At the recent Inside 3D Printing conference in Melbourne, we had time to sit down with Omer Krieger, Stratasys’ General Manager for Asia Pacific and Japan. We learned what excites him about 3D Printing’s future in Australia and beyond, and reading between the lines, where Stratasys will fit into the mix. This allowed us to think through Krieger’s ideas about how 3D printing will shape the ways we’ll be living next.

How we live by the goods we get

Before we get into the conversation with Krieger, consider that, over the last few centuries, a number of specific technologies have changed the patterns of production and trade. Shipping allowed access across the oceans, railways opened up continents, and highways allowed freight to find customers in ever-expanding cities and suburbs.

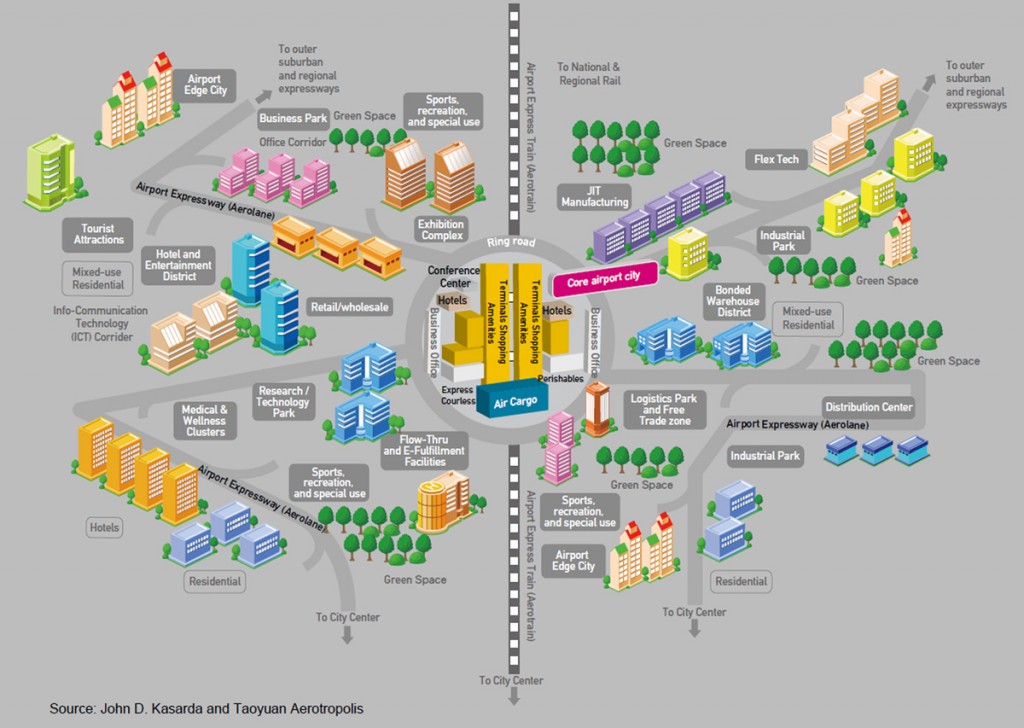

More recently, the trendy-again urban planning concept of ‘aerotropolis’ suggested that the new input-output interface of modern 21st century economies would be the airport. No longer would our intercity connections be defined by the land and sea. And, putting aside terrorism, climate change, and resurgent localist cultures, globalization was coming, again, and with wings on.

In this vision of the modern ‘aerotropolis’, airports function as physical hubs that grow cities around them, aided by internet-based commerce and vastly extended supply chains that crisscross along flight routes.

The business scholar John Kasadra explains aerotropolis through his ‘law’ of connectivity: electronic connections lead to physical connections. Give a town the internet, and the airport to support Amazon.com orders will follow. Or so the theory goes. Connections of commerce grow around the airport like spokes on a wheel.

