The 3D Printing Industry Review of the Year continues.

By many measures, the biggest 3D printing news story in 2023 was M&A activity around several of the largest companies in the industry, including a rare 3D printing unicorn. As our detailed timeline of the takeover plans by Stratasys, Desktop Metal, 3D Systems and Nano Dimension shows, plans for consolidation began in 2021. However, the arrival of activist investor Murchinson and subsequent clash with Nano Dimension’s CEO made the previously behind the scenes battle for control front page news.

Away from M&A activity, February 2023 saw several updates around research projects and material developments. Elsewhere, Fabric8Labs concluded a $50M Series B investment round.

Read on for February 3D printing news from Nano Dimension, iFactory3D, IIT Bombay, IperionX, Sakuu, and more.

3D Systems, Desktop Metal, Stratasys and Nano Dimension takeover talks

In July 2022, Stratays modified their articles of association to enact what is commonly known as a poison pill defense to potential corporate takeovers. The filing of this shareholder Rights Plan sought to protect the company from an unwanted hostile takeover, following Nano Dimension’s purchase of a 12.1% stake in Stratasys.

The rationale for this activity would become more apparent in February 2023, as Murchinson Ltd., a relatively unknown activist fund, made public its plans to acquire Nano Dimension. At the time, Murchinson was the company’s largest shareholder, holding 5.1% of its outstanding shares. Nano Dimension was certainly an attractive target, due to accumulated cash on the balance sheet of $1 billion.

What began as a small-scale dispute, would soon snowball into a complex web pulling 3D Systems, Stratasys and Desktop Metal into an escalating battle to control a potentially monopolistic 3D printing behemoth.

The cash balance of Nano Dimension drew the attention of Murchinson, who sought to change the board and deploy the funds in an alternative manner. Nano Dimension had already spent some of the funds raised from multiple investment rounds to purchase over 12% of Stratasys’ outstanding shares, as well as NanoFabrica, Admatec/Formatec, Essemtec, Global Inkjet Systems, and DeepCube.

In an open letter to its fellow shareholders, Murchinson expressed its dissatisfaction with Nano Dimension CEO and chairman Yoav Stern’s leadership, describing it as “poor capital allocation and unfortunate corporate governance.”

Murchinson pointed to Nano Dimension’s share value as lagging behind ‘its only self-reported peer Stratasys by 27% over the past two years,’ with the firm’s stock trades at a ‘substantial rebate’ to the balance sheet. Murchison argued that this reflected market concern that Stern would continue to ‘destroy value.’

Over the course of 2023, and via frequent missives issued by the Stern, it became apparent that Nano Dimension had performed significant due diligence across the 3D printing sector, by some appraisals looking at over 100 potential acquisition targets. This strategic move was made to counteract the kind of attention Nano Dimension was receiving from Murchinson, setting the stage for the biggest 3D printing M&A saga of the year.

3D printing research initiatives

Research helps determine the viability of a particular technology before it is exposed to a larger audience. Keeping this in mind, Korea Electrotechnology Research Institute (KERI) and the Ulsan National Institute of Science and Technology (UNIST) researchers developed core technology for 3D printed smart contact lenses, with low-power monochrome displays showcasing augmented reality functionalities like live navigation.

Published in Advanced Science, this technology uses Prussian blue ink micro-patterns, promising cost-effective augmented reality devices. The Arduino Uno-controlled prototype showcases preset images and holds promise for real-time navigation by projecting GPS-based directions. Testing on living human eyes is the next step before potential commercialization.

