In this article, we review the UltraCraft Reflex, the latest resin 3D printer from Chinese digital solution provider HeyGears.

Featuring a 6K resolution mono LCD screen, this desktop-sized VAT photopolymerisation 3D printer marks the company’s entrance into the consumer market.

Competitively priced and easy to use, it offers precision, accuracy, and the ability to achieve high surface quality. This makes the UltraCraft Reflex a good option for those wanting to incorporate resin 3D printing into their design and production workflow for the first time.

This review will also evaluate the UltraCraft Reflex’s washing station and curing unit, which come as part of the UltraCraft Reflex Combo package. We also assessed the UltraCraft Pulsing Release Module, an optional extra which uses high-frequency vibrations to reduce peeling force and increase 3D printing speeds. These post-processing systems are designed to be an all-in-one solution for the straightforward production of high-quality parts.

The UltraCraft Reflex Combo package can be purchased from the official HeyGears store, with prices starting at $2,389. Alternatively, the resin 3D printer can be purchased individually for just $1,399.

Why choose the UltraCraft Reflex?

Customers choosing resin 3D printers over extrusion-based FDM systems often do so to achieve higher precision parts that feature intricate details. The UltraCraft reflex delivers on these requirements, offering XY precision of 33 μm and 25 μm Z-axis precision. Our testing confirmed the 3D printer’s ability to produce accurate parts with good surface quality and impressive fine details.

For those wanting to achieve batch production of identical parts, consistency and repeatability is essential. The 3D printer’s high precision makes it a good option in this regard, achieving 93% part consistency in batch production testing and scoring well on repeatability.

A generous build volume of 192 mm x 121 mm x 220 mm, or 5.11 liters, is also incorporated into the UltraCraft Reflex. This is above average for the desktop resin market, making the 3D printer well suited to a range of applications including prototyping, model making, and functional consumer products.

Newcomers to resin 3D printing can find the calibration and set-up process to be complicated, time-consuming and frustrating. Therefore, the UltraCraft Reflex is an ideal choice for users wanting to achieve quick and easy 3D printing.

The resin filling and heating function automatically manages the resin level in the tank, refills resin when needed, and heats the material to the ideal temperature for 3D printing. This feature alleviates any concerns regarding resin uniformity, ensuring consistent results even in colder environments. Additionally, the auto zeroing and precise bed leveling functions reduce the need for manual adjustment, further streamlining the 3D printing process.

The UltraCraft Reflex 3D printer, accessories, 6K LCD screen, and build plate. Photos by 3D Printing Industry.

