The month of May yielded a number of important events in the 3D printing industry, including the Additive Manufacturing Users Group (AMUG) 2021 event, major acquisitions from the likes of 3D Systems and CELLINK, and Desktop Metal launching a new wood 3D printing technology. The aerospace sector was also active with additive manufacturing milestones from GKN and Aerojet Rocketdyne.

AMUG 2021: May 2 – 6, 2021

May of 2021 kicked off with the Additive Manufacturing Users Group (AMUG) Conference, which ran from the 2nd to the 6th in Orlando, Florida. The event was the first major in-person 3D printing trade show held since the start of the COVID-19 pandemic, drawing in approximately 100 exhibitors and over 800 attendees.

Besides the exhibitions, the conference included technical presentations, panel discussions, a technical competition, evening gatherings, and general networking.

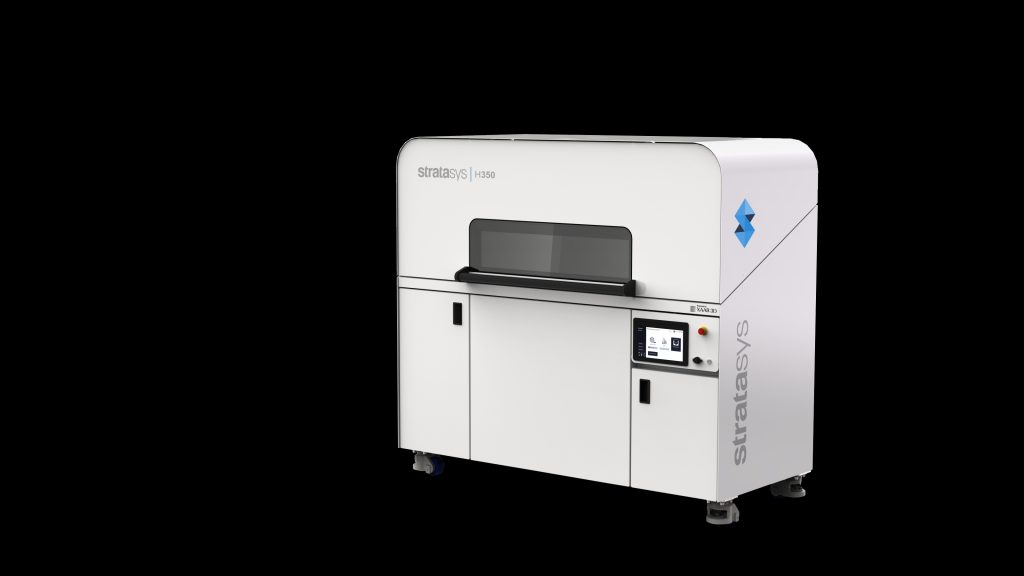

Looking at some of the more notable announcements made around AMUG week, Stratasys announced three new printers: the Origin One, the SAF H350, and the F770. Similarly, Essentium also announced the launch of its first independent dual extrusion (IDEX) 3D printer – the HSE 280i HT.

Acquisitions from 3D Systems and CELLINK

In business news, US-based 3D printer manufacturer 3D Systems announced two new strategic growth acquisitions for its 3D printing business. The companies in question were Allevi, a Pennsylvania-based 3D bioprinter developer, and Additive Works, a German 3D printing software developer. Made as part of the company’s aggressive four-step growth initiative, the two moves were intended to support 3D Systems’ regenerative medicine and industrialization efforts respectively.

Dr. Jeffrey Graves, President and CEO of 3D Systems, stated, “We continue to deliver on our four-phase plan with an increasing focus on investing for accelerated growth and profitability. I’m excited by the expertise, capabilities and technologies we are adding to the 3D Systems portfolio with Allevi and Additive Works.”