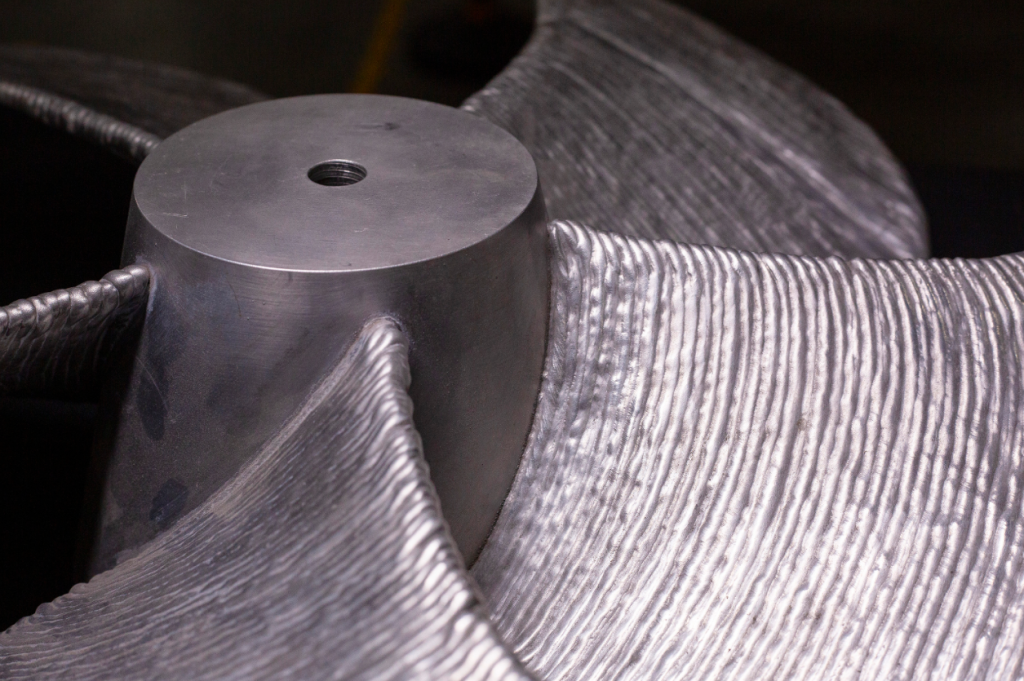

The Innovative Manufacturing Cooperative Research Center (IMCRC) and AML3D, successfully commercialized a high-strength aluminum wire feedstock for welding and 3D printing. Developed in collaboration with Deakin University, the wire requires only 30 minutes of thermal processing after printing.

AML3D aimed to reshape manufacturing processes, particularly in shipbuilding and aviation, addressing challenges associated with current aluminum alloys. Supported by IMCRC, the collaboration makes advancing metal part manufacturing more efficient and cost-effective, potentially boosting Australia’s competitiveness in the industry.

German start-up iFactory3D commissioned a thesis exploring the economic viability of 3D belt printers for serial production in manufacturing. The study compared iFactory3D’s One Pro 3D belt printer to traditional Cartesian FFF/FDM printers.

Findings revealed lower variable expenses for the 3D belt printer in all cases, with a significant reduction in manufacturing costs due to automation. The unrestrained length of the installation space and continuous production capabilities contributed to cost savings, making the 3D belt printer economically favorable for batch production in small to medium enterprises.

In other news, Dr. Pushkar Kamble, (Ph.D.) Institute Post-Doctoral Fellow, Rapid Manufacturing (RM) Lab, at IIT Bombay, provided insights on the ICE 3D printing research.

IIT Bombay’s proprietary ICE 3D printer’s Sub-Zero Additive Manufacturing (SZ-AM) process utilizes deionized water and glycerol solution to create ice objects at -30°C. The SZ-AM process involves simultaneous dispensing of material and support liquids, with controlled heating to avoid nozzle clogging. Ice components can be used as investment casting patterns, offering advantages over wax, as ice reduces support removal challenges.

Materials shaping the 3D printing industry

Materials play a pivotal role in the 3D printing sector. As a result, material launches have also been a focus in February. In alliance with Tethon3D, Mechnano developed a high-temperature, rigid electrostatic discharge (ESD) material, dubbed C-Lite resin, using Mechnano’s carbon nanotube technology (CNT).

C-Lite is designed for custom nano-uniform ESD parts enduring high-temperature wave soldering processes. The material enhances manufacturing agility, enabling quick-turn fabrication with ultra-high accuracy. Trilogy-Net‘s reflow tests confirmed C-Lite’s dimensional stability and durability after 50 cycles.

Uniformity Labs unveiled UniFuse AlSi10Mg Aluminum powder with advanced Laser Powder Bed Fusion (LPBF) printing parameters at 50um and 90um layer thickness. UniFuse AlSi10Mg demonstrates superior mechanical properties, surface finish, printing yield, and part reliability. Uniformity’s advancements enable a 75% faster build rate compared to competitors at the same layer thickness, showcasing additive manufacturing’s potential for industrial-scale production, says the company.

