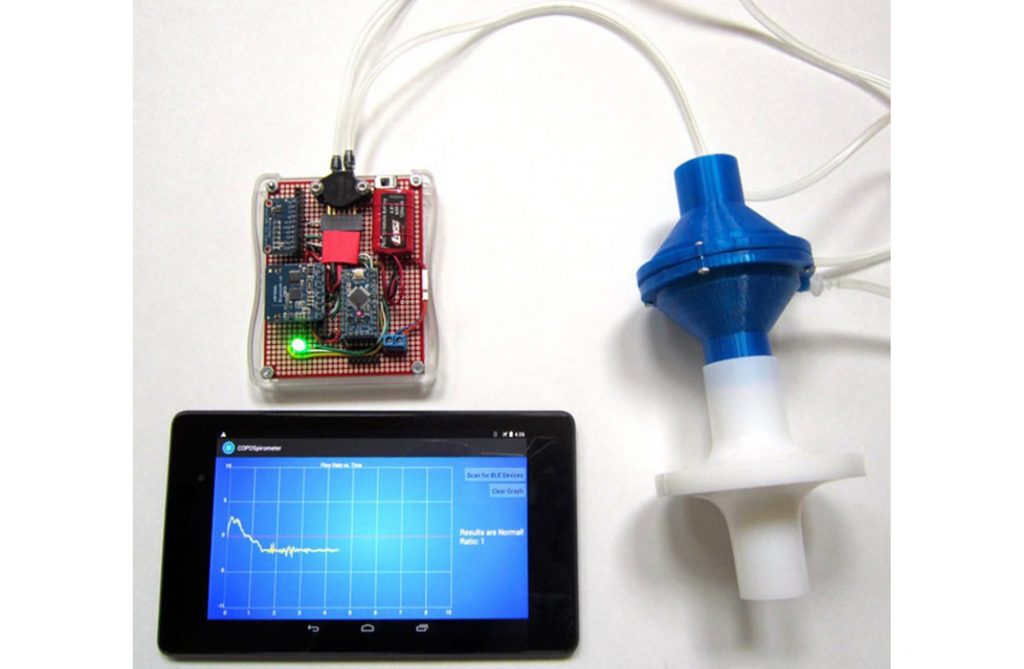

A lab-on-a-chip diagnostic device, called the D4 assay, developed at Duke University, NC, has been made using inkjet 3D printing technology and 17-year-old inventor Maya Varma has used the FDM technique to make parts for her lung disease detection system.

In another feel-good story, Missouri’s C3 Ventures 3D printed a wheelchair for a paralyzed cat. The black-and-white kitten, called Earl, now joins the ranks of other animals such as Zeus the whippet and EOS’ Mr. Cyrano L. Catte II that have had their lives changed by 3D printing.

Innovation on a mini scale

In a DIY maker project 18 year old Michele Lizzit, a student at Scientific High School “N. Copernico” – Udine, Italy, has built a $12 3D printer from parts of a dismantled scanner and paper inkjet printers. A video and further details of the innovative closed loop system can be found on Lizzit’s project website here.

Using a 3D Systems ProJet 7000 SLA 3D printer, designer and tech tinkerer Abhishek Singh has made the “Instagif NextStep” camera. Powered by Raspberry Pie, the camera is capable of producing moving snapshots, or gifs, the likes of which have only been seen before in the world of witchcraft and wizardry.

“Instagif – A DIY Camera that prints GIFs instantly” Clip via Abhishek Singh on YouTube

3D printing is also applied in the latest Mini Electric Concept, to create more efficient and aerodynamic wheels.

Fiber optic lobsters

Lobsters have inspired recent research into the reinforcement of medical implants and body armor. Yong Chen, co-author of the University of Southern California (USC) Viterbi study, explains, “When you just add nanofibers to plastic, overall you get 4x improvement in strength.”

“And if we add and then align the same nanofibers with a 1000-volt electric field, you get 8x improvement in strength.”

A full paper on the study is published in the journal Advanced Materials.

Angeles Camacho Rosales at the University of Southampton is investigating ways to make optical fibers, for internet transmission and more, using 3D printed glass. Speaking to Mexico’s National Council of Science and Technology (CONACYT), Rosales explains,

“Currently, when an optical fiber is designed, it often remains only as a prototype or computer simulation because in certain cases it is very difficult or even impossible to produce those designs, with this new method, these exceptional designs could be realized, transforming telecommunications as we know it.” (Translated from original).

After installing the first 3D printer on the ISS, U.S. off-world technology initiative Made In Space has similarly turned its efforts to the fabrication of fiber optics, believing that low gravity conditions may help the process.

Business updates: German RepRap, U.S. DoE, Prodways and Matsuura Machinery

In Series B financing, FFF 3D printer manufacturer German RepRap has raised an undisclosed seven digit figure of private equity.

The University of Wisconsin-Madison has received $2.1 million funding from the U. S. government to develop 3D printed heat exchangers for refrigerators. The money adds to an initial $2.85 million awarded to the team by the Department of Energy Advanced Research Projects Agency-Energy (ARPA-e) program in 2015.

German medical device company Dreve has solidified its commitment to 3D printing ordering its 13th MOVINGLIGHT dental 3D printer from Prodways.

And finally, Japan’s Matsuura Machinery will showcase the hybrid LUMEX additive manufacturing and CNC milling machine at September’s upcoming TCT show in Birmingham.

Never miss a story – sign up to the free 3D Printing Industry newsletter, and check out more news on Facebook and Twitter.

Register your research expertise on our 3D printing jobs site here.

Featured image: Sliced logo over Abhishek Singh’s Instagif camera. Original image via Abhishek Singh on YouTube