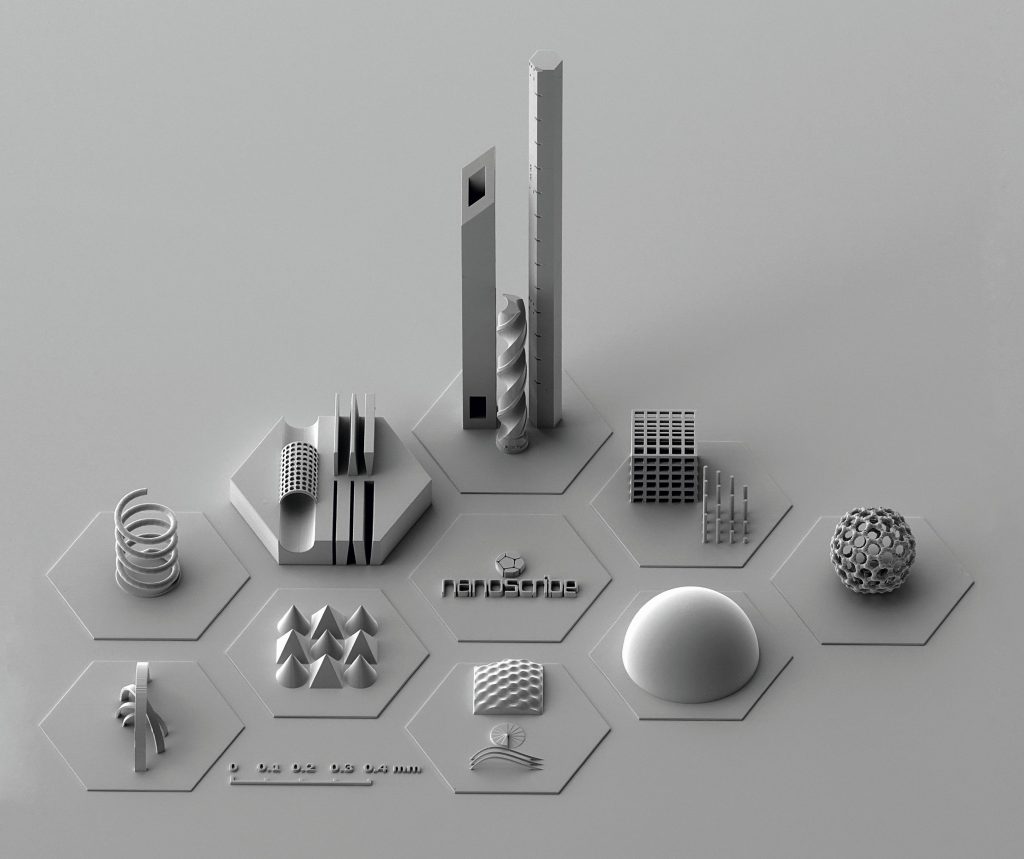

Swedish 3D bioprinter manufacturer CELLINK, now a part of the BICO Group, also announced the acquisition of two-photon polymerization (2PP) 3D printer manufacturer Nanoscribe. Through the deal, worth a total of €50 million, CELLINK took full control of Nanoscribe to integrate 2PP technology into its own capabilities, enabling the fabrication of more lifelike soft tissues.

“With Nanoscribe’s state of the art 2PP technology, we will complement our product portfolio and offer a wider range of products to our amazing customers,” said Erik Gatenholm, CEO of CELLINK. “We are combining our strong, purpose-driven growth agenda with trailblazing bioconverging technologies for the sake of improving health all around the world.”

Desktop Metal’s wood 3D printing technology

When it came to new technologies, industrial 3D printer OEM Desktop Metal stole the show with the launch of its subsidiary Forust, a brand focused on 3D printing functional end-use wood parts via binder jetting.

The Forust process works by upscaling waste byproducts from the wood manufacturing and paper industries (sawdust and lignin). By mixing these byproducts with a special bio-epoxy resin composite, the company can create sustainable 3D printing materials compatible with Desktop Metal’s binder jet technology.

William McDonough, a renowned architect and leader in sustainable development, stated, “The Forust technology allows us to take something that was previously wood waste and re-materialize it into exquisitely beautiful and useful things. We are honoring the cellulose and lignin of the trees by rearticulating them into assets for present and future generations.”

Aerospace achievements from Aerojet Rocketdyne and GKN

On the aerospace front, propulsion system manufacturer Aerojet Rocketdyne announced that an upgraded version of its RL10 rocket engine had successfully passed NASA hot-fire testing procedures. During the trials, the company’s new RL10C-X upper-stage engine, featuring an additive manufactured injector and combustion chamber, demonstrated ignition and long-term durability within in-space simulations.

“Successfully completing this test series validates our approach to incorporating 3D printing technology into the RL10 program in order to reduce cost while maintaining the engine’s unmatched performance,” said Eileen P. Drake, CEO of Aerojet Rocketdyne. “The RL10 has been a workhorse in the industry for nearly six decades and the RL10C-X will help ensure the engine maintains this leadership position.”

Elsewhere, aerospace supplier GKN Aerospace successfully manufactured a 3D printed intermediate compressor case (ICC) for aircraft engine manufacturer Rolls-Royce. The ICC was set to be used in a demonstrator program for Rolls-Royce’s upcoming UltraFan engine, and was developed as part of Clean Sky 2, Europe’s largest aeronautics research program focused on reducing the CO2 emissions and noise levels of today’s aircraft engines.

Henrik Runnemalm, Vice President of GKN Aerospace’s Global Technology Centre in Sweden, said, “The delivery of the UltraFan engine ICC to Rolls-Royce is a true milestone. It reaffirms the success of the Clean Sky 2 collaboration programme and we are excited to have implemented our latest sustainable technologies in the ICC’s development.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows wood products 3D printed by Forust. Photo via Forust.