According to Gartner, one of the most futuristic technologies in the 3D printing space is actually much closer to realizing its potential than you’d imagine. Already in the past year we’ve seen 3D printed thyroids, 3D printed mini kidneys, and functional tissue. Now, researchers at University of Toronto Engineering have pioneered a “person-on-a-chip”, capable of growing human tissues for medical testing and, possibly one day, organ transplantation.

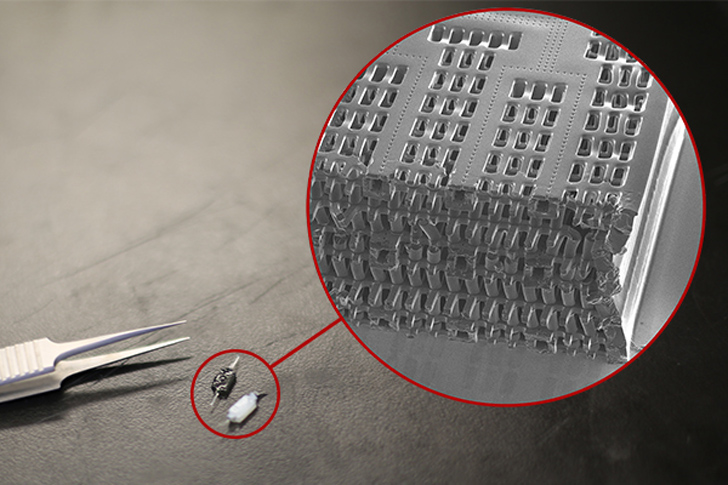

Published in the journal of Nature Materials, the U of T team describes what they call the AngioChip, consisting of a scaffold made from POMaC, biodegradable and biocompatible polymer. Rather than 3D printing the scaffold with an extruder, as occurs with Organovo’s technology, the layers of the chip are stamped and stacked. Each layer contains small channels, about 50 to 100 microns wide. Once the layers are stacked, resulting in a a network of blood vessels, the object is UV-cured and placed into a culture of living cells that attach to the AngioChip and begin growing.

The power of the AngioChip is that it accurately reflects the actual environment of the human body, allowing human cells to grow as they would in their natural surroundings. Professor Milica Radisic, who led the research, describes the AngioChip to U of T Engineering News, “It’s a fully three-dimensional structure complete with internal blood vessels. It behaves just like vasculature, and around it there is a lattice for other cells to attach and grow.” She continues, “Previously, people could only do this using devices that squish the cells between sheets of silicone and glass. You needed several pumps and vacuum lines to run just one chip. Our system runs in a normal cell culture dish, and there are no pumps; we use pressure heads to perfuse media through the vasculature. The wells are open, so you can easily access the tissue.”

So far, the team has used their technology to create models of heart and liver tissues that behave the same way their authentic counterparts do. The live cells, for instance, metabolized medication and even produced urea, essential for processing nitrogen in the bodies of mammals. More than that, however, Radisic’s group was able to connect the blood vessels of their artificial heart and liver in order to see the two systems interact. Injecting white blood cells into the vessels, they observed the cells move from one organ chip to the other.

As with previous developments in bioprinting, the AngioChip would help the pharmaceutical industry ween off of animal testing and get drugs to market more quickly. With the ability to connect different organ tissues, however, they’re able to expand upon other initiatives to see how these drugs affect the interactions between organs. In the future, Radisic believes that the AngioChip could involve into complete tissues for implantation, to repair damaged organs with cells from a patient’s own body. The artificial blood cells from the tissue would connect with a host’s own circulatory system, while the polymer scaffolding biodegrades in the course of a few months.

To commercialize the technology, Radisic has founded TARA Biosystems Inc. and is working on methods for mass producing the AngioChips. At the moment, there is a lot of manual work involved, but, once they are capable of increasing their output, their technology could change just about everything in the bioprinting and medical industries.