As we reported, Princeton researchers have “embedded tiny light-emitting diodes into a standard contact lens, allowing the device to project beams of colored light.” A few more details have come to light after a recent article was published in News at Princeton.

Lead researcher Michael Alpine cautioned that the lens is not designed for actual use. Why? Well, one reason might be that it requires an external power supply. He said the team created the device as more of a demonstration of the ability to “3D print” electronics into complex shapes and materials.

“This shows that we can use 3D printing to create complex electronics including semiconductors,” said McAlpine, an assistant professor of mechanical and aerospace engineering. “We were able to 3D print an entire device, in this case an LED.”

The hard contact lens is made of plastic. The researchers used tiny crystals, called quantum dots, to create the LEDs that generated the colored light. Different size dots can be used to generate various colors.

“We used the quantum dots [also known as nanoparticles] as an ink,” McAlpine said. We were able to generate two different colors, orange and green.”

The contact lens is also part of an ongoing effort to use 3D printing to “assemble

diverse, and often hard-to-combine, materials into functioning devices.” Recently, a team of Princeton professors including McAlpine also created a bionic ear out of living cells with an embedded antenna that could receive radio signals.

Yong Lin Kong was a researcher on both projects, and said the bionic ear presented analogous but different challenges.

“The main focus of the bionic ear project was to demonstrate the merger of electronics and biological materials,” said Kong, a graduate student in mechanical and aerospace engineering.

Conversely, Kong also said that the contact lens project involved the printing of active electronics using “diverse materials.” The materials were often “mechanically, chemically or thermally incompatible — for example, using heat to shape one material could inadvertently destroy another material in close proximity.”

The team not only had to reconcile and manage these incompatibilities, they also had to develop entirely new methods to print electronics, instead of using techniques commonly used in the electronics industry.

“For example, it is not trivial to pattern a thin and uniform coating of nanoparticles and polymers without the involvement of conventional microfabrication techniques, yet the thickness and uniformity of the printed films are two of the critical parameters that determine the performance and yield of the printed active device,” Kong said.

McAlpine said that one of 3D printing’s greatest strengths is its ability to create electronics in complex forms. Traditional electronics manufacturing builds circuits in flat assemblies and then stacks them into three dimensions. 3D printers can create vertical structures as easily as horizontal ones.

“In this case, we had a cube of LEDs,” he said. “Some of the wiring was vertical and some was horizontal.”

To conduct the research, the team built a new type of 3D printer that McAlpine

described as “somewhere between off-the-shelf and really fancy.” Dan Steingart an assistant professor of mechanical and aerospace engineering at the Andlinger Center, helped design and build the new printer, which McAlpine said cost around $20,000.

McAlpine said that he does not envision 3D printing replacing traditional manufacturing in electronics any time soon; instead, they are complementary technologies with very different strengths. “Manufacturers are using 3D printing, which is slow but easy to change and customize, to create molds and patterns for rapid prototyping.”

Prime uses for 3D printing are situations that demand flexibility and that require or are optimized by customization. As we’ve seen, conventional manufacturing techniques are not practical for medical devices that need to be fit to a patient’s particular shape or devices that require the blending of unusual materials in customized ways.

“Trying to print a cellphone is probably not the way to go,” McAlpine said. “It is customization that gives the power to 3D printing.”

In this case, the researchers were able to custom 3D print electronics on a contact lens by first scanning the lens, and feeding the geometric information back into the printer. This allowed for conformal 3D printing of an LED on the contact lens.

Besides McAlpine, Kong, Tamargo, Kim, Rand and Steingart, the Princeton researchers involved in the project included postdoctoral researchers Blake Johnson, Maneesh Gupta and Tae-Wook Koh, and graduate student Huai-An Chin. The Air Force Office of Scientific Research and the Defense Advanced Research Projects Agency (DARPA), which we didn’t previously report, provided support for the project. No specific details about the type or amount of support were available.

Source: Princeton University

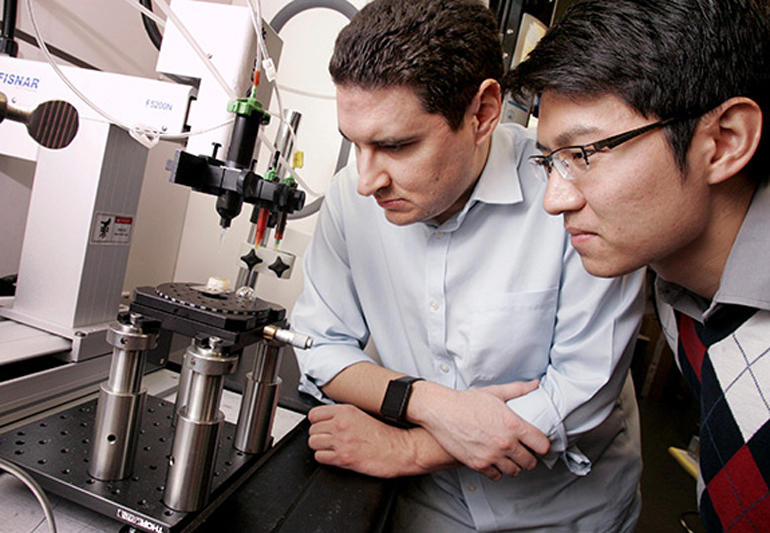

Photo Credit: Frank Wojciechowski, Princeton University