Developments in the medical sector dominated 3D printing news in August 2023. Throughout the month, 3D Printing Industry reported on a number of advancements which leverage additive manufacturing to treat long-term health conditions.

All the 3D Printing News from 2023

Elsewhere, fervent acquisition and merger activity continued into August, whilst several companies demonstrated the sustainability benefits offered by 3D printing. Formnext + PM South China 2023 concluded August with a showcase of emerging additive manufacturing innovations.

Read on for key August 2023 3D printing news highlights from Apple, Triastek, 3D Systems, Stratasys, Desktop Metal, Xerox, ADDiTEC, Manufactura, Farsoon Technologies, Bright Laser Technologies, INTAMSYS, and more.

3D printing innovations in the medical sector

Leading 3D printer manufacturer 3D Systems continued its long-term regenerative medicine efforts in August by announcing a strategic partnership with biopharmaceutical firm Theradaptive.

Through this collaboration, the companies are integrating Theradaptive’s protein-engineering technology with 3D Systems’ 3D printed orthopedic implants. This will enable localized delivery of implants, optimizing healing outcomes for patients and signifying a notable step in the regenerative medicine space.

“Uniting these two world-class technologies promises to provide safer and more effective treatment options for patients who currently have few options,” commented Luis Alvarez, CEO and founder of Theradaptive. “This partnership sets the stage for many new products that will have the potential to significantly improve patient care.”

Chinese drug 3D printing firm Triastek announced the conclusion of the first First-in-Human (FIH) study of its 3D printed drug, dubbed T21. This drug is designed to treat moderate to severe ulcerative colitis. The tablets are produced using the company’s Melt Extrusion Deposition (MED) process. This allows for precise control of the drug’s release in the gastrointestinal tract.

Scientists from the University of Sydney and the Children’s Medical Research Institute (CMRI) collaborated to 3D print functional human tissues that mimic an organ’s architecture. Leveraging 3D photolithographic printing, the researchers utilized a combination of bioengineering and cell culture techniques to instruct stem cells to become specialized.

By generating microscopic mechanical and chemical signals, the scientists instructed the cells to form accurate organ-like structures. This technique was used to create a bone-fat assembly that resembles bone structure, and an assembly of tissues that resemble processes during early mammalian development.

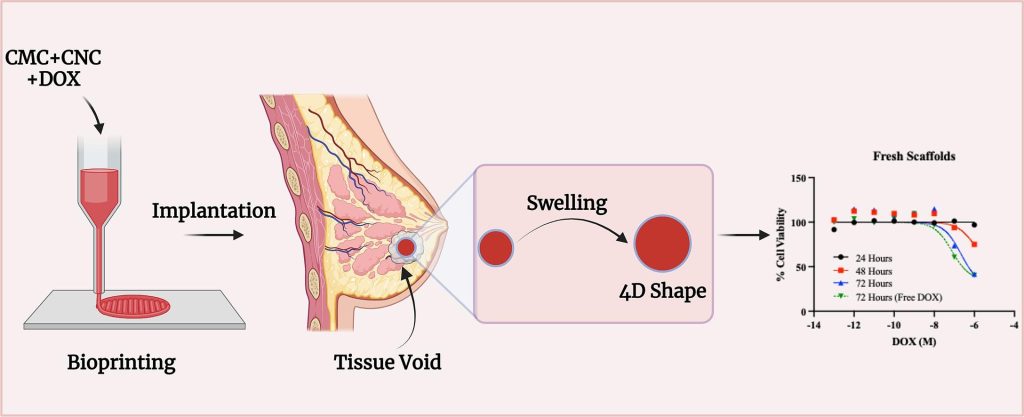

Elsewhere, researchers from Queen’s University Belfast developed 4D printed breast implants to treat breast cancer. This was said to be the first time 4D printing has been used to produce breast implants.

Thanks to the use of “smart materials” that can change morphology after 4D printing, these implants can be programmed to change size to better fit into a patient’s tissue cavity. Additionally, the 4D printed implants can release chemotherapy drugs directly at the point of need.

Merger and acquisition activity

Merger and acquisition developments again prevailed in the 3D printing news cycle. The saga between Stratasys, 3D Systems, Nano Dimension, and Desktop Metal continued into its fourth consecutive month in August.

Whilst it had been anticipated that a deal would be struck between 3D Systems and Stratasys, the publication of the two companies Q2 2023 financial results told a different story.

“While we had hoped to be in a position to announce a deal with Stratasys today, we’re not in a position to do so,” stated Dr. Jeffrey Graves, President and CEO of 3D Systems, during a call with investors. “Candidly, we expected this transaction to be announced by now and are frustrated by the pace and the lack of any engagement on the merger agreement.”

Moreover, Nano Dimension withdrew its plan to acquire Stratasys, leaving Desktop Metal as the only other player in this multi-company struggle. Towards the end of the month, the Stratasys and Desktop Metal merger seemed closer to fruition, as a date was set for a “Desktop Metal special meeting.”

Scheduled for September 28, the meeting would bring together Stratasys shareholders to vote on the proposed combination of the two companies. Read the September edition of our 2023 review of the year series to learn the outcome of this vote.

