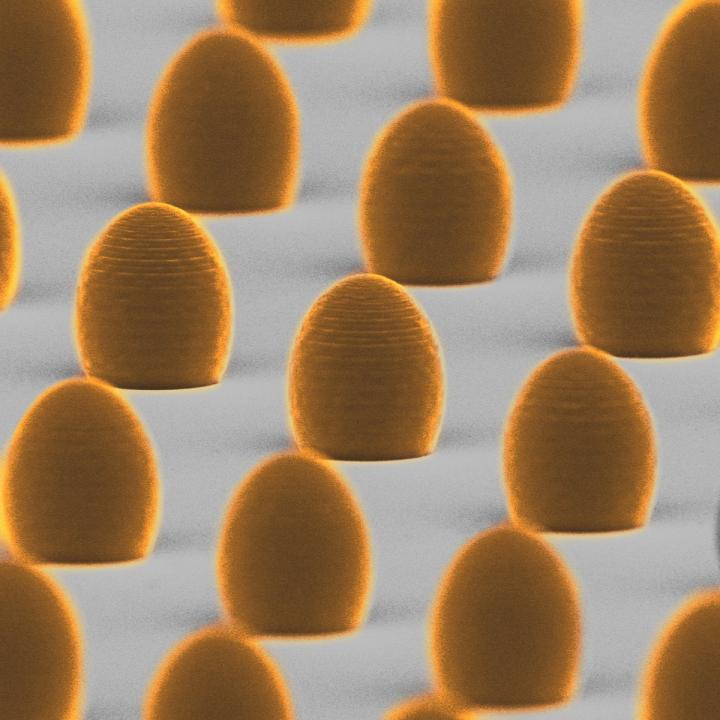

Researchers at the University of Warsaw, Poland, have designed micrometre-sized lenses using a Direct Laser Writing (DLW) 3D printing technique. The 3D printed lenses can be fabricated on top of various materials, including fragile graphene-like materials.

The research team, based in the Faculty of Physics, explains that the lenses can replace bulky microscope objectives that were previously required for performing spectroscopic measurements of single nanometre-sized light emitters, like quantum dots or atomically thin 2D materials.

Additionally, these bulky microscopes had to be placed at a distance of about one-tenth of an inch from the sample to be analysed, which can impose limitations on many types of modern experiments. The proposed 3D printed lenses, according to the researchers, increase the working distance between the lens front and the sample surface, by over two orders of magnitude. This potentially opens up new perspectives for a wide class of optical experiments.

Producing microlenses with 3D printing

The researchers set out by explaining that commercially available 3D printers have been experiencing rapid development, which has coincided with its compatible materials, including transparent media of high optical quality. The advancement of 3D printing technology alongside such materials opens up new possibilities in many fields of science and technology including biology, medicine, metamaterials studies, robotics, and micro-optics, the researchers state.

Demonstrating its applications in light extraction and delivery, the authors of the paper explain that they have developed efficient elliptical microlenses that can be 3D printed on top of light emitters. These lenses are described by the authors as “simple, cost effective, broadband, versatile and compatible with other components of widely desired micro-optical systems,” while also operating without high-numerical-aperture optics.

To manufacture the lenses, which can be fabricated on a wide variety of samples, the team opted to use the DLW 3D printing process, which is described in the paper as “a versatile technique capable of printing lenses of virtually any shape.” DLW is also known as two-photon 3D photolithography, a process that enables the production of arbitrary 3D nanostructures.

Such technology is provided by the likes of Nanoscribe, a German manufacturer of two-photon additive manufacturing systems. Last year the company introduced the Quantum X, specifically designed for fabricating nano-sized refractive and diffractive micro-optics which can be as small as 200 microns.

In late 2019 researchers from Lawrence Livermore National Laboratory (LLNL) and The Chinese University of Hong Kong (CUHK) achieved a breakthrough in the development of two-photon additive manufacturing, accelerating the technique’s manufacturing speed while limiting the sacrifice of resolution.

Advantages of ultra-long-working-distance spectroscopy

A key property of the 3D printed lenses presented by the authors is that they are able to increase the extraction of light emitted from semiconductor samples and reshape its outgoing part into an ultra-narrow beam. Thanks to this property, the researchers explain that the lenses can help to eliminate the need for bulky microscopes required for performing optical measurements of single point-like light emitters. The 3D printed microlenses also enable long-working-distance optical measurements (600 mm with a 1-inch collection lens), which are not accessible to date with other spectroscopic techniques, according to the authors of the paper.

Typically, standard spectroscopic microscopes measure roughly a handbreadth size, weigh up to one pound (half a kilogram) and must be placed at a very small distance from the sample. This can cause problems when attempting to produce measurements in pulsed high magnetic fields, at cryogenic temperatures or in microwave cavities, which on the other hand can easily be lifted by the 3D printed lenses presented by the research team.

