Breaking a bone or scraping parts of it due to continuous movement or injuries could lead to complex and hard to solve medical cases. Recent developments in 3D printing now allow doctors to study exactly what they need to replace, with the precision required for the uniqueness of a person’s body, in order to prepare for an operation or develop the perfect internal prosthesis through the use of surgical guides.

Today not all medical clinics have working 3D printers and trained personnel to design and print the bone parts they need in order to help patients: the day that hospitals will have their own 3D printing departments may still be a while away: this is the gap that Osteo3D intends to fill.

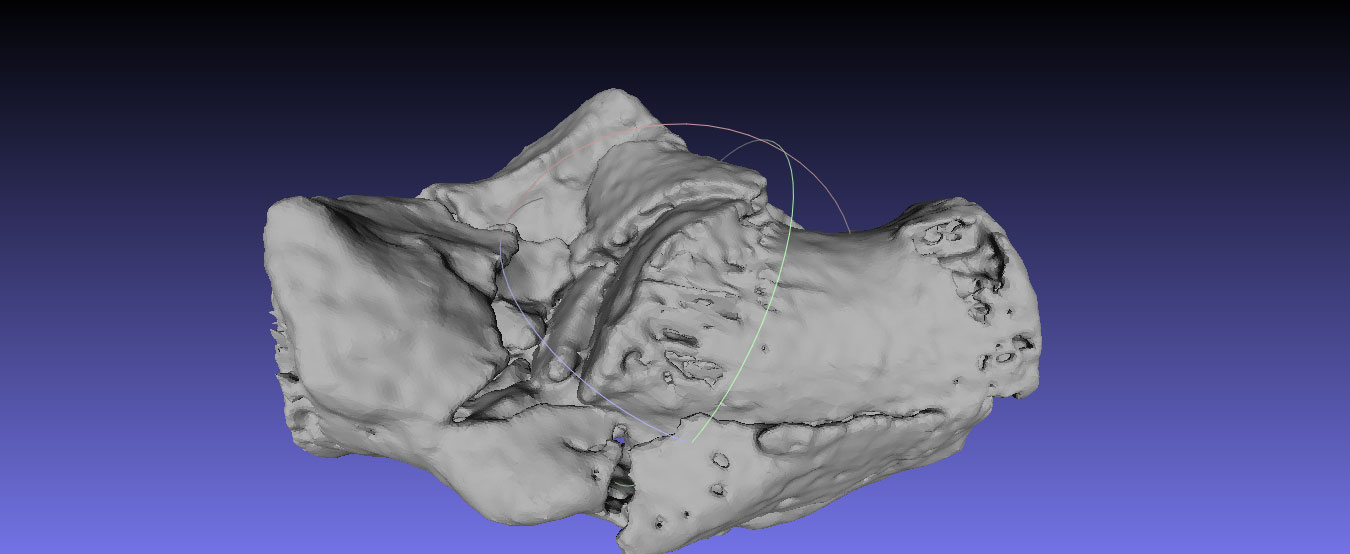

Powered by df3d, a cloud based design platform for 3D printing, Osteo 3D gives doctors around the world the opportunity to order the parts they need to have printed and then get them delivered to their labs and operating rooms. All one has to do is share information and designs about the parts they want to get printed. These may be digital medical DICOMM (from CT and MRI scans) images of various parts of the body that a doctor needs to assess in three dimensions.

Possible applications of the models besides direct implementation to the body are to estimate the seriousness and extent of an injury, to plan a surgical procedure, or to use models for educational and explanatory purposes. Another very useful application of Osteo3D models is the creation of surgical guides. These guides demand highly tailored parts that will help doctors work within certain preset tolerances and accurate placement of implants.

The df3d design factory is a project carried out by Amin Torabi, who also co-founded the first 3D Print Cafè in Berlin, Dimension Alley and, even then, he had told us that the most requested prints were related to the medical field. The cafe was built to allow people to print high quality pieces of whatever their imagination begets and then sell them on their dedicated marketplace where you can see some samples of exceptional detail. This experience with detailed designs guarantees the high precision and meticulousness with which the models are created from the people behind Osteo3D. These may be just details for other applications, but for the medical sector accuracy is of critical importance.

Accurate, personalized 3D printed medical models and parts are no product of the imagination anymore. We may not have reached the point where every doctor can print what he/she needs, but services such as Osteo3D are making this possibility available to more medical professionals than ever before and this may prove to be a huge step towards the solution of many previously unsolvable cases. This is truly one of the most profound and direct ways that 3D printing technology is helping humans stay healthy or even alive.