The 2021 Additive Manufacturing Users Group (AMUG) Conference convened May 2nd thru 6th in Orlando, Florida much to the relief and excitement of the organizing committee. Drawing in approximately 100 exhibitors, and more than 800 attendees, the event represents the first major in-person 3D printing event held since the world shut down 15 months ago. Although notably smaller than prior years due to continued travel restrictions for would-be international participants, this year’s program still exceeded expectations across all facets including the AMUGexpo, technical presentations, panel discussions, the technical competition, evening gatherings, and general networking.

With most of the industry’s signature exhibitors absent at the AMUGexpo, smaller companies took the opportunity to stand out the first two days and at various sponsored sessions that kept to the technical user spirit of the conference. In no particular order, here are the trends, companies, and announcements that 3D Printing Industry came across at the 2021 AMUG Conference. Hopefully, this overview helps ease that fear of missing out for those that couldn’t make it in person.

Open. Industrial. Production. Partnership. These words sum up some of the themes surrounding announcements and plans across materials, hardware, post-processing, and software.

High-strength metal alloys and open materials

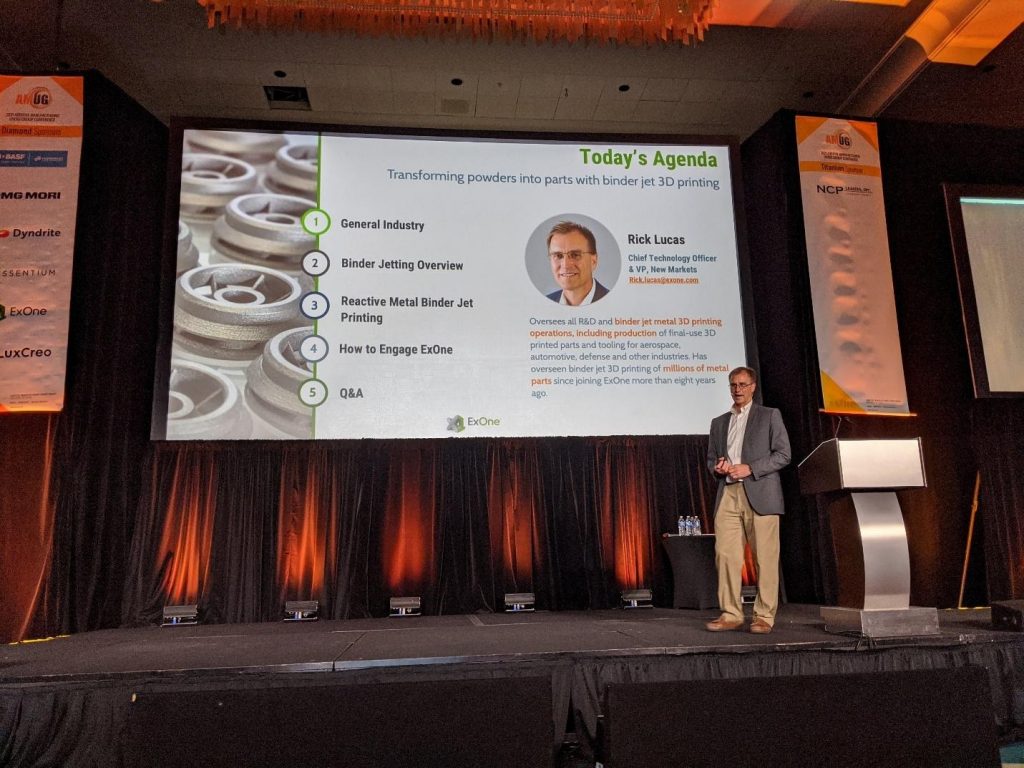

ExOne’s CTO and VP of New Markets, Rick Lucas, expanded on the recently announced 99% dense 6061 aluminum binder jetting material validated in partnership with Ford. Many consider the high-strength 6061 and 7075 aluminum alloys to be the final frontier for 3D printable materials; only time will tell if binder jetting will enable production applications from an economic perspective in addition to a technical perspective.

Also on the metals front, H.C. Starck’s R&D Application Engineer, Faith Oehlerking, showcased ongoing development and opportunities in refractory metals for laser powder bed fusion systems. Looking around the AMUGexpo highlighted one of the biggest sponsors of the event: BASF 3D Printing Solutions. 3D Printing Industry caught up with the Managing Director for North America, Jim Reddy, who commented on the company’s push towards open materials across technology categories and expects traditionally closed printer manufacturers will eventually benefit. He positioned the shift as a long-term necessity to take the industry further into production applications as the high-mix compliment to injection molding.

