In this edition of Sliced, we feature: 3D Hubs, Prusa, Zortrax, Aurora Labs, Sintavia, EOS, German RepRap, Oberle, Lulzbot and Tomsk Polytechnic University.

3D Hubs releases its Q3 trends report

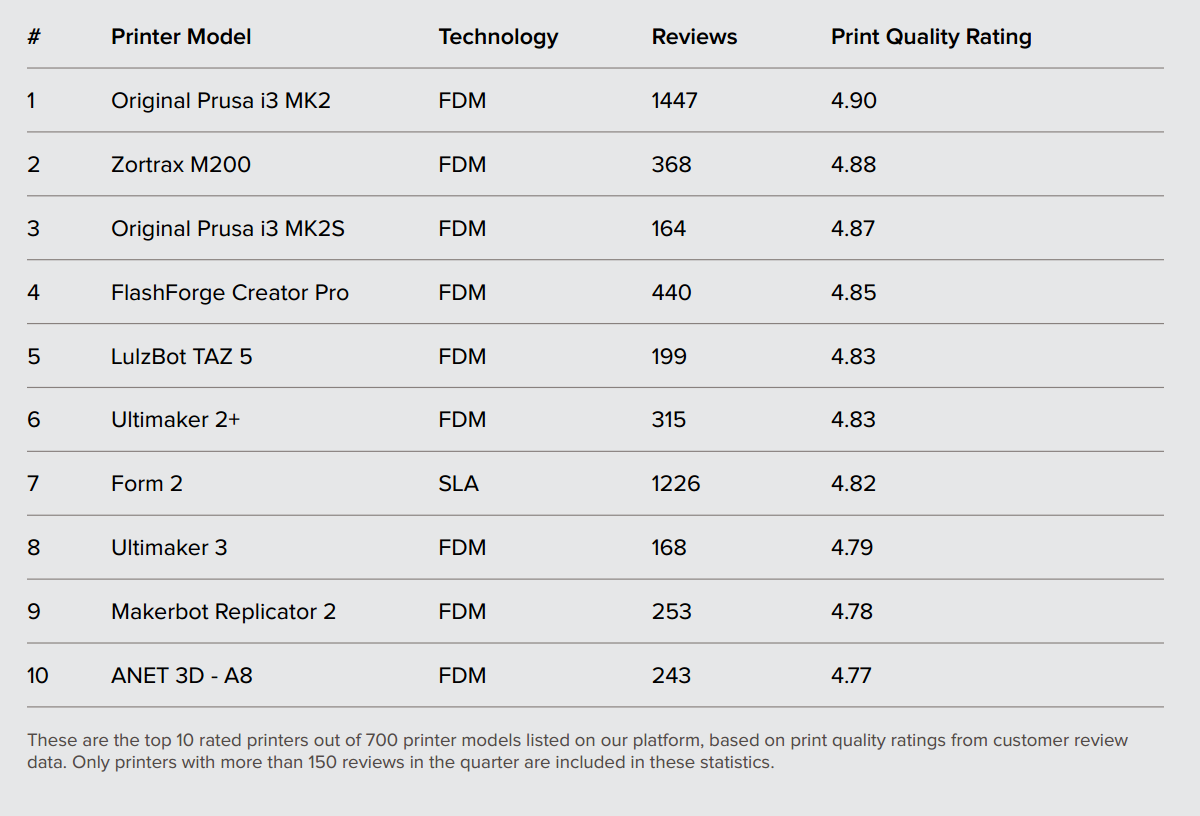

Online 3D printing platform 3D Hubs has released its trends report for Q3 2017. The group has changed the way it collects its data over previous reports. Now, printer ratings are based only on the previous quarter, the most used printers are now calculated, and online manufacturing platforms have now been included in the report.

In desktop 3D printing, the Original Prusa i3 MK2 maintains its no.1 spot as highest rated printer. While the Zortrax M200 has jumped into second from seventh position.