Blueprint Studio software from HeyGears

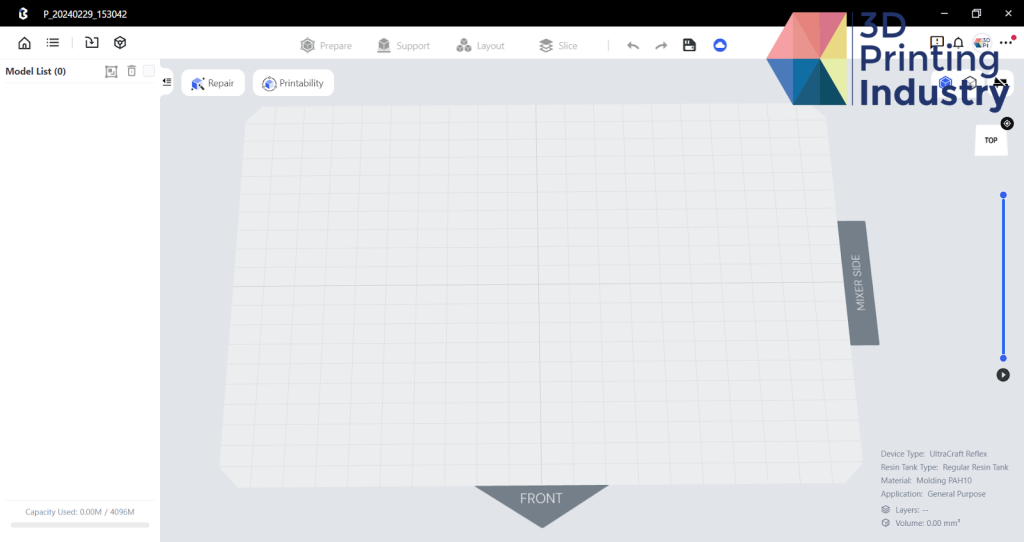

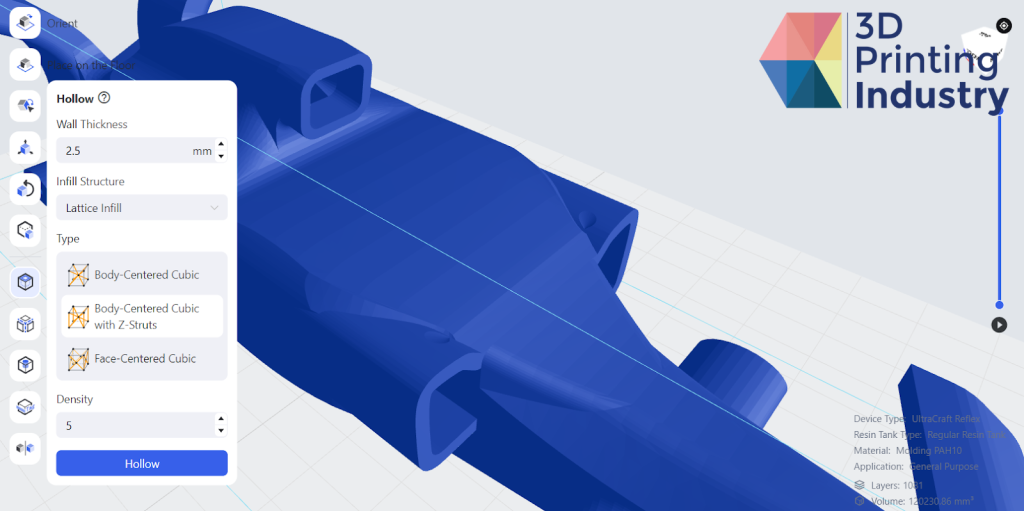

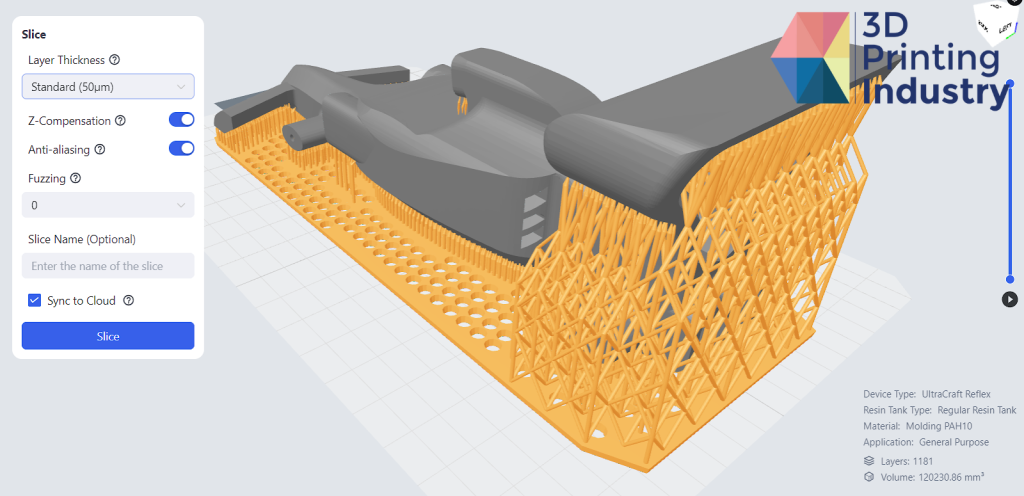

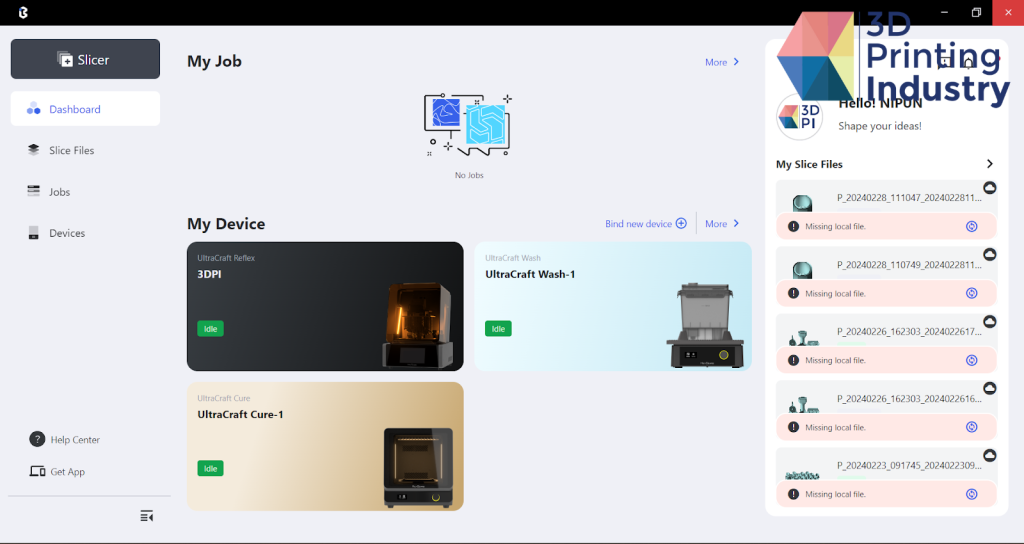

The HeyGears resin 3D printer is used alongside the Blueprint Studio slicer and 3D print management platform. This software stands out thanks to its user friendly interface, making it well suited to those new to resin 3D printing.

