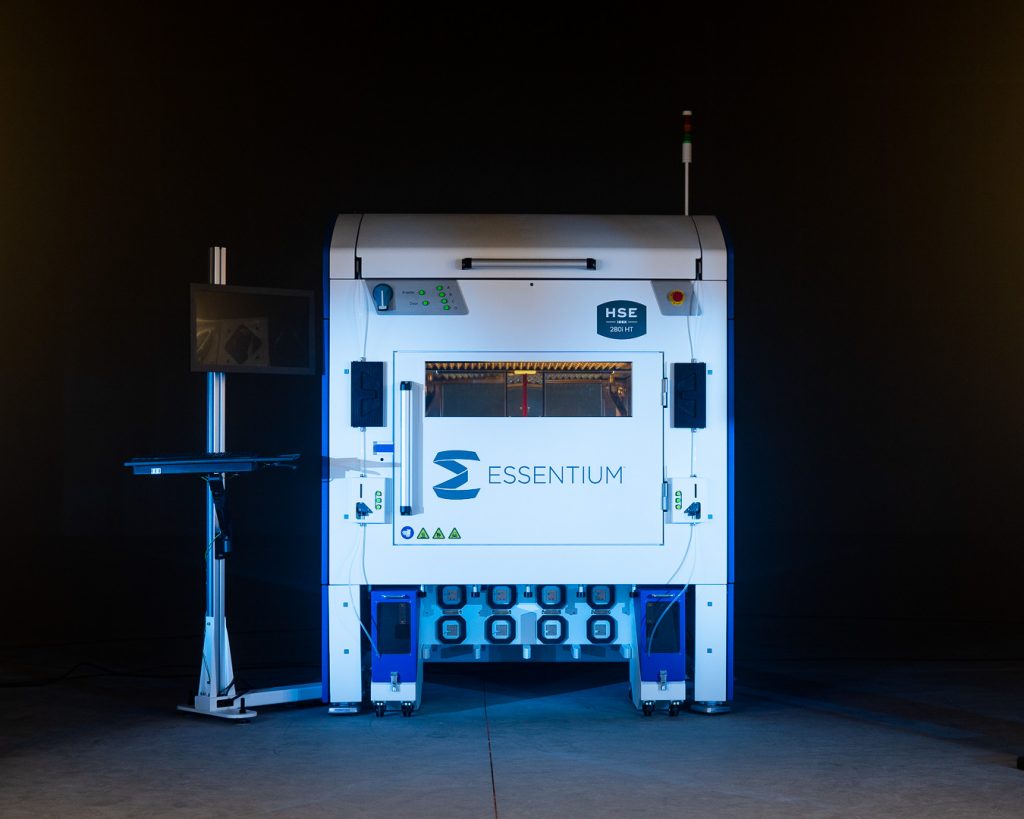

Industrial 3D printer manufacturer Essentium has launched its new High Speed Extrusion (HSE) 280i HT 3D printer.

Designed for the shop floor, the independent dual extrusion (IDEX) FFF system is characterized by its large build volume, high-throughput production capabilities, and high-temperature material compatibility. Aimed at high-volume manufacturers in sectors such as aerospace, electronics, automotive, and consumer goods, the HSE 280i HT is suitable for both functional prototyping and full-scale production using high-performance engineering filaments.

Blake Teipel, CEO of Essentium, states, “The manufacturing industry is increasingly moving toward a leaner and more agile future enabled by AM. This is the beginning of radical change, where billions will be saved through new economic and production models. But this change requires continuous and unrelenting innovation to be able to do things not done before, to make parts that haven’t been made before – and manufacture things that haven’t been manufactured before.”