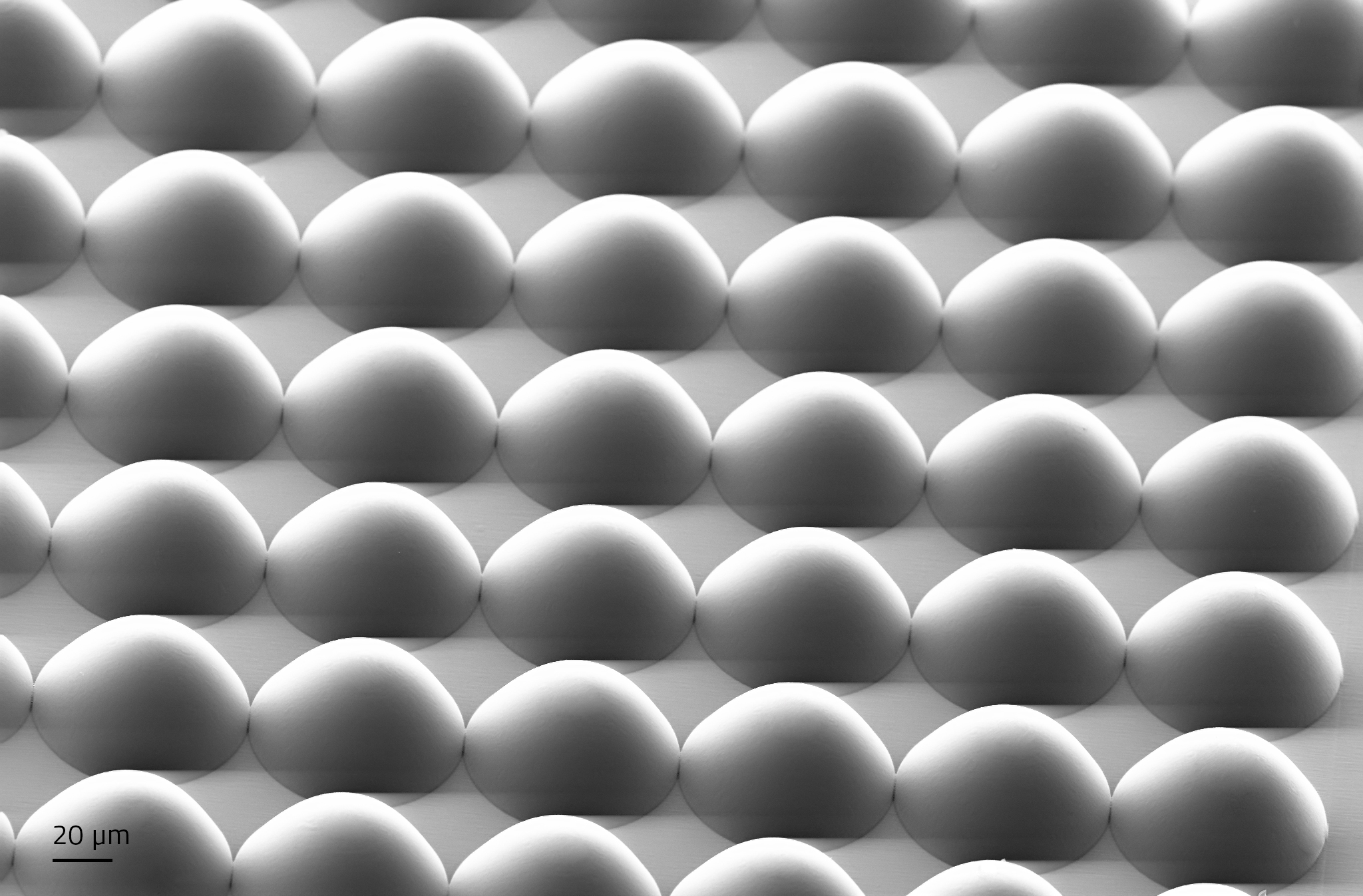

Additionally, the high-speed capabilities of the DLW 3D printing process means that it is possible to produce hundreds of microlenses on one sample, which can help to enable much more time-efficient research and hypothesis testing. “Arranging them into regular arrays provides a convenient coordinate system, which accurately specifies the location of a chosen nano object and allows for its multiple measurements in different laboratories all over the world,” the researchers explain.

The research paper, “Ultra-long-working-distance spectroscopy of single nanostructures with aspherical solid immersion microlenses,” is published in Light: Science & Applications, 9, 1 (2020) (https://doi.org/10.1038/s41377-020-0284-1). It is written by Bogucki, A., Zinkiewicz, Ł., Grzeszczyk, M. et al.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows scanning electron microscope image of 3D-printed aspherical microlenses. Photo via University of Warsaw.