Through Blueprint Studio, users can easily slice models, generate support, and manipulate designs. A notable highlight is the “One Click-Slice” function, which automates tasks such as arranging, orienting, repairing, adding supports, and slicing the model. This streamlines the 3D printing process, a valuable asset for newcomers to resin 3D printing.

Blueprint Studio is also ideal for industrial-scale users wanting to run multiple Reflex 3D printers in a 3D print farm setting. The software’s print management feature enables multiple 3D printers to be controlled and monitored, with live updates on the 3D printing, curing and washing stages.

Those familiar with resin 3D printing will know the feeling of anxiety that often surrounds failed 3D print jobs. Finding that a failed 3D print has wasted valuable material is an experience most users would rather do without. Blueprint Studio’s printability analysis feature helps to mitigate these risks, offering peace of mind and the confidence that a part is suitable for 3D printing.

The tool allows users to verify the printability of a part before beginning a 3D print job. In our experience, the software effectively predicted and analyzed potential issues with support structures in advance. This allowed us to amend designs, and achieve successful 3D prints at the first time of asking.

Remote monitoring of the 3D printer, washer, and curing unit can also be achieved via the Blueprint Go app, which is compatible with both Android and IOS devices.

Blueprint Studio user interface, slicer, and print management page. Images by 3D Printing Industry.

An all-in-one resin 3D printing ecosystem

The Reflex Combo offers a full 3D printing and post-processing ecosystem, with washing and curing hardware delivered alongside the 3D printer.

After the 3D printing process has finished, it is essential to wash the resulting parts to remove any uncured resin which can be harmful and cause poor curing. Liquid solvents, such as Isopropyl alcohol, are usually used to achieve this.

The Reflex washing station employs a unique approach by creating a turbulent flow within the wash tanks. To achieve this, the entire tank gyrates, ensuring that the cleaning liquid fully contacts the 3D printed parts with enough force to wash away any unwanted residue.

Once a part has been thoroughly washed, it should then be cured in UV light to further harden the resin. This helps to stabilize the part’s material properties, enhance its surface quality, and improve its tolerances and accuracy.

We were impressed with HeyGears’ Reflex curing unit. The system’s chamber can heat up to 80℃, which was effective in optimizing curing across the part and enabling great surface finish. The unit also emits UV light at two different wavelengths, allowing different types of resin to be cured effectively.