High Speed Extrusion with Essentium

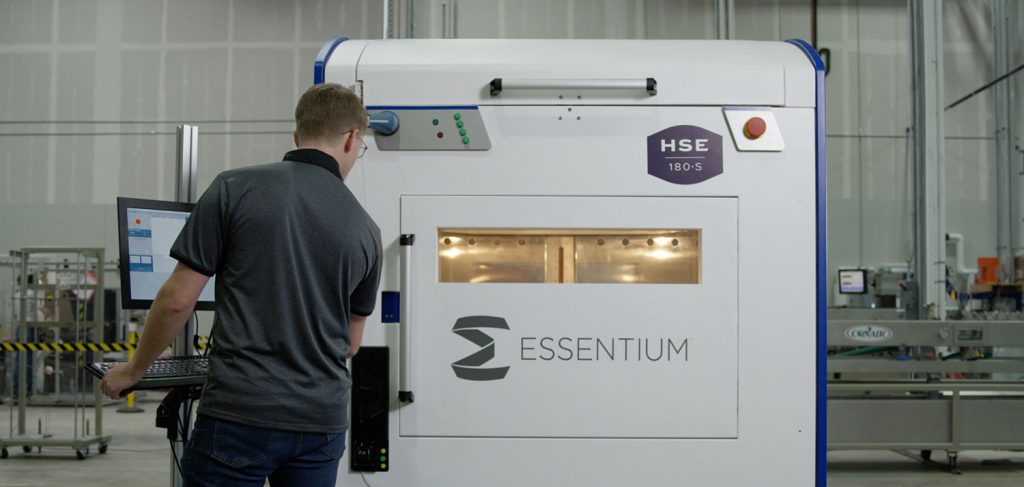

Essentium’s 3D printer portfolio, now two-strong, also includes the original HSE 180-S system. Available in three different versions, the 180-S is also aimed at manufacturers seeking high-volume polymer and composite production. Sporting a build volume measuring 690 x 500 x 600mm, the machine is well-suited for everything from high-strength jigs and fixtures to prosthetic sockets and orthotic devices.

2019 is really when the company started scaling the production of its HSE platform in response to growing demand, partnering with key industry players such as chemical company BASF and software developer Materialise.

The HSE 280i HT 3D printer

Essentium describes the HSE 280i HT as a ‘true IDEX’ 3D printer. Where most IDEX systems have printheads that are independent in the X-axis but locked together in the Y-axis, the 280i HT is fully independent in both. As such, users are able to leverage five different build modes that come as standard with the 3D printer: single head mode, support mode, multi-process mode, copy mode, and independent mode.

Combined with print speeds of up to 500mm/s, the feature grants users the ability to 3D print multi-part builds at truly industrial speeds, regardless of the parts’ geometric complexities. Equipped with a non-slip, high torque extrusion system and linear servo motors, the printer reportedly delivers 5x – 15x the throughput of similar competitors.

Teipel adds, “This is the industry’s first true IDEX machine– we believe the HSE 280i HT 3D printer is a game-changer, giving manufacturers the ultimate machine tool to 3D print at scale.”

When it comes to build volume, the one-ton behemoth boasts an impressive 695 x 495 x 600mm. While most industrial FFF systems rely on a heated build chamber, Essentium’s latest machine uses a multimodal heating method designed to directly heat the part rather than the space around it, eliminating lengthy chamber heat-up times.

Finally, with a maximum nozzle temperature of 550ºC, the HSE 280i HT is being launched alongside Essentium’s new PP-CF filament – a 20% carbon fiber-reinforced polypropylene. Developed in partnership with LEHVOSS Group, the material offers excellent mechanical properties, chemical resistance, and a low surface energy, making it particularly useful for silicone and urethane molding applications.

Technical specifications and pricing

Below are the technical specifications for the Essentium HSE 280i HT 3D printer. The system is available to order now. Visit the Essentium store page to receive a quote.

| Build volume | Up to 695 x 495 x 600mm (mode dependent) |

| Print speed | 500mm/s |

| Printer dimensions | 1590 x 1350 x 2490mm |

| Nozzles | 2x Gen 5 Hozzle heated nozzles |

| Nozzle temperature | Up to 550°C |

| Nozzle diameter | 0.4, 0.8mm |

| Filament diameter | 1.75mm |

| Weight | 1000kg |

| Bed temperature | Up to 190°C |

| Chamber temperature | Up to 200°C |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Essentium HSE 280i HT. Photo via Essentium.