James Brehm, a digital artist and sculptor from New Jersey, contacted 3DPI to tell us about the fascinating work he and a team of artists are carrying out within a program called the Digital Stone Project, now in its third year and supported directly by Autodesk. The workshop involves many artists who spend three weeks in Gavirazzo, a small town hidden between the hills of Tuscany, in a region called Garfagnana. This entire area is famous for its marble caves.

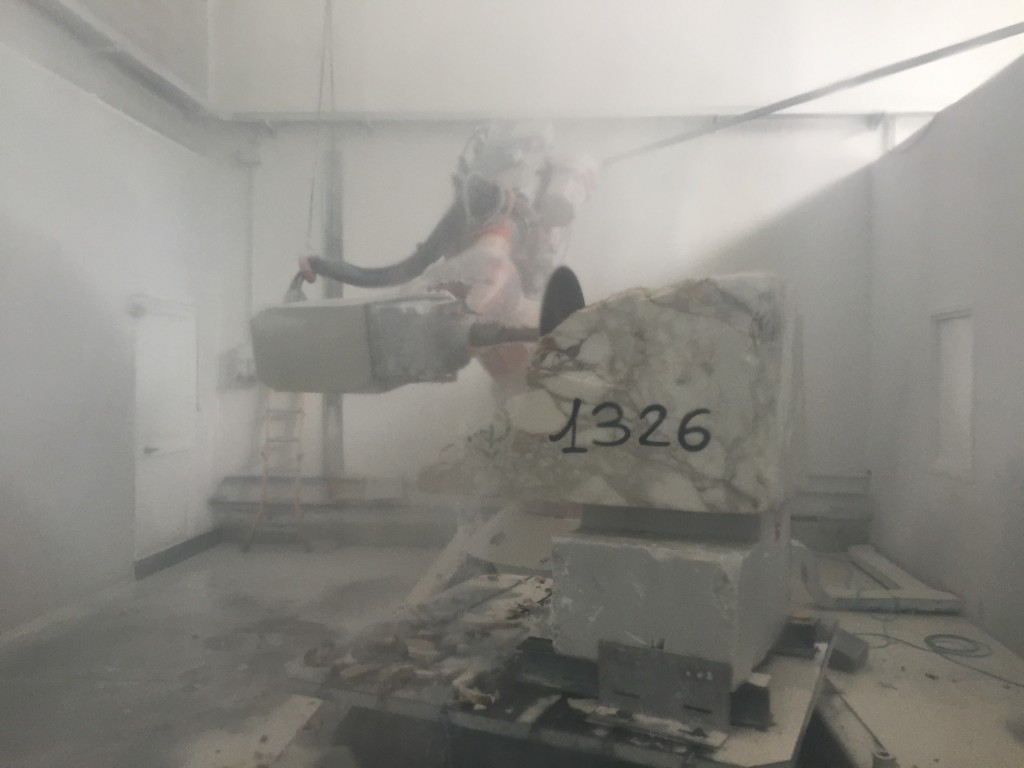

The beautiful white and grayish stone is everywhere and local artists have joined with engineers to create the Garfagnana Innovazione, a local company which experiments and now manufactures complex architectural components in marble using robots. The technique used is naturally subtractive: a large 7-axis robotic arm, similar to the Kuka Robot (which is often used for extrusion-based additive manufacturing as well) carves up the stone, based on instructions from CAD CAM files and tailor-made Gcode.

3D printing plays a minor role in this context, although it has been implemented to help both the artists and the manufacturing professionals visualize the shapes they are going to create. Since they seek to push the limits of digital manufacturing, by studying and developing new ways and directions in which the robotic arm can move, 3D printing scale models of their CAD files helps them better understand the final shape and how to achieve it.

“The challenge is to make the robot a part of the creative process,” says artist Robert Michael Smith, one of the founders of the Digital Stone Project. Smith teaches at the New York Institute of Technology and is an established experimental digital sculptor. Along with creating beautiful “biologically inspired” marble statues, he has been working with digital manufacturing technologies since 1989. He also conducted a fascinating experimental project in 2012, which used 3D bioprinting technologies to create a sculpture using live human cellular material. “The artist here needs to find a balance between the robotic work and the human work, carefully evaluating machine time and costs.” This, incidentally, is what, on a small scale, takes place inside many FabLabs.

In spite of the far out work he has produced, Robert’s approach is very down to Earth. He understands that the role of an artist is to push the limits of technology, not necessarily for a practical motive as much as for pure material and process exploration. “3D printing and digital manufacturing technologies, in general, have opened up a broad range of new opportunities, especially for artists,” he explains. “There are now an infinite number of new ways to experiment with manufacturing and the truth is that the only limit is in our own minds. That is why the role of the digital artist is so important.”

The Digital Stone Project is a Not-for-Profit technology organization led by President Jon Isherwood and supported by Autodesk with scholarships. It is open to both professionals and art students who want to take advantage of the unique robotic marble carving capabilities of the Garfagnana Innovazione Facility.

At the time I visited, there were about 20 artists coming mostly from several different US colleges and universities, each with their own very unique ideas and inspirations. The final versions of the projects they were working on had already been 3D printed thanks to two MakerBot Replicator 2 machines, supplied by local MakerBot distributor Energy Group. Garfagnana Innovazione also has access to a Stratasys Mojo 3D printer, used mostly for pre-prototyping activities of the larger architectural projects they work on.

Gabriele Ferri is the engineer who is in charge of programming the robots for Garfagnana Innovazione, using specific CAD CAM software to moving progressively form the initial block of marble to the final work. “We were founded with support from the EU’s Horizon financing program,” Ferri explained. “We started mainly as an academic institution and evolved into an actual production facility for large art and architecture projects with large marble stone pieces. We are not the only ones offering these services. The robotic arms offer better geometrical capabilities through 7 axes, with lower precision and also lower costs compared to large size CNC mills. Through the Digital Stone Project, we want to work with the artists to use the machines to create works that would be impossible to create through any other method.”

Working with digital and robotic technologies thus enables the artists to be inspired by generative, complex and repetitive geometrical shapes, such as the Fibonacci spiral of a pineapple or computer elaborations of data spanning over long period of time. All the works are to be displayed at an exhibit set to take place in Florence.

Some of them – including three of Robert’s sculptures – will remain in Italy, as marble is extremely heavy and expensive to transport. The 3D printed versions of their works, on the other hand, can be sent anywhere instantly and manufactured on location, perhaps even with a Marble-based filament like Treed’s Monumental, which I brought to Garfagnana for the artists to test. The feeling of the marble filament is not the same as real marble but it is significantly more affordable to ship. Each technology has its advantages and uses.