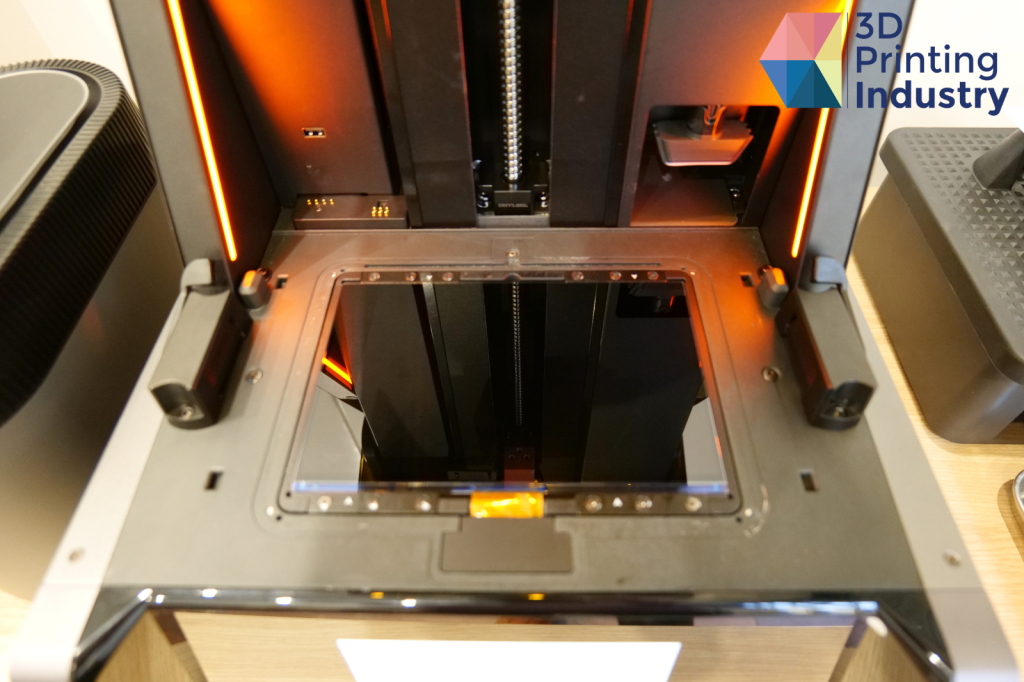

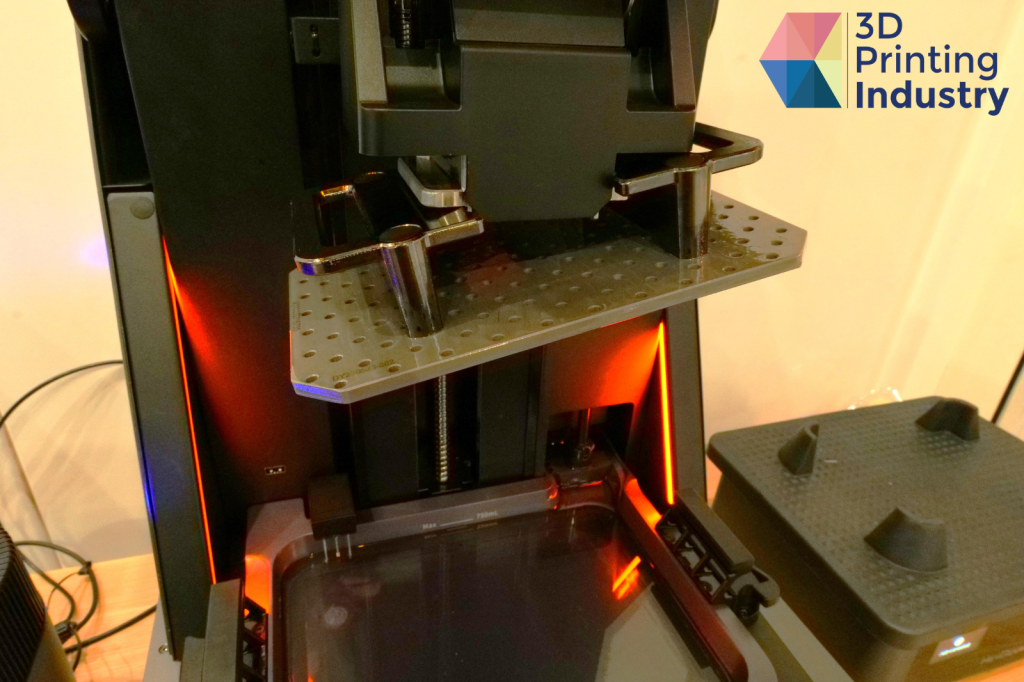

Our UltraCraft Reflex also came with a Pulsing Release Module (PRM). This optional add-on can be directly integrated with the 3D printer and is designed to reduce up to 50% of the peeling force per layer through high-frequency vibrations.

This allowed for faster 3D printing speeds as well as the need for fewer supports, which reduced material consumption. However, we found that the module did not substantially enhance surface quality compared to a standard resin tank. The HeyGears PRM can be purchased for $649 from the company’s online store.

The HeyGears washing station, curing unit, and Pulsing Release Module. Photos by 3D Printing Industry.

Benchmarking the UltraCraft Reflex

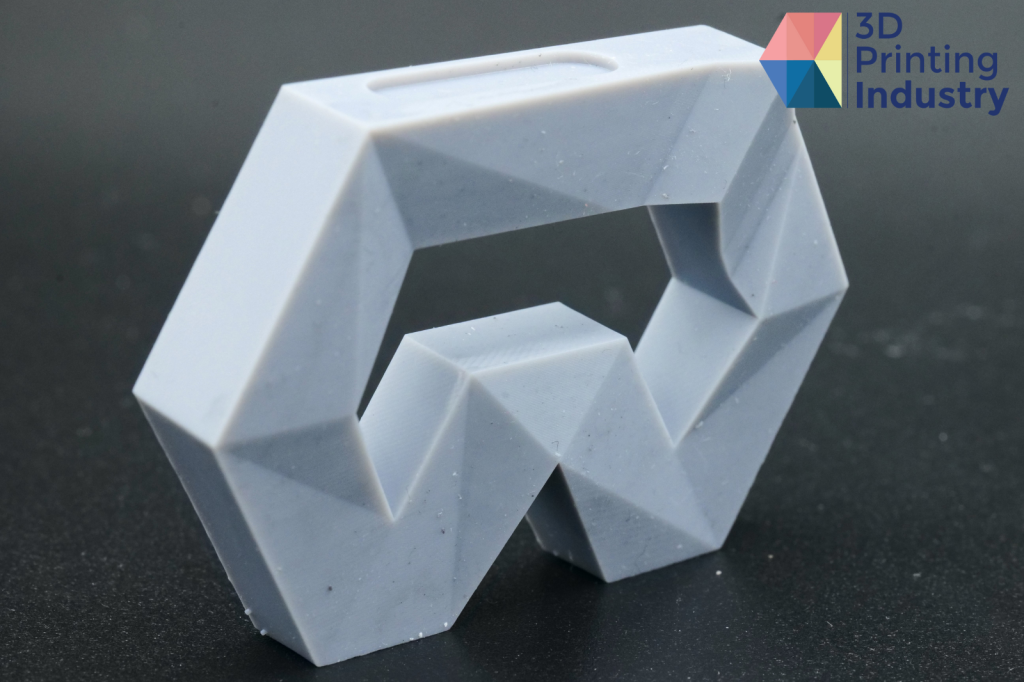

Our engineering team conducted 135 hours of testing on the UltraCraft Reflex. This included a range of 3D printed parts designed to benchmark the capabilities of the 3D printer. We started this process with the test file that came with the system, a model of the Blueprint Studio logo.

