Researchers from National Central University, Taiwan have developed a UV and heat resistant, self-healing emulsion glass. The impressive arsenal of properties makes the liquid-like solid (LLS) material perfect for a supporting medium, whereby UV and heat-curable inks (aka resins) can be ‘3D written’ directly into it and cured independently of the surrounding LLS.

Liquid-like solids and 3D writing

According to the researchers, LLS materials can be used as a robust supporting medium for liquid inks. Using them to hold the ink in place while the ink solidifies helps maintain the intended written geometry. Without a supporting medium, gravity and the surface tension of the ink would result in fluid instability (a hot mess).

For example, PDMS, an elastomer, is biocompatible, non-toxic, and optically clean which makes it useful in lubricants and antifoaming agents. Despite being UV and heat-curable, its applications are largely limited to its fluid form due to its extremely low prepolymer viscosity and long curing time. Therefore, on its own, it’s unable to maintain its desired 3D shape long enough for it to cure, so it’s very difficult to 3D print. Recently, this issue has been solved by 3D writing the liquid PDMS into an LLS holding medium and curing it once it’s been suspended.

Self-healing emulsion glass

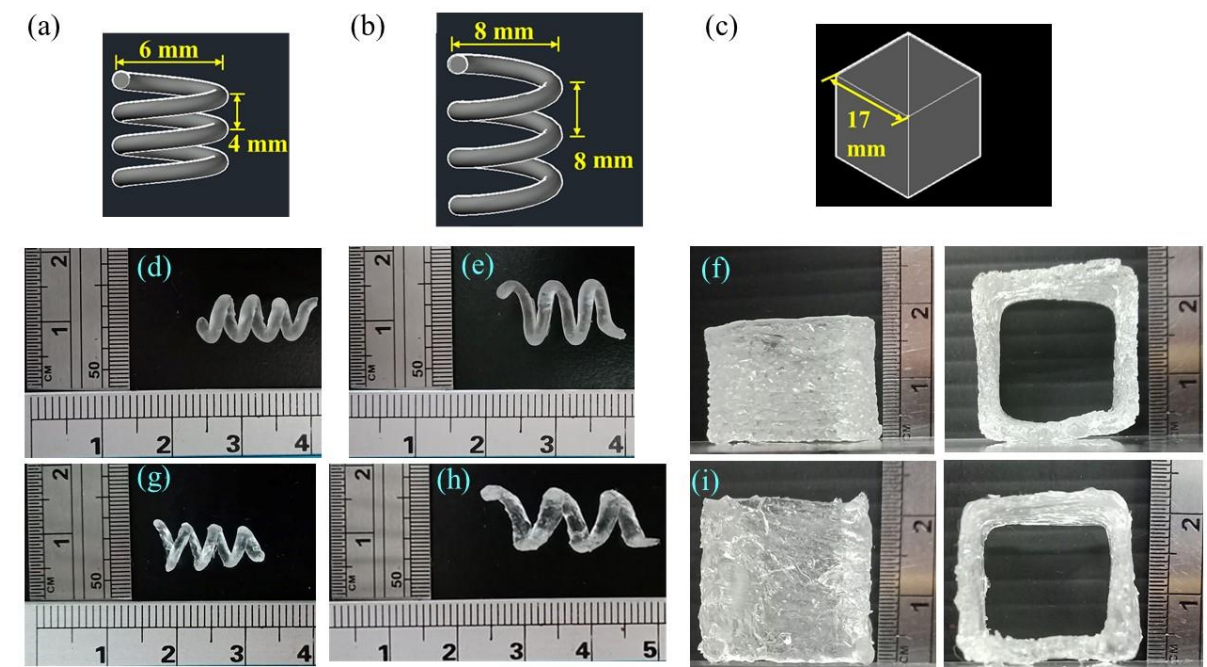

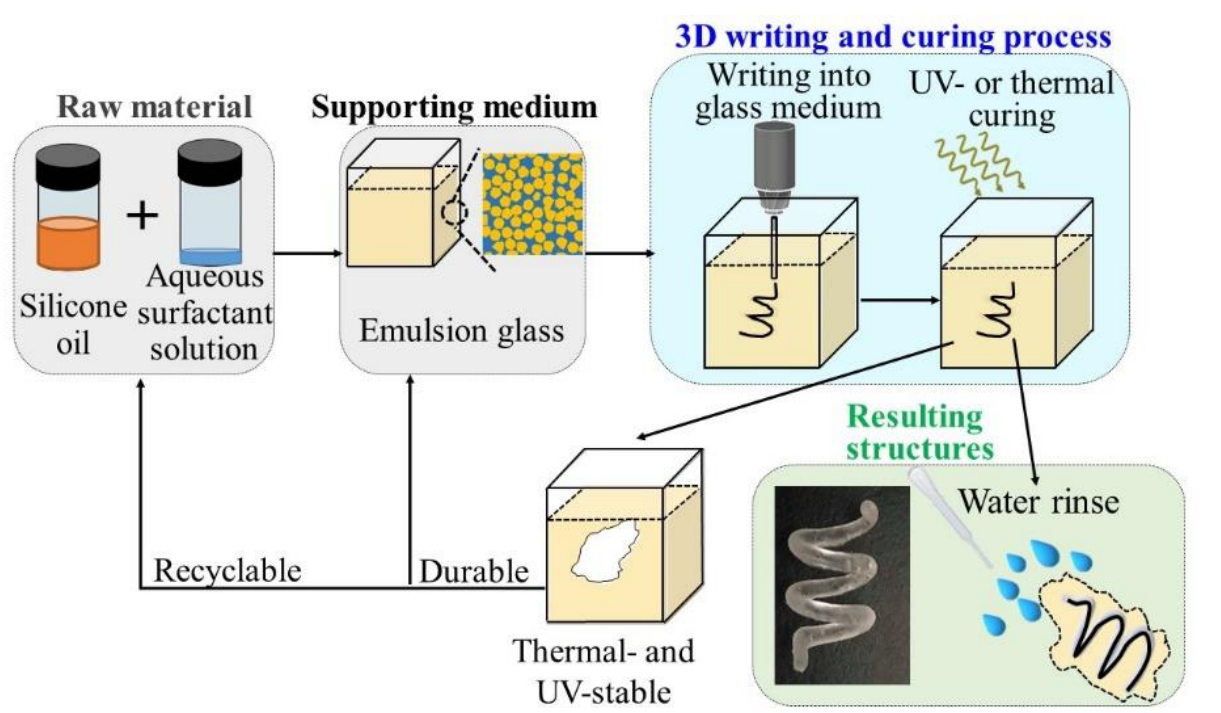

With the aim of developing the next-generation of supporting media, the research team first mixed a specially formulated silicone oil with sorbitol and water to form an aqueous solution. From this, they extracted a “stable emulsion glass” which would go on to be used as the experimental supporting medium. The team opted to use PDMS elastomer as the ink which would be 3D written into the emulsion glass and cured. The 3D writing device (a syringe pump with a nozzle diameter of 1.83mm) was constructed from scratch.