This should come as no surprise to readers of 3D Printing Industry as the Zortrax M200 was voted personal 3D printer of the year at the 3D Printing Industry Awards earlier this year.

Aurora Labs’ Tough gets going

Since going public last year, Australian 3D printing company Aurora Labs has lost its third Director. The latest, Samantha Tough has left to concentrate on a new role as a director at the Clean Energy Finance Corporation.

Lulzbot publish new case study

Cascade Lacrosse has used a Lulzbot 3D printer to make a helmet.

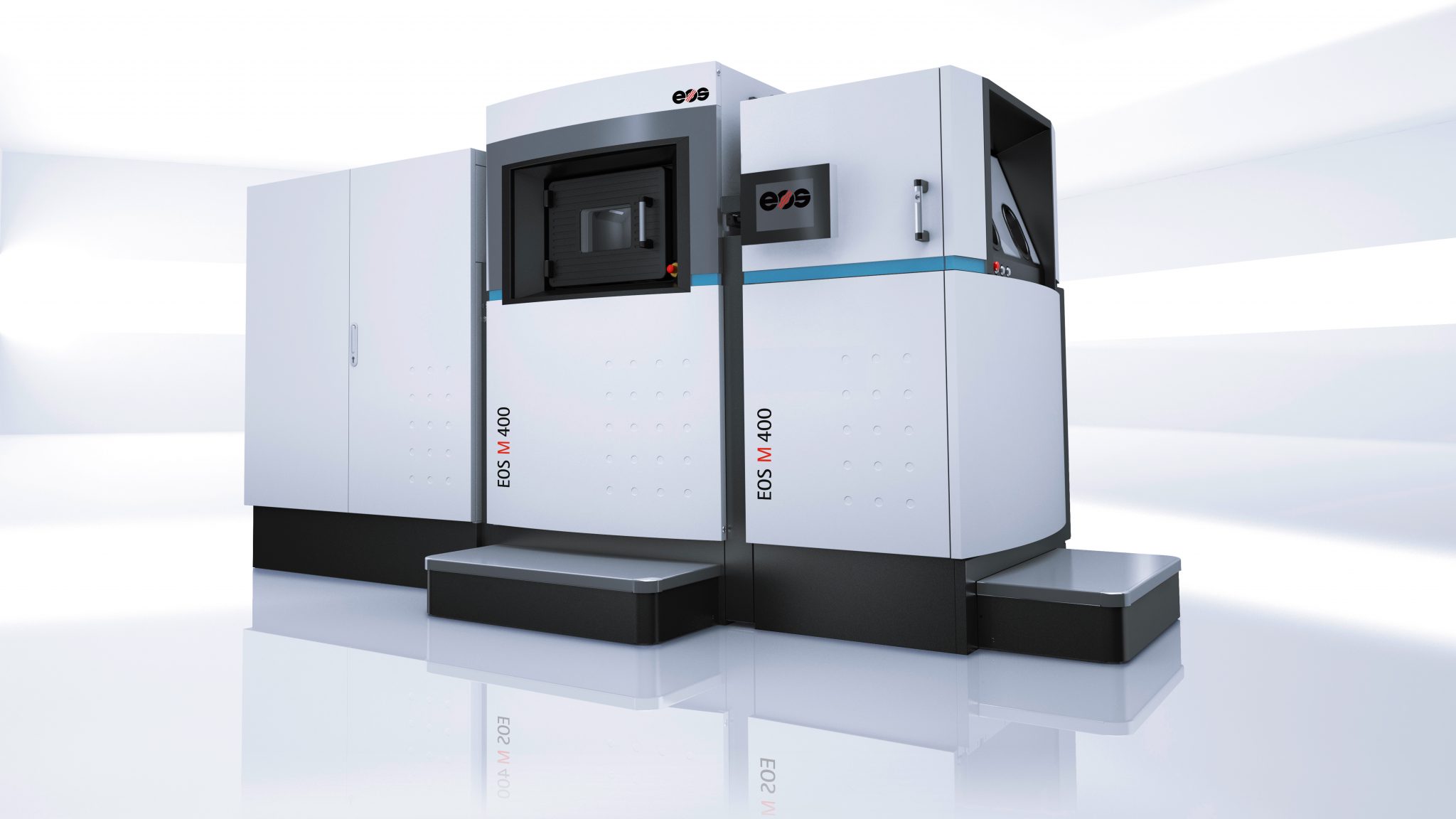

Sintavia adds large-scale EOS metal machine

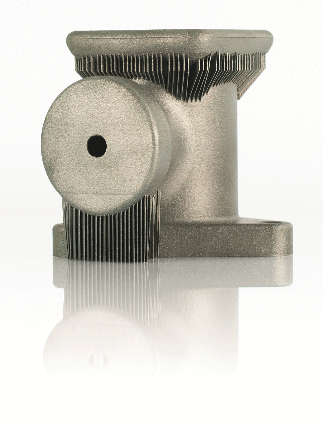

Florida-based metal additive manufacturing bureau Sintavia has announced its acquisition of a EOS M400 metal 3D printer. The machine is capable of printing large metal parts with a build volume of 400mm x 400mm x 400mm.

Sintavia will look to purchase several more machines as it expands with a new facility in Hollywood, Florida. According to the company, it expects to add 35 new machines with the majority being a similar size to the M400.

Doug Hedges, Sintavia’s President and COO, explains the purchase, “We believe it is among the most qualifiable of the large laser platform printers due to its well-controlled mechanical parameters and reliability. We have spent a great deal of effort developing processes for dependable results and to qualify the production of metal parts for OEMs. This system is a big step in the right direction for those efforts, particularly with respect to our defense and space customers.”