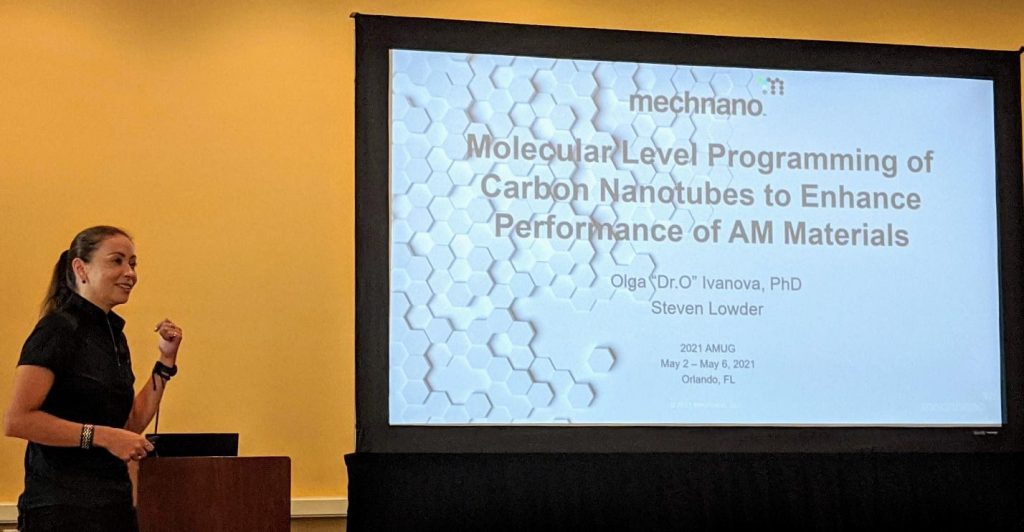

Across from BASF was the Essentium booth where a recently announced carbon fiber-filled polypropylene was on display. The commodity polymer is notoriously troublesome to print and becomes even more versatile as a CF-filled variety. Last on the materials announcements was Mechnano, an Arizona-based materials startup that recently came out of stealth mode with an electrostatically dissipative black photopolymer resin that was presented at one of the technical sessions. Claiming the conductivity benefits from fully dispersed surface-functionalized carbon nanotubes, the company plans to launch additional products in a number of material form factors for various printing processes. Although thermoplastic ESD materials have become rather common, opening up this attribute in photopolymer resins makes for an intriguing alternative for certain applications.

Hybrid AM systems, directed energy deposition, and high-speed sintering

In hardware, two groups mentioned “hybrid” capabilities at the show. DMG Mori displayed a multi-material die-cast mold with integrated cooling channels and a bronze core. Also on display was Titan Robotics’ Atlas-HS offering a near-net-shape pellet-fed polymer extrusion capability in combination with milling tool options. Both companies have historically offered additive manufacturing equipment based on CNC motion control platforms making a hybrid setup a logical offering to the market.

For those less familiar with directed energy deposition, a panel discussion with representatives from Norsk Titanium, Optomec, and Meltio provided an opportunity for attendees to learn about the materials and applications from three differentiated companies. There were newer names in hardware as well. Rapidia, a Canadian 3D printing company has a material extrusion process to produce metal parts that do not require a binder removal step prior to heat treatment. The exclusive partnership with ExOne brings the office-friendly Metal Designlab printer and furnace as a lower price point competitive offering.

Right across at the AMUGexpo was LuxCreo, a venture capital-backed DLP and LCD 3D printing entrant in the U.S. market that has decided to offer its materials, software, and cloud-connected printers for sale after years of development and service bureau operations in China. The direct-printed clear dental aligners using in-house developed materials and in some cases, own membrane technology, make for the same “solutions approach” that has propelled some of the industry’s leading brands to date. The company’s strong presence adds to the general excitement and recent M&A activity around photopolymer 3D printing.

Lastly, polymer extrusion giant Stratasys and Essentium both made notable hardware announcements in the week leading up to AMUG. Stratasys announced three printers: its Stratasys Origin One DLP offering as an open material platform, the SAF H350 printer in the high-speed sintering technology category, and the F770 FDM model for large prototyping applications. The DLP and HSS technologies represent a significant expansion for Stratasys’ competitiveness in certain production-focused applications and in the case of the One, a departure from its closed approach to materials. Essentium announced the first independent dual extruder (IDEX) polymer extrusion system called the HSE 280i HT. Claiming 5x to 15x the speed of competing printers and a production-oriented mindset with full IDEX capabilities available later this year, the HSE 280i HT sits at the opposite end of the spectrum from the Stratasys F770’s prototyping persona.