Elsewhere, Global print and digital document corporation Xerox sold its additive manufacturing business unit, Elem Additive Solutions, to US-based metal additive manufacturing company ADDiTEC. The decision to relinquish its 3D printing capabilities came as the company looked to refocus its strategic priorities and investments on its core print, IT and digital services.

Sustainability and 3D printing

Sustainability was one of the key buzzwords in 2023, and August saw its fair share of sustainability 3D printing news.

Global trade group Additive Manufacturer Green Trade Association (AMGTA) announced the preliminary results of a metal 3D printing life-cycle analysis (LCA). This study highlighted that binder jetting reduces carbon emissions by 38%, when compared to traditional metal casting techniques.

The LCA was conducted by the Yale School of the Environment(YSE) in collaboration with 3D printer manufacturer Desktop Metal. The production of a steel scroll chiller using an HVAC system from Trane Technologies was used to evaluate the environmental impact of binder jet 3D printing. According to the study, the significant reduction in greenhouse gas emissions was driven by reduced energy demand during the production phase.

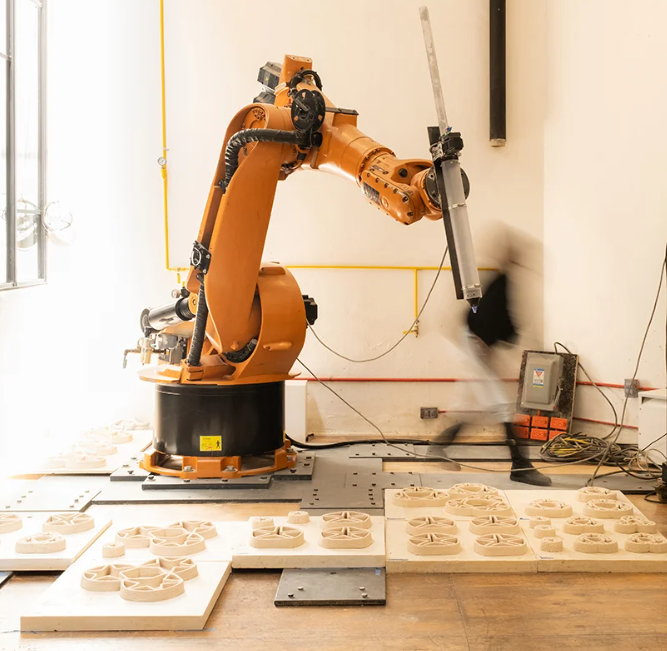

Mexico-based Manufactura partnered with furniture manufacturing and design workshop La Metropolitana to 3D print sustainable structures using recycled wood. The initiative, titled “The Wood Project” or “UN PROYECTO DE MADERA,” utilizes La Metropolitana’s daily production of 5-6 bags of sawdust, weighing 40 kg each.

Employing an extruder mounted on a KUKA KR-150 industrial robotic arm, the team 3D printed three architectonic-scale partition wall test pieces. These pieces are reportedly easy to replicate and assemble, and can be sustainably produced in a circular manner with waste-sourced raw materials from La Metropolitana.

Elsewhere, researchers from the University of Tokyo presented a novel method of rapid 3D object fabrication. This unique 4D printing method self-folds temperature-sensitive material into complex 3D shapes. Unlike conventional 3D printing processes which often generate extensive waste materials, this process is reportedly waste-free. The researchers view fashion design as a key application of this new technology. Indeed, the fashion industry often grapples with material wastage, especially in the production of bespoke designs.

Formnext + PM South China 2023

In August, 3D Printing Industry traveled to Shenzhen to attend Formnext + PM South China 2023. This year’s event saw 275 companies showcase their manufacturing technology, a third of which were dedicated solely to 3D printing.

During the show, China-based binder jet 3D printer manufacturer EasyMFG drew a lot of attention by showcasing 3D printed smartwatch casings. 3D printed in 316L stainless steel using its binder jetting technology, the casings reportedly undergo 18-20% shrinkage after they have been sintered.

This showcase highlights growing interest in the use of additive manufacturing for serial and mass production of consumer goods. In August, a number of 3D printing news reports indicated that Global consumer electronics company Apple Inc. is leveraging metal 3D printers from Farsoon Technologies and Bright Laser Technologies to produce key components for its smartwatches.

Similarly, the show saw Farsoon demonstrate key tooling applications for the injection molding sector. In fact, 80% of vape pens/e-cigarettes in China are now produced using 3D printed molds.

In the materials space, Formnext + PM South China saw Kexcelled unveil its new high-speed filament. Designed and tested for Bambu Labs’ 3D printers, this filament can reportedly operate at up to 500 mm/s.

Elsewhere, SoonSer unveiled its large-format Mars Pro 600 SLA 3D printer, whilst Kings 3D Printing reported the sale of over 10,000 3D printers. Shanghai-based INTAMSYS reported that it had sold over 1,000 units of its Funmat Pro 310 FDM 3D printer, with sales boosted by the China tech education sector.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Shenzhen World Exhibition and Convention Center, where Formnext + PM South China was held. Photo by Michael Petch.