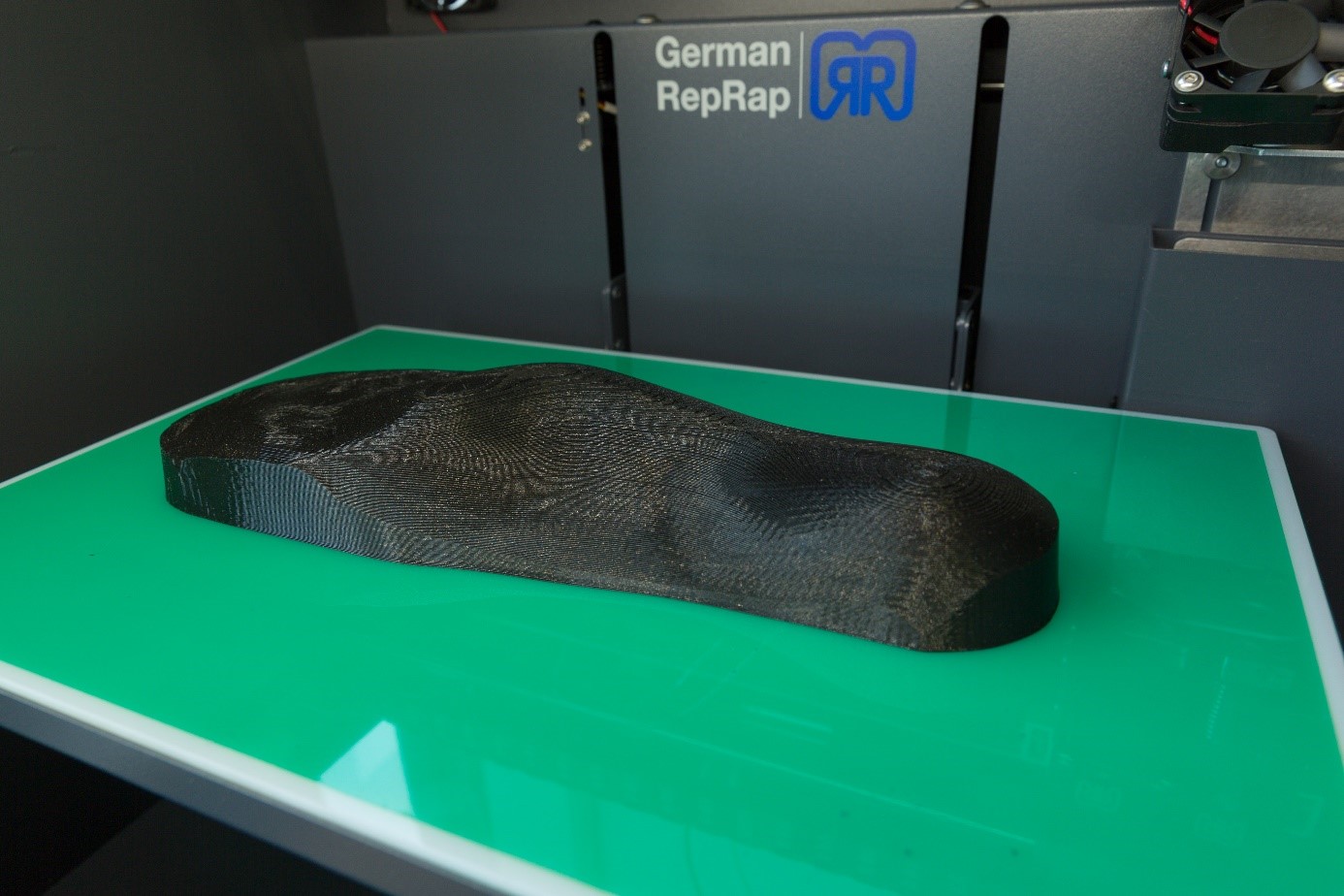

German RepRap helps German shoe company

German footwear company Oberle has shared details of its use of a German RepRap X350pro 3D printer. General Manager, Achim Oberle explains the company has always been “deeply committed to the most current methods and state-of-the-art technology.”

The manufacturer began specializing in custom ‘healthy shoes’ in 2006 and so required taking measurements of customers’ feet. However, Oberle was allergic to the foam used to create a positive mold in the traditional process so turned to making wood positive molds. This was enabled by the acquisition of a 3D scanner.

Despite this, the wood mold making process was lengthy and required external contractors. This finally led Oberle to implement the X350pro 3D printer into the process and is notably happy with the results,

“The 3D printer often runs throughout the night, and we’re considering the purchase of a second machine to manage our increasing order volume.”

