3D-Fuel, a USA-based filament manufacturer, has partnered with multinational chemical company Dow to provide the latter’s IMAGIN3D Polyethylene Olefin Block Copolymer (OBC) product to the North America filament market.

Dow’s IMAGIN3D Polyethylene OBC is designed for the production of lightweight, durable 3D printed parts. Based on polyethylene, it retains the material’s inherent properties, while maintaining dimensional stability during the printing process.

Focus on sustainability

Based in Fargo, 3D-Fuel aims to deliver a range of specialized 3D printing filaments with a focus on eco-friendliness and sustainability. The company has manufacturing facilities in Fargo and Moville, Ireland for shipping to the EU. 3D-Fuel maintains its environmentally friendly footprint by using NatureWorks Ingeo PLA for a majority of its products. This material is made in the US from plant-based plastic made from corn; it is compostable and made without any oil-based products.

3D-Fuel’s dedication to sustainability is carrying over in its collaboration with Dow. Both firms have committed to the circular economy by taking into account the product’s complete lifecycle, particularly during development, as part of Dow’s 2025 sustainability goals.

Dow in the 3D printing industry

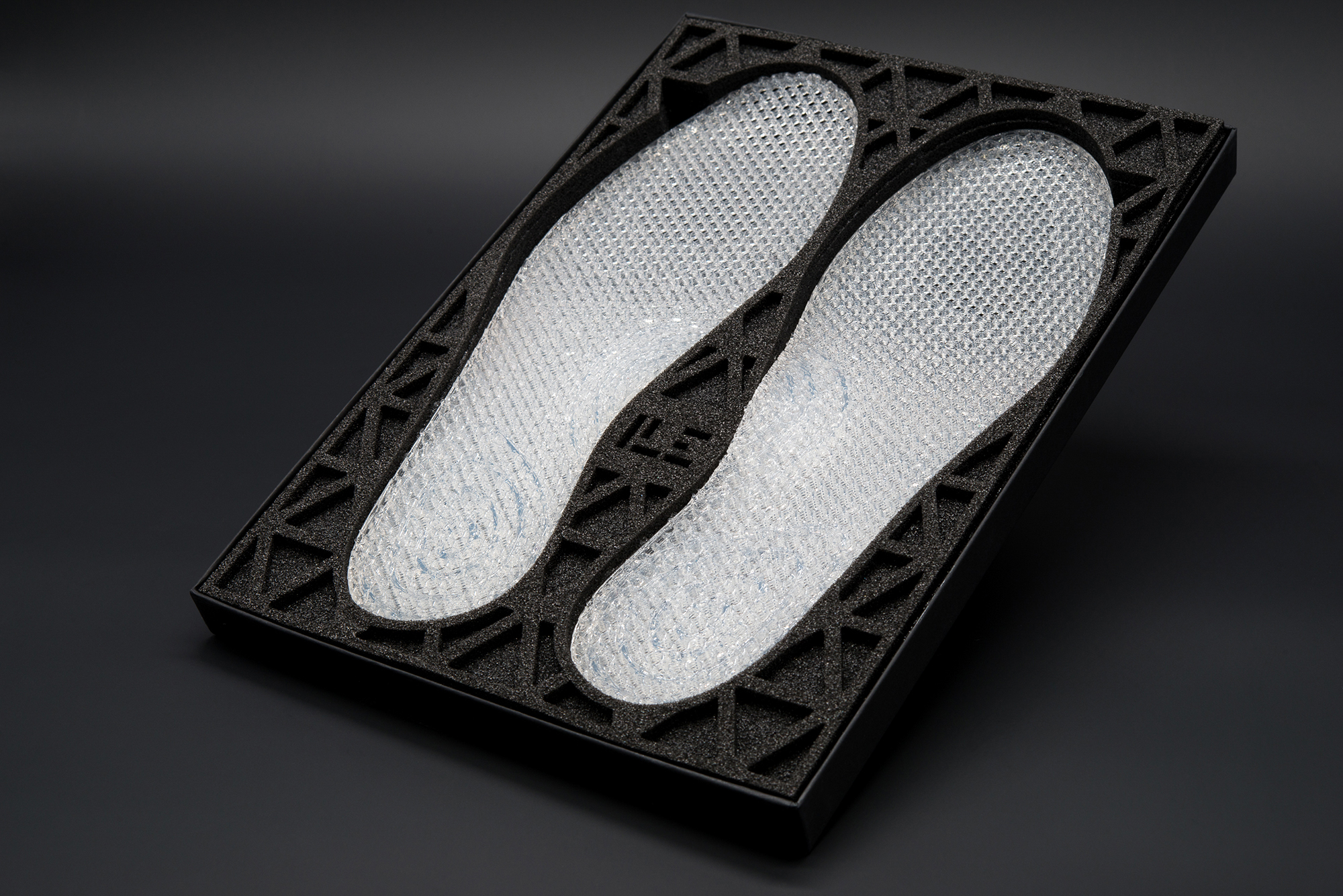

Dow’s filament, the IMAGIN3D Polyethylene OBC, provides a number of material benefits. This includes elongation of break over 800 percent, low density, high durability, chemical resistance for use in corrosive environments, low flexural modulus and high fatigue resistance. As such, the filament can potentially enable new applications where ductility and durability are valued, for example, in the production of living hinges, or for UAV, automotive, marine, and R/C applications.

A materials science company with a history dating back to 1897, Dow has amassed a large portfolio of performance materials, industrial intermediates, and plastics businesses. The company aims to deliver a broad range of science-based products and solutions for customers in high-growth segments, such as packaging, infrastructure, and consumer care. Dow operates 113 manufacturing sites in 31 countries and employs approximately 37,000 people.

In 2017 Dow merged with fellow chemical company DuPont to form DowDuPont, which has since spun-off to form three separate divisions with focuses on the following: agriculture, materials science, and specialty products. The agriculture division is named Corteva, the materials science spin-off is named Dow Inc., and the specialty products division is named DuPont.

Dow originally announced its entry into the 3D printing materials market with the launch of the EVOLV3D Universal Support Material (USM) in 2017. Since then, the company has grown its presence in the industry. In 2019 its filaments became available through MatterHackers, a California-based 3D printers and filament supplier. The company’s 3D printing materials have also been used to produce footwear in a collaborative project with French software provider Dassault Systèmes, and Danish shoe manufacturer ECCO. Additionally, it showcased a range of high-performance materials for 3D printing with DuPont last year at RAPID + TCT.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows IMAGIN3D Polyethylene Olefin Block Copolymer filament. Photo via 3D-Fuel.