3D Systems is set to release the full set of results for its latest Figure 4 material tests. The tests conducted on the production-grade range were against both ASTM and ISO standards.

The results will be published on March 23rd. The comprehensive list can be utilized by engineers and designers to rapidly decide on a material for any given industrial application, eliminating the need for additional in-house testing.

3D Systems’ material tests

Released material testing results tend to be limited in their detail, meaning manufacturers are usually forced to conduct additional independent tests before deciding on a material. By releasing details of the process as well as the certification verdict, 3D systems aims to save customers time, reduce costs, and speed up their time to first part and production.

An extensive list of properties that led to certification including long-term environmental stability, electrical data, UL94 flammability, biocompatibility, ISO mechanical properties, isotropic mechanical property tolerances, and compatibility with automotive fluids and chemical reagents gives clients free rein to begin manufacturing prototypes from the very beginning.

Marty Johnson, technical fellow at 3D Systems, states: “Until this point, materials testing data provided by the industry has been incomplete for production applications and of little value to engineers accustomed to data that accompanies injection molded plastics.”

He adds, “If an engineer is going to use any material for true production applications, they need a comprehensive set of data which meets industry standards in order to evaluate its efficacy. 3D Systems recognizes how these standards help improve product quality, enhance safety, facilitate market access and trade, and build consumer confidence. Testing to both ASTM and ISO standards allows us to address a broad set of manufacturers worldwide and usher in the use of AM for true production.”

The Figure 4 platform

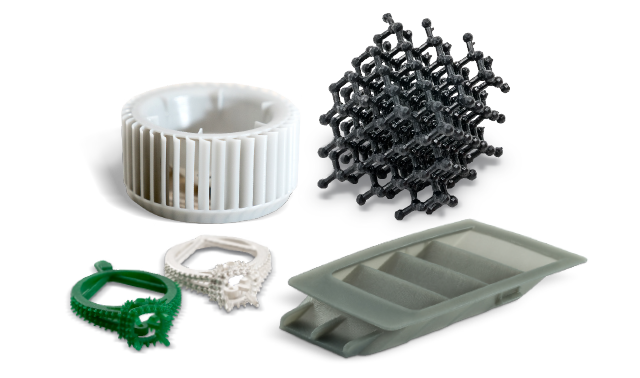

The tests were conducted on the latest eight 3D Systems Figure 4 materials, including HI TEMP 300-AMB and TOUGH-BLK 20. The Figure 4 range of materials are host to a variety of desirable industrial-grade properties such as heat deflection, UV stability, durability, flexibility, and impact strength.

However, the materials are only a subsection of the whole Figure 4 platform, which is made up of 3D printers, complementary software, and a plethora of production-grade materials. One of the 3D printers provided in the Figure 4 range is designed to be scalable according to factory production needs, with multiple modular, semi-automated systems working in unison for maximum output. 3D Systems has also previously released Figure 4 machines optimized for jewelry production. With multiple machines suited for different applications and a comprehensive list of tested materials, 3D Systems aims to allow manufacturers to rapidly produce end-use parts with a simplified workflow.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D Systems headquarters. Photo via 3D Systems.