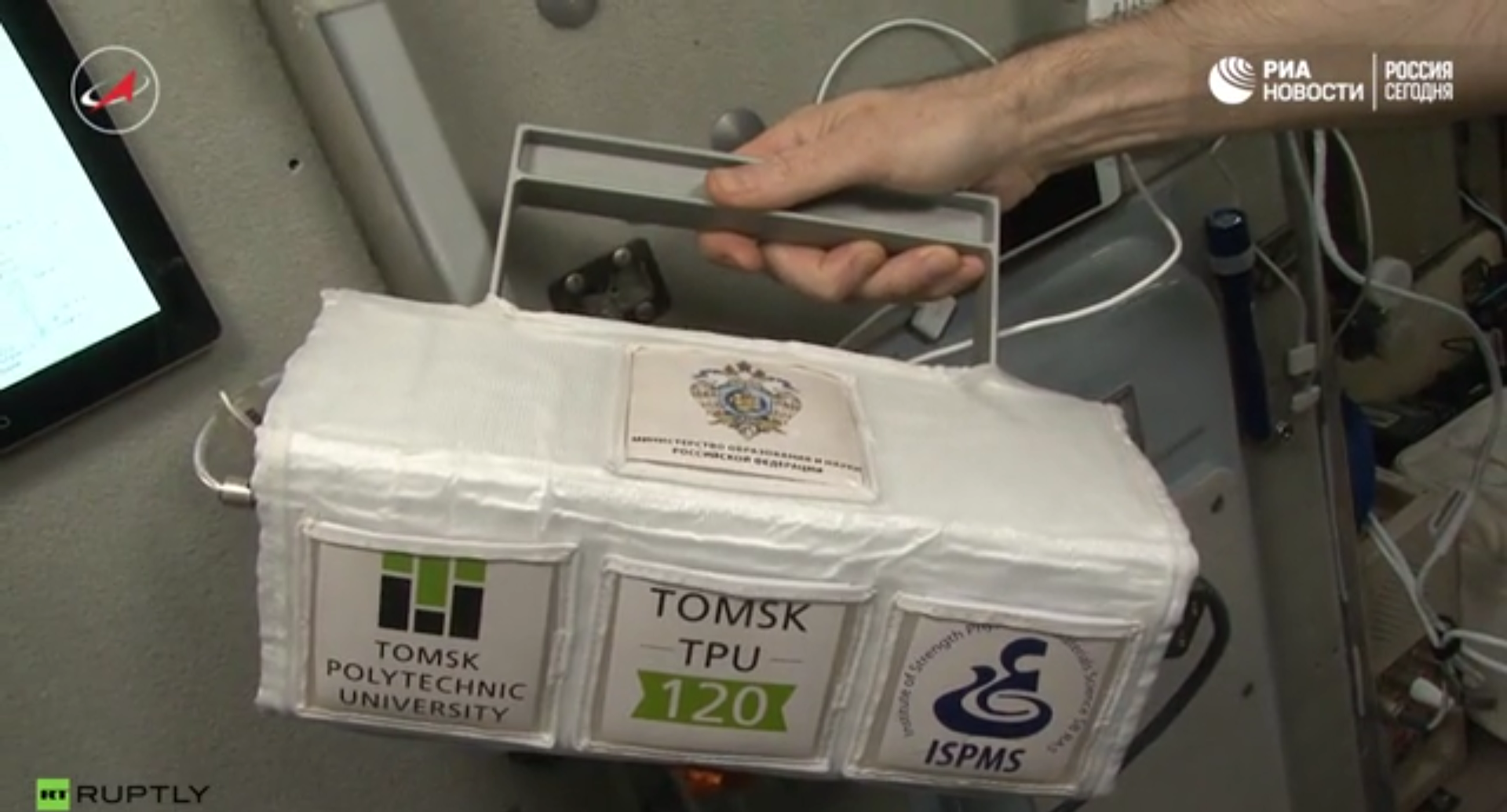

Russians to deploy 3D printed satellite

The Russian crew aboard the International Space Station will soon deploy a 3D printed microsatellite.

The Tomsk-TPU-120 microsatellite is set to be launched on 17 August having been sent to the ISS back in April 2016. The satellite was designed and manufactured by Tomsk Polytechnic University in Russia.

British heat treating company launches 3D printing technology

Bodycote, a leading manufacturer of heat treatment and thermal processing services has announced a new 3D printing manufacturing process.

Known as Bodycote Powdermet, the technology relies upon both 3D printing and well-established near net shape manufacturing techniques.

Stephen Harris, Group Chief Executive, explains “the recent breakthroughs are truly game changing technologies for component design and manufacturing. Industry applications are wide ranging with early adoption expected in aerospace, oil and gas, power generation and mining”.

The new technology promises higher structural integrity of parts and eliminates the need for welding together multiple components.

If you would like to pursue a career in additive manufacturing, take a look at our 3D printing jobs. And be sure to check out all the latest 3D printing events.

Subscribe to the 3D Printing Industry newsletter to stay up to date with all the latest 3D printing research news, follow us on twitter and like us on Facebook.

Featured image shows American, Japanese, and Russian astronauts aboard the ISS. Image via esmir.stoplusjednicka.cz