This model came out well with good surface quality. We were pleased with the detail of this part, despite some noticeable artifacts from the supports. This test also confirmed the functionality of the standard washing and curing cycles.

3D printed test file. Photos by 3D Printing Industry.

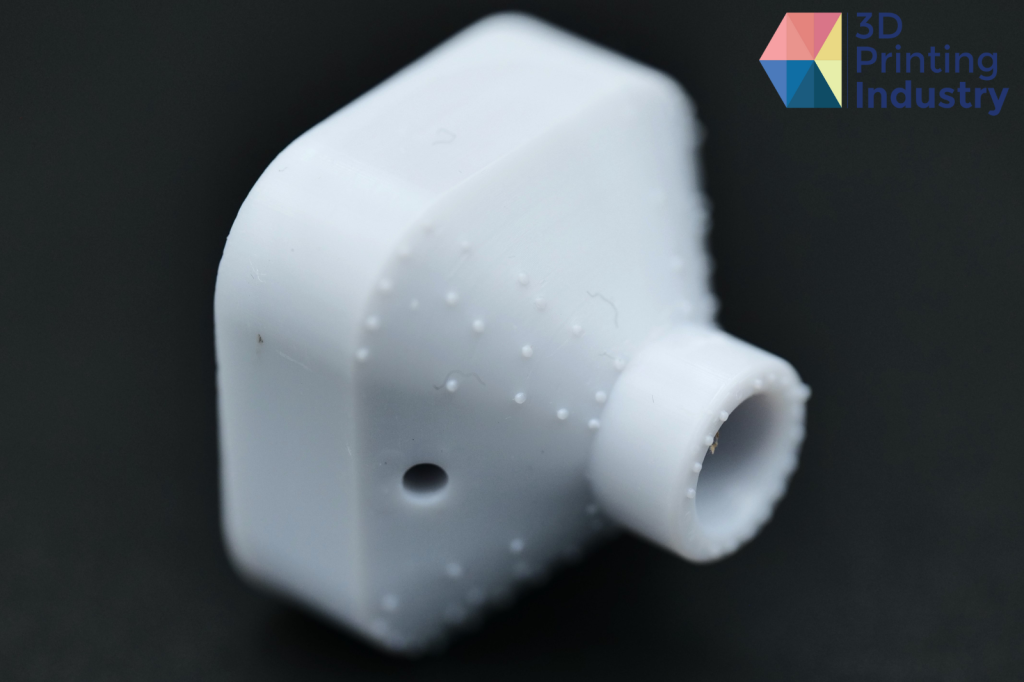

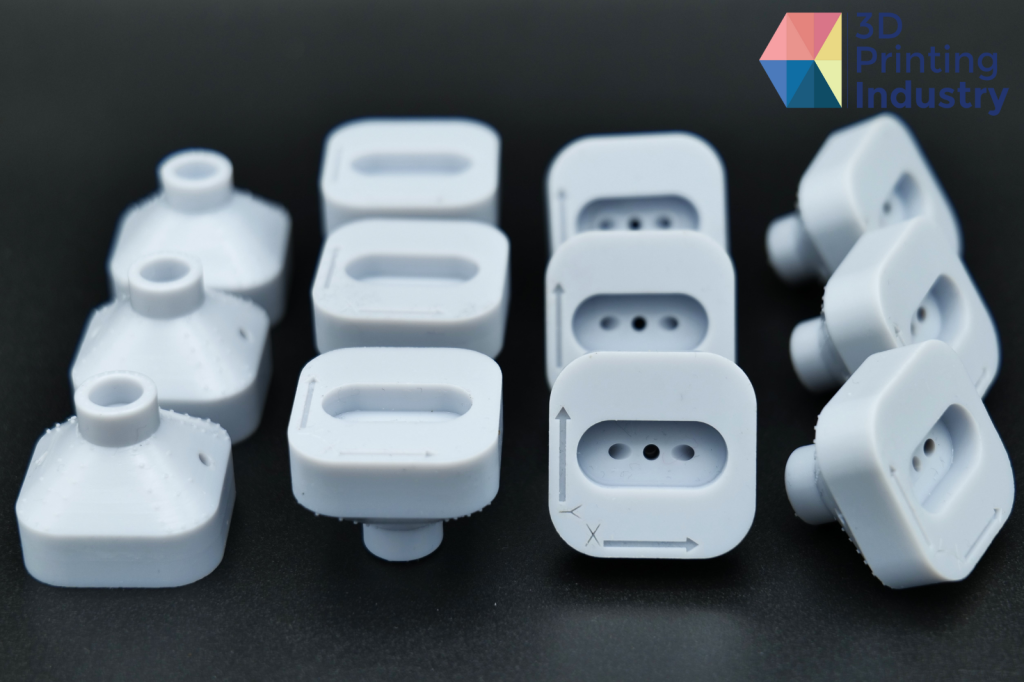

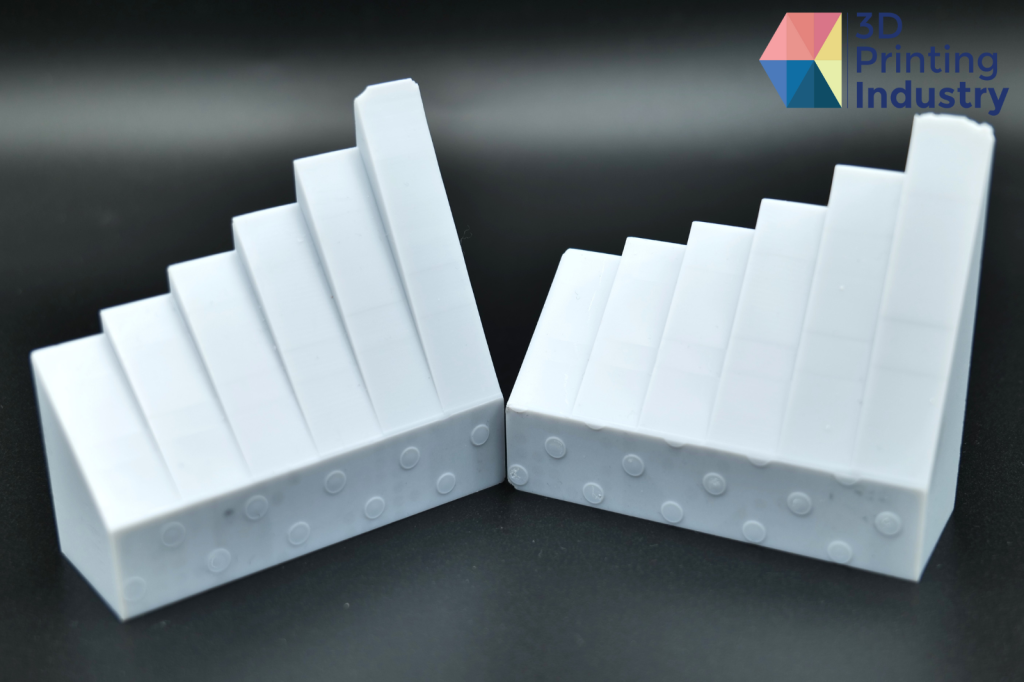

For prosumers wanting to produce batches of identical parts, good consistency and repeatability is key. To assess the repeatability of the UltraCraft Reflex, we printed a small part 12 times in batches of 6 and compared their dimensions to the original CAD model. An average deviation of 0.1 mm and a standard deviation of 0.05 mm can be viewed as a successful result.

The 3D printer performed well here, exceeding market standards. The overall average deviation of 0.0215 mm, while the standard deviation came in at just 0.0160 mm. These are impressive results for a consumer-level resin 3D printer, demonstrating both great accuracy and precision. All test pieces possessed good overall 3D print quality, with a smooth surface and no layer separation. However, some marks from the removal of supports remained visible after post-processing.

Repeatability test 3D prints. Photos by 3D Printing Industry.

