A decade ago, basic 3D printers and DIY kits were sold in the Indian market to individuals or small companies for prices ranging from Rs, 40,000 to Rs.1.5 Lac.

Then it all started in 2012, when four budding entrepreneurs and friends inspired by the track record of Stratasys and MakerBot, applied to an incubator program in Manipal University to spearhead the first 3D printing business in India which was finally registered as Global 3D Labs in late 2014. Although several young entrepreneurs based out of Bangalore or Bombay have started rolling out Indian-brand 3D printers, the indigenous 3D printing industry is still maturing with the helping hands of foreign technologies and manufacturers.

According to this livemint.com report, the 3D printing industry is still maturing with many local manufacturers also providing 3D printing services and DIY kits. In many cases, these bundled offerings have imported components, but are sold under the “Made in India” label. Research firm Gartner reports that the Indian 3D printing industry has gone through a sea change since the emergence of indigenous 3D printer manufacturers.

The Indian 3D printing industry currently supports the following business models:

- Reseller companies in India sell premium brand 3D printers manufactured in Germany or USA.

- Indian entrepreneurs have set up partnerships with foreign collaborators to share 3D printing technology and manufacture printers I India.

- Indian hi-tech companies designing and manufacturing indigenous 3D Printers.

- Apart from selling 3D Printers, many India hi-tech companies are also selling 3D printing services.

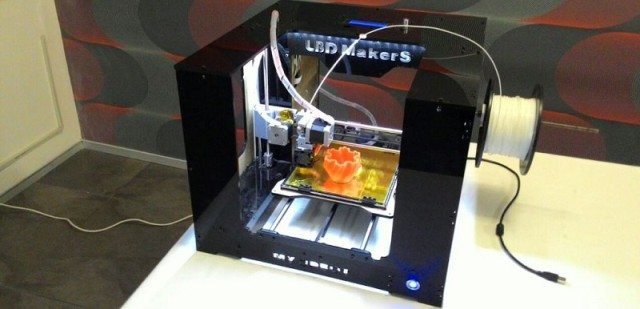

Among the Indian 3D Printer manufacturers, the one who is worth a mention is Arvind Nadig, who began his Bangalore-based venture in 2014, sold Indian-brand 3D printers at about a base price of Rs 1.2 lac to small businesses, professionals, and designers. Another Chandigarh-based company known as LBD Makers, has managed to manufacture sell a limited number of entry-level 3D Printers that cost between Rs.75000 and Rs.1.5 Lac.

My3DBot by LBD Makers India.

The rest of the Indian 3D printing technology business-owners are either reselling imported brands or offering bundled technologies that have imported components clubbed under the “Make in India” label. The next section talks about such hybrid 3D printing technologies marketed in India.

Some market applications of 3D printing technology

In the field of architecture, 3D printing has transformed the construction industry by enabling the modern architect to visualize and create precise design models, which facilitates quick design approval and faster customer input. For industrial construction, a technology known as Fused Deposition Modeling (FDM) is utilized to create industrial-strength models of parts. The most recommended 3D Printers for architectural work are 3Digi Creator 2X (base price Rs. 125,000.00) and 3Digi CubeX (base price Rs. 3,50,000.00). For miniature layouts and design verifications, both these products make invaluable tools of the trade. You can more information about 3Digi 3D printing technology here.

In the field of engineering and electronics, Altem is leading the digital revolution by empowering the product designers and engineers in India to witness their innovations much faster than before. Altem has collaborated with Stratasys of USA and SLM Solutions of Germany to deliver super-accelerated, CAD designs through the use of 3D printing process.. Due to Altem’s technology, even the manufacturing processes have started becoming agile and more personalized. Now, this technology makes it possible to manufacture production tools on the fly or create a specific number of production parts. Also, an online platform known as printmyCAD.com offers first-hand exploration of the digital product-design process.

In the field of dental technology, EnvisionTEC 3D printers are now being used in India

for a wide portfolio of orthodontic applications. CAD-based dental parts have substantially reduced the material and labor costs of dental restorations while maintaining superior clinical quality. This economical and productive technology has assured a level-playing field among the global players in dental technology. This market report predicts that by 2020, the 3D printing in dental business will grow to about 3.1 billion.

In the Indian jewelry business, Novabeans with its global partners offers the most advanced 3D printers and 3D printing services in variable price ranges. This technology delivers high-resolution, high-precision jewelry design that can do without manual finishes. Novabeans happens to be the authorized reseller of Ultimaker, 3d Systems, and b9Creator with pricing ranging between Rs 29000 and 90 Lac. The 3d printing services include on-demand jewelry printing and door-step delivery with the push of a button! See what the press finds about the future of 3D printing in Indian jewelry industry.

Now probably the Indian 3D printing industry is expectantly waiting to experience the 4D Printing technology discovered by University of Colorado Boulder in 2013.