3D structures were modeled and written into samples of the emulsion glass and cured with heat and UV light to demonstrate the glass’ suitability as a supporting medium. For the UV process, a 365nm UV lamp was used for 60 seconds and for the thermal process, the ink-glass samples were heated in an oven at 100°C for an hour. Even after six runs of UV and heat exposure, the emulsion glass remained unphased and maintained its structural integrity, giving it its UV and heat resistance. This meant that the glass could be used to cure UV and heat-sensitive inks at the same time.

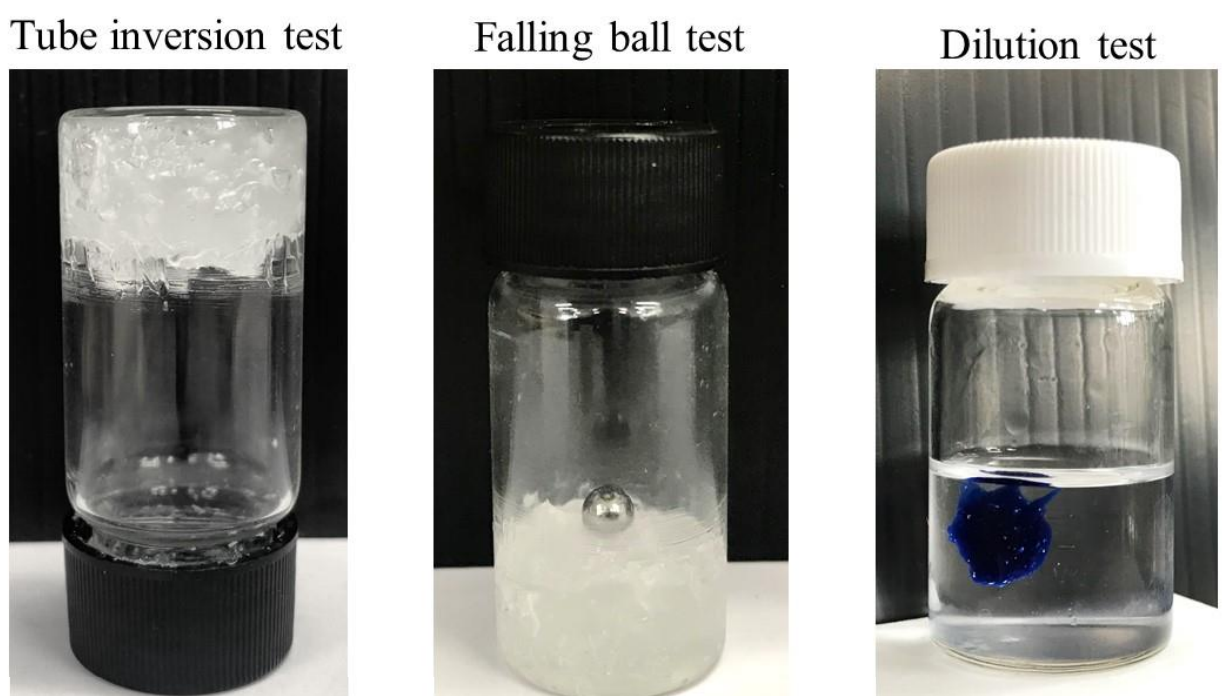

The researchers also concluded that the densely packed oil droplet structures in the aqueous matrix gave the glass its extreme elasticity. This translated to a “self-healing” ability where any holes or incisions made in the glass would automatically close over.

Further details of the study can be found in the paper titled ‘UV-resistant Self-healing Emulsion Glass as a New Liquid-like Solid Material for 3D Printing’. It is co-authored by Ssu-Wei Hu, Pin-Jung Sung, Thao Phuong Nguyen, Yu-Jane Sheng, and Heng-Kwong Tsao.

While the Taiwanese scientists used glass to aid in the 3D printing process, some researchers have taken it a step further and developed 3D printable glass. Towards the end of last year, a group of scientists at ETH Zürich, Switzerland, 3D printed glass structures using a modified resin and DLP 3D printing technology. The printed glass parts had high spatial resolutions and multi-oxide chemical compositions. Elsewhere, in Canada, researchers at Université Laval developed a novel method of 3D printing glass to be used in laser and infrared optics systems as well as telecommunications devices.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed PDMS helix structures. Images via National Central University.