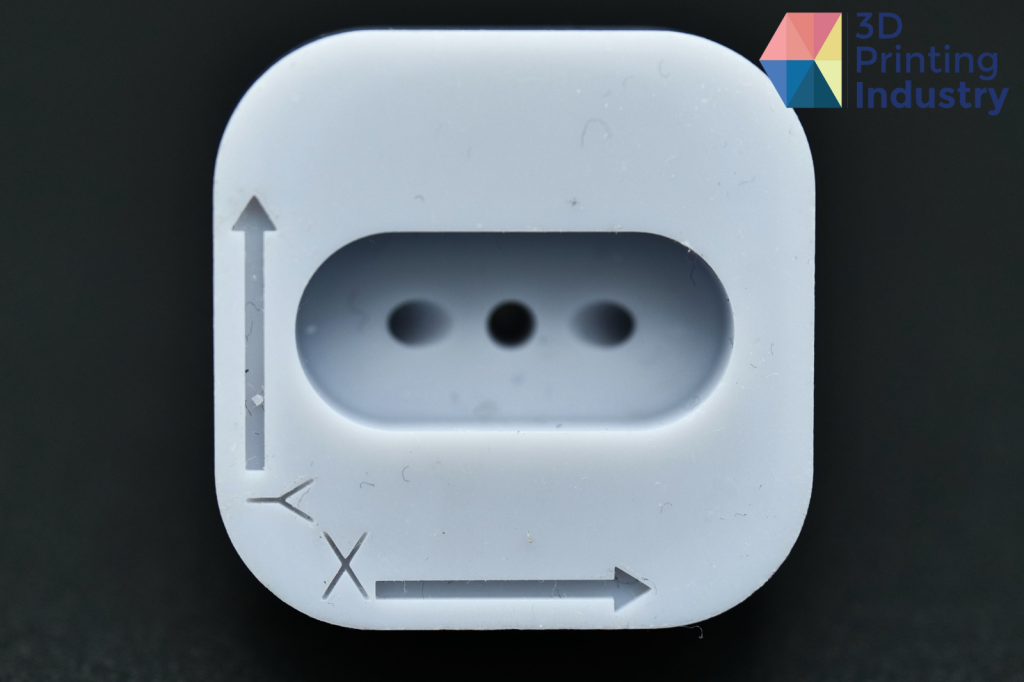

The UltraCraft Reflex stands out for its notable 3D printing volume, which is above average within the desktop resin 3D printer market. But can users 3D print parts that meet the full advertised dimensions?

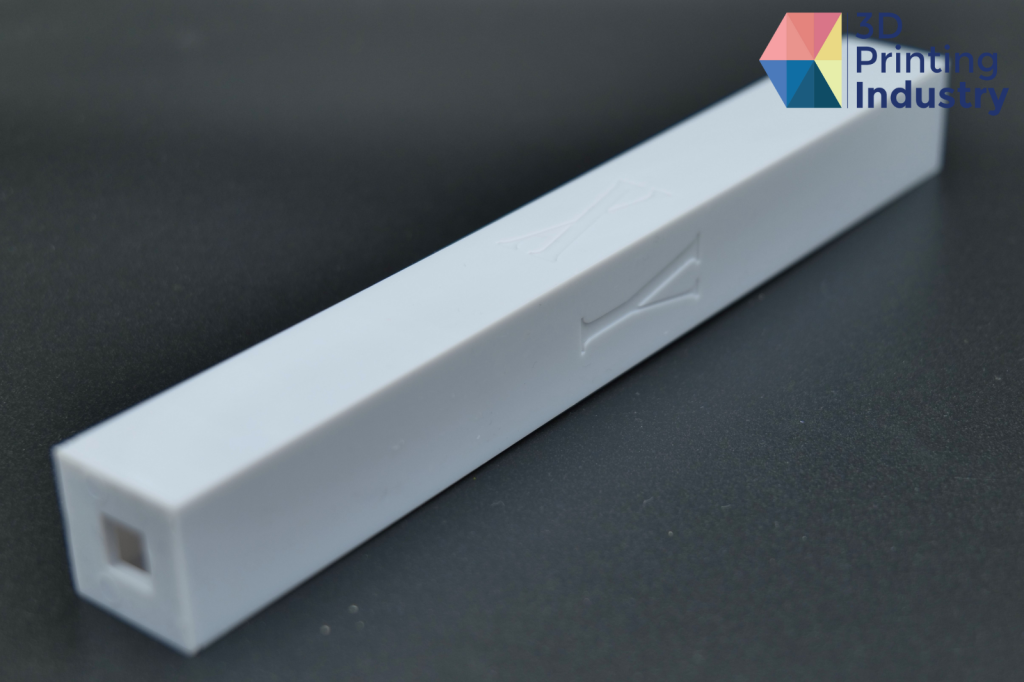

We first conducted a tower test to assess the advertised Z-axis of 220 mm. The HeyGears slicer restricted the part to 219.9 mm, with the tower successfully 3D printing to this height. It is common for 3D printers to restrict their dimensions slightly, with this representing a good result for the UltraCraft Reflex.

The tower part didn’t feature any shift between layers, with a smooth surface and good angles. However, we did notice a subtle elephant’s foot at the base of the tower. This phenomenon can be caused by poor adhesion of the first layer, and the initial layers being over-cured.

HeyGears offer no way to adjust exposure settings. As a result, we were unable to modify exposure time to reduce over-curing and remove the elephant’s foot. The inability to modify advanced settings may frustrate more experienced users wanting to perfect their 3D printed parts.

However, Blueprint Studio will normally automatically orient and support models so that they are raised above the build plate during 3D printing. While supports close to the build platform may be over-cured to achieve good adhesion, this will not impact the final part being 3D printed. Therefore, users should not encounter similar elephant’s foot issues unless they manually position the model flush with the build platform.