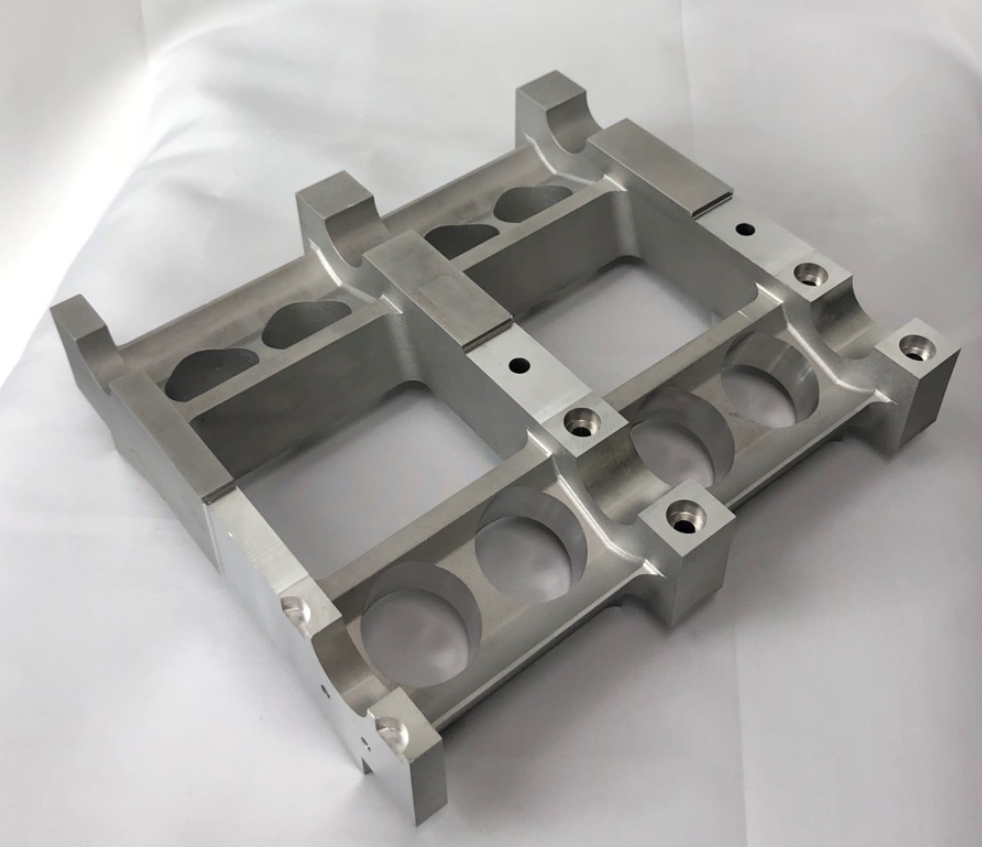

Elsewhere, 3D printer manufacturer Mantle Inc. highlighted successful implementations of its metal 3D printing technology at Nicolet Plastics and Westec Plastics. Both serving the medical device market, these injection molders utilized Mantle’s technology to streamline toolmaking processes.

Nicolet Plastics significantly reduced toolmaker time from 180 hours to 12.5 hours, achieving faster production of molded component samples. Westec Plastics adopted Mantle’s technology to generate 75-95% complete H13 inserts, cutting tooling costs and allowing toolmakers to focus on critical processes.