So, with this in mind, does 3D printing offer an alternative narrative for how we’ll live next? And is Statasys trying to be a part of it? Or more specifically, can distributed additive manufacturing hubs invert the hub and spoke relationship of commerce noted above, when Kasadra’s ‘law’ reaches its asymptote as digital bits literally assemble into physical ones?

Stratasys’ place in a 3D World

Stratasys‘ Lead in Asia Pacific and Japan, Omer Krieger, understands part of the strategic value of 3D printing in terms of how it can enable ‘fabrication nodes at any specific point’ across the globe. He submits that these fabrication points allow new types of manufacturers to quickly produce diverse products for both local and global clients. Krieger points out that, for locations like Australia, additive manufacturing represents the only real ‘just in time’ solution for flexible and highly iterative manufacturing. Evidence suggests that lower labour costs and better economies of scale will (always) exist elsewhere, but Kreiger argues that, for the ’need it now’ economy, 3DP will prosper.

He also sees mass-custom manufacturing to offer other opportunities for countries like Australia that are positioned outside of large markets or supply chains. The marriage of ICTs and 3DP enables manufacturing cultures, innovators, and capacity to emerge around the globe in a much more rapid and distributed fashion than any process of industry-clustering before it. To editorialise this trend: additive economies disrupt agglomerative economies.

While most first year economics courses would point out that globalization has already made manufacturing a mobile commodity, following capital and cheap labor around the world, the importance of geographic concentration for traditional manufacturing remains. Gary Pisano of Harvard Business School reminds us in a recent discussion paper (PDF) that ‘geographic concentration is still valuable’ as clusters of ‘production activity [shift] from one location to another’ for multiple reasons that industries and locations ‘sticky’.

Yet, in talking with Krieger, it seems that the needs being met by Stratasys through 3D printing are of a different category. He cited an example of a client who, on a suddenly abbreviated timeline, opted to additively manufacture new key components in four different continents simultaneously and have these shipped on time to a specific ‘end market’ from all across the world.

It seems that, rather than completely distributed manufacturing networks built on 3D printing, part of Stratasys’ business plan is positioning itself as a centralising manufacturing-services hub in a growing geographical network of 3D printing capacity. This positioning is evident when you consider how, for instance, Stratasys Direct Manufacturing is an amalgamation of services from Harvest Technologies, RedEye, and Solid Concepts.

Customer creativity required

In this model, Krieger suggested that it is the creativity of customers that drives the business. Effectively harnessing that creativity is a challenge that requires new ways of designing and teaching. Stratasys considers GrabCAD and Thingiverse as ways it is building professional and consumer communities to enable learning, but Krieger hopes that primary to tertiary education policies and practices substantively change to enable a new generation of makers to grow up physible, if we may coin another phrase.

This, of course, means selling more printers, which serves Stratasys just fine. But, cynicism aside, Krieger makes a clear point when he compares 3D printing to learning environments employing 2D printing. It would be horribly strange, he notes, if only teachers, TAs, and professors were able to print things in school. While he admits that the inputs and outputs of 3D printing are completely different to 2D practicalities, content is still key; opening accessibility to create content will be crucial.

To allow the 3D printing ‘revolution’ to catch on in a similar fashion to desktop publishing, Krieger suggests opening interfaces and APIs of printers in the hopes of delivering seamless integration between software and hardware and enhance accessibility. To illustrate his point, Krieger jokes that, when he wants to print a report, he hits print and, ‘I don’t know how, but it just prints’. 3D printing also has to be that accessible for it to enable the creativity of anyone who comes across a printer.

Does Krieger think there will be a ‘LaserWriter’ moment, as, when 30 years ago, GUI, PostScript and interconnectivity suddenly allowed every desktop to professionally print whatever it wanted? (The price tag for Apple’s LaserWriter setup would be $15,000, inflation adjusted USD in 2015) Krieger pauses, and considers that, while he envisions a slower more gradual change, he hopes he’ll be proven wrong and waits to be happily surprised by whatever agglomeration of interface, community, education, and technology can turn that corner.