Accelerating activity in post-processing and support services

Apart from the materials and hardware announcements, post-processing continues to build momentum in an industry where it can often make up 50% or more of 3D printed part costs and production timeframes. DyeMansion’s partnership with Stratasys and PostProcess Technologies’ partnership with Carbon are two notable endorsements for specialized additive post-processing equipment companies looking to address just that challenge. However, what was striking at the AMUGexpo was seeing no fewer than 15 companies covering all aspects of post-processing from de-powdering and powder management to filtration, surface finishing, hot isostatic pressing, and other heat treatments. It isn’t clear whether this representation is skewed due to the smaller size of this year’s expo, but it is encouraging to see both specialized and generic post-processing companies taking additive manufacturing as a serious opportunity. The lack of standards or even recommendations for post-processing equipment by printer manufacturers certainly reinforces the presence of so many groups at an AM user conference.

Tying together the additive manufacturing workflow and the disparate data sets remains a difficult but necessary goal for quality, traceability, and operational management purposes, to name a few benefits. Seeing Link3D, 3YOURMIND, Authentise and 3D Control Systems all exhibiting was a healthy reminder that there is no single specialized MES, or manufacturing execution software, solution that addresses all aspects of the AM workflow. Adding in groups such as Hexagon, which has partnered with Authentise, and Link3D’s recently announced plan for acquisition by Materialise show that partnerships might be the best path forward. A 3D printing workflow and MES panel discussion reminded new and experienced attendees alike that despite the collective efforts of groups like 3YourMind, Link3D, Authentise, and Materialise, that Microsoft Excel is still the number one incumbent waiting to be displaced in the industry.

![[L-R] Shane Fox Link3D, Alex Donnadieu 3YOURMIND, Dave Flynn Materialise, Derek Ellis Authentise, Kevin Ayers as Moderator Danfoss. Photo by Dayton Horvath](https://3dprintingindustry.com/wp-content/uploads/2021/05/L-to-R-Shane-Fox-Link3D-Alex-Donnadieu-3YOURMIND-Dave-Flynn-Materialise-Derek-Ellis-Authentise-Kevin-Ayers-as-Moderator-Danfoss.-Photo-by-Dayton-Horvath-1024x682.jpg)

Another software partnership worth noting is between HP and Dyndrite that despite being announced late last year was notable in its demonstration of build preparation, slicing, and workflow automation via Python APIs. One final and unlikely software mention is from BASF. With dedicated engineers focused on performance in various applications, BASF’s Ultrasim simulation service offers a range of material and process-specific capabilities to improve customer success with its 3D printable materials.

Sharing technical knowledge

Taking a step back from the themes and trends, there were two outstanding presentations that 3D Printing Industry made it to that really stood out as exemplary to the AMUG spirit and to the impact AM is already having. The first presentation was from Dawn Lissy, President, and Co-Founder of Empirical Technologies Corp. Walking into the medical regulatory presentation with hardly any exposure to the topic, I walked out with a new appreciation and understanding for the intricacies, challenges, and involvement medical AM companies go through with the FDA approved, cleared, or authorized devices we often take for granted. Furthermore, the slides available to all attendees will undoubtedly serve as the starting point whenever one may need to revisit the topic. Education was clearly top of mind when this talk, like many others, was added to the AMUG schedule. The other presentation that stood out was Dr. Jonathan Morris’ keynote about Mayo Clinic’s progress from one 3D printer to taking over an entire hospital wing to support the hospital group as its own device manufacturer. When 3D printers are displacing CT scanners for floor space at the Mayo Clinic, it is a testament to the value provided by 3D printing for surgical planning, surgical guides, and patient consent. Dozens of examples throughout Dr. Morris’ presentation certainly solidified 3D printing’s role in providing a higher standard of care for some of the most challenging medical procedures yet attempted.

AMUG will often remind you that it is by users, for users. Having spent five days experiencing the AMUG Conference for the first time, I recognize that whenever this phrase is quoted, it really means that AMUG is about the entire additive manufacturing community striving to help each other with improving our global community. This event was a reminder that even after 15 difficult months, it is the community’s openness that will lead to partnerships and to success in industrial production, however you may define it.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Jim Reddy, Managing Director of BASF 3D Printing Solutions North America, showing a thermoplastic polyurethane lattice. Photo by Dayton Horvath.