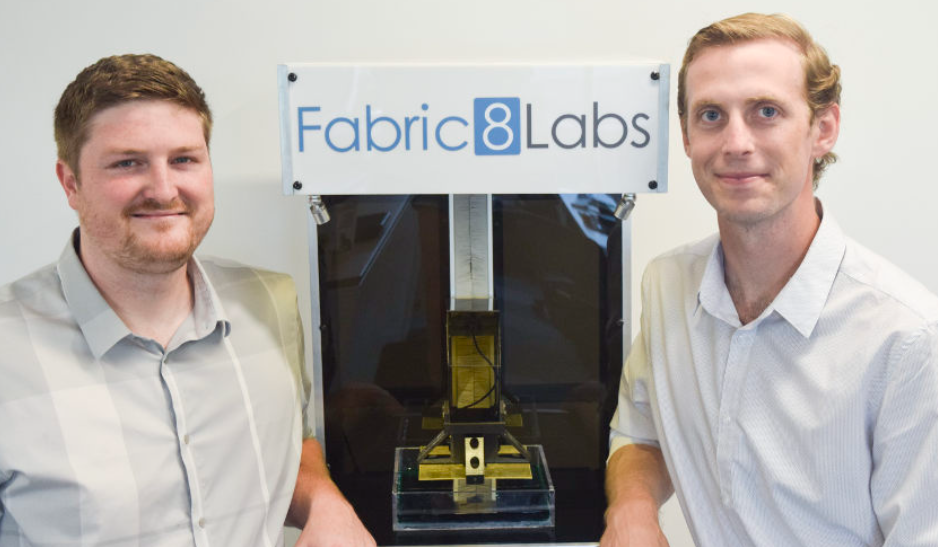

Fabric8Labs’ $50M Series B investment hits the headlines

Fabric8Labs secured $50 million in a Series B investment led by New Enterprise Associates (NEA), with participation from Intel Capital, imec.XPAND, and more.

Fabric8Labs aimed to use the funding to expand the company’s Electrochemical Additive Manufacturing (ECAM) technology and establish a pilot production facility. The technology is aimed at resolving challenges in power density, thermal management, and sustainability across various applications, says the company.

2023: 3D Printing Industry review of trends and news.

2022: 3D Printing Industry review of trends and news.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

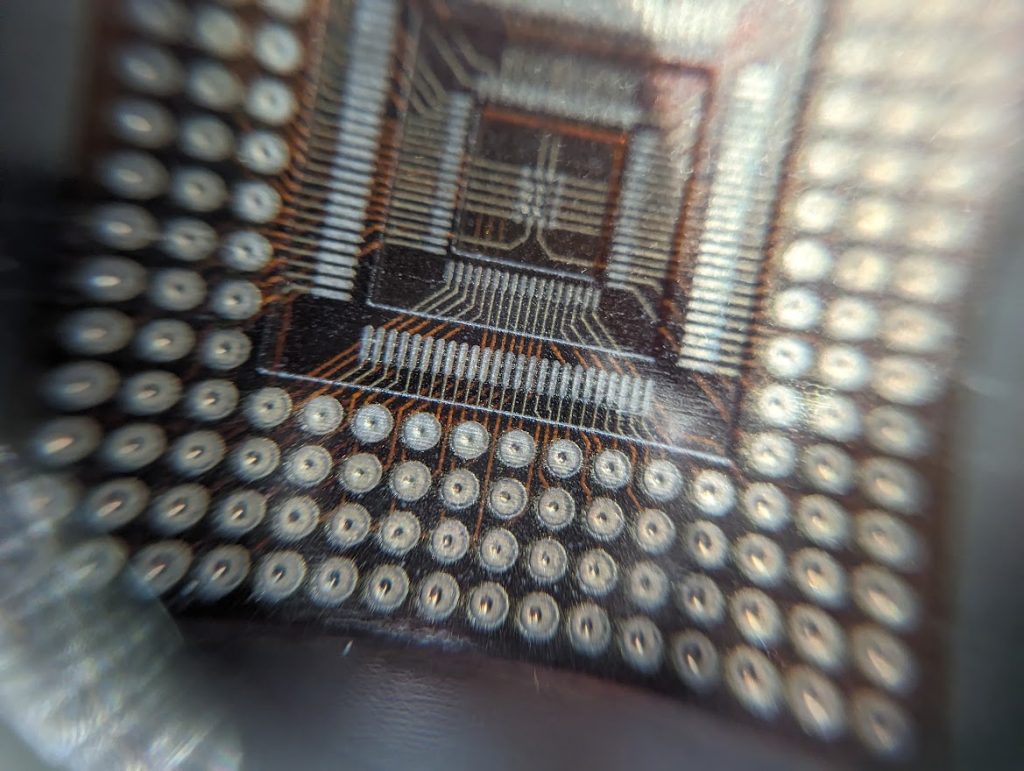

Featured image shows Nano Dimension 3D printed electronics. Photo by Michael Petch.