Researchers from the Korea Electrotechnology Research Institute (KERI) and the Ulsan National Institute of Science and Technology (UNIST) have created “core technology” for 3D printed smart contact lenses building on low-power monochrome displays and demonstrated its functionalities for augmented reality tools such as live navigation. The team’s research has been published in Advanced Science.

“Our achievement is a development of 3D printing technology that can print functional micro-patterns on a non-(planar) substrate that can commercialize advanced smart contact lenses to implement AR (Augmented Reality),” said Seol Seung-Kwon, Ph.D., of the team’s work. “It will greatly contribute to the miniaturization and versatility of AR devices.”

Why use Prussian blue ink?

Using energy-saving electrochromic (EC) displays in smart devices for augmented reality allows for producing cost-effective, conveniently manufacturable, and productively operable gadgets for specific applications. Because of the difficulty in PB micro-patterning, Prussian blue (PB), a metal-organic coordinated compound with distinctive EC properties, restrains EC display applications.

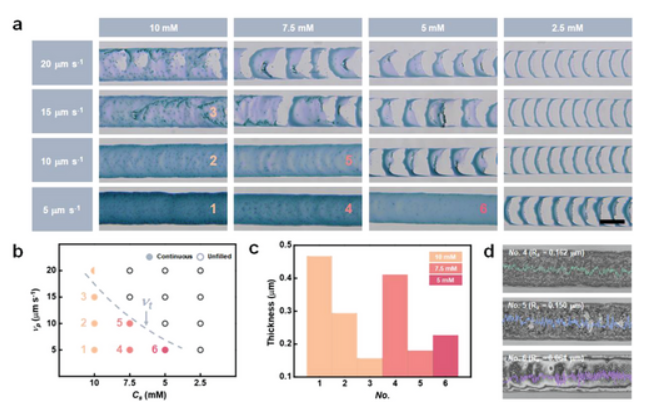

This paper describes a novel micro-printing method for PB patterns that involves localized crystallization of FeFe(CN)6 on a substrate limited by an acidic-ferric-ferricyanide ink meniscus, accompanied by thermal reduction at 120°C, resulting in PB.

Manipulation of printing parameters like the concentration of FeCl3K3Fe(CN)6, printing speed, and pipette inner diameter can result in consistent PB patterns. With 200 CV cycles, the 3D printed PB pattern is consistently and repetitively modified to Prussian white (CV potential range: 0.2-0.5 V) using a 0.1 M KCl (pH 4) electrolyte.

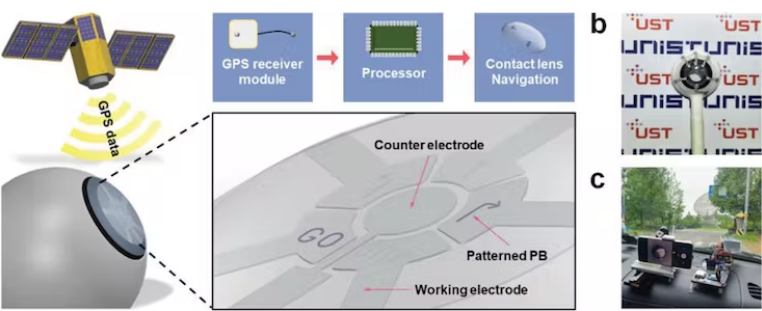

The PB-based EC display with a navigation feature incorporated into a smart contact lens can provide real-time directions to a viewer by obtaining GPS coordinates. This simple PB micro-pattern creation method could be applied to advanced EC displays and other functional devices.

3D printed smart contact lens for augmented reality

Smart contact lenses, according to researchers, are the “golden standard” of augmented reality. A smart contact lens, as opposed to the often-bulky spectacles with micro-displays and complicated optics, or the clip-on monocle design released recently by Brilliant, easily sits on the surface of the eye and overlays details on the user’s vision.

Developing a smart lens that is thin enough and runs on very little power is a struggle, and this is where the team’s 3D printing technique comes in. The researchers illustrated the capacity to print Prussian blue ink micro-patterns on the lenses, which further crystallize once the solvent evaporates.

During testing, the printing system created patterns as fine as 7.2 micrometers in size, suitable for augmented reality display usages, with a uniform and continuous color — and the researchers are optimistic that the technology will be ideal for augmented reality displays. To demonstrate this, an augmented reality smart lens with live navigation functionalities was created, projecting direction arrows and “stop” and “go” signs over the user’s vision to direct them to a site through an external GPS receiver developed employing an Arduino Uno microcontroller board.

The technology has a long way to go before it can be commercialized; for example, the mockup AR navigation lens was assessed on a 3D printed replica eyeball with a hole cut in the back to simulate what a viewer would see, but it still has to be tested on a living human’s eye.

Improving eye health with 3D printing technologies

Previously, a cornea 3D printed at India’s L V Prasad Eye Institute (LVPEI), Indian Institute of Technology (IIT) Hyderabad, and Centre for Cellular and Molecular Biology was successfully tested on animals for the first time. The synthetic material and animal residue-free cornea was implanted into the eye of a rabbit using a bio-ink created from human donor tissues. The implant’s creators claim this could eventually be “used in humans” to diagnose corneal scarring and other major eye conditions that can lead to blindness due to its “totally natural” base.

Furthermore, University of Stuttgart researchers developed a novel, dependable method for coating 3D printed lenses with anti-reflective coatings. The technique, known as low-temperature thermal atomic layer deposition (ALD), can coat multi-lens systems as tiny as 600 microns in diameter and aids in reducing light loss due to reflections between lens interfaces. Researchers claimed the breakthrough will have a significant impact on the 3D printing of good optical systems based on multiple microlenses.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows the prototype smart lens offers a number of predetermined images, which can be controlled via an Arduino Uno. Image via KERI.