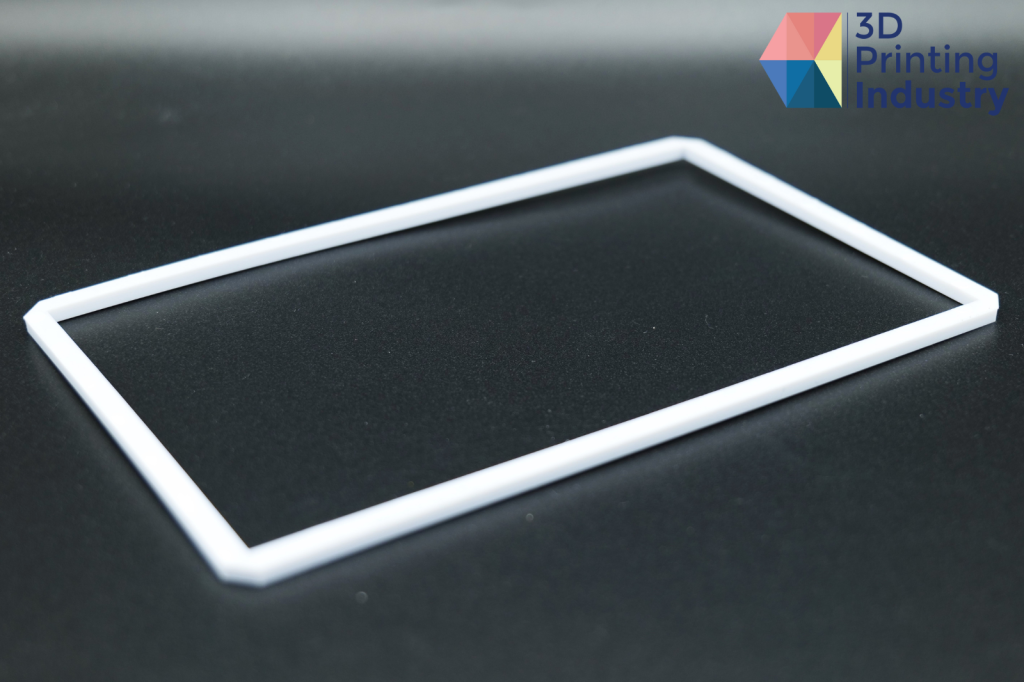

We also conducted a width test, which perfectly matched the advertised dimensions of 192 mm x 121 mm x 220 mm. However, as with the tower test, a slight elephant’s food was created. The model was also slightly warped after curing but possessed flat sides and no layer shifts.

3D printed tower and width tests. Photos by 3D Printing Industry.

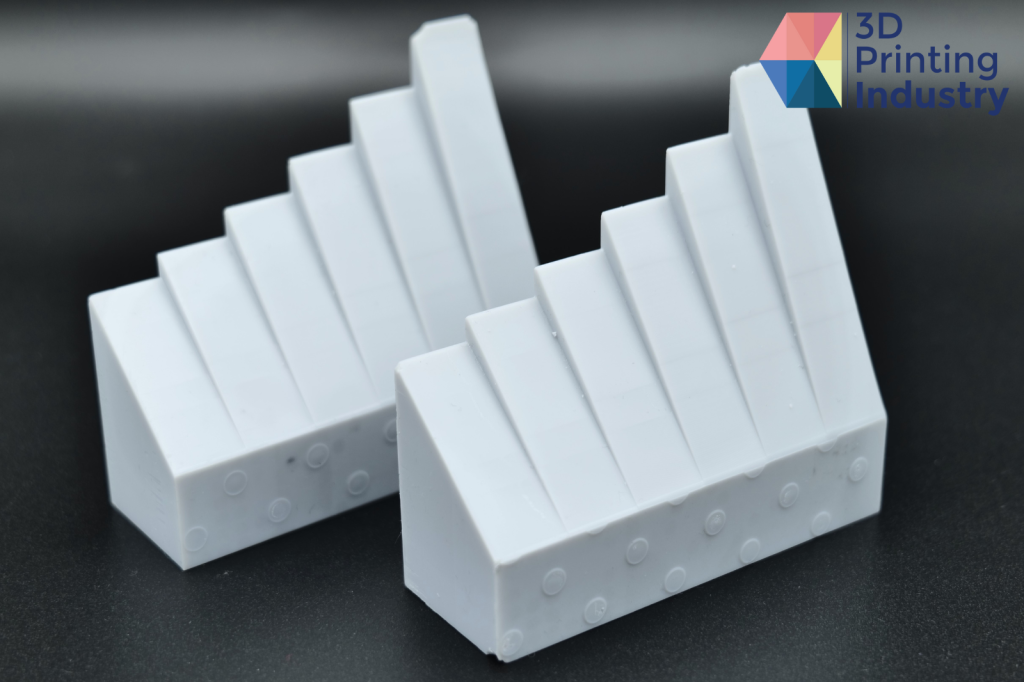

For users wanting to produce parts with complex geometries, the ability to 3D print overhangs is essential. In our overhang test, the UltraCraft Reflex performed very well, achieving consistent overhang results up to an angle of 65°. This surpasses the average performance of most other resin 3D printers, with consistent layer curing and no peeling effect.

However, the overhang models were tossed around inside the washing station during post-processing, causing their edges to chip. The gyrating nature of the HeyGears washing station could pose problems for users wanting to produce models with sharp edges and delicate features. To alleviate this issue, users can add a protective shell in the Blueprint software. 3D printed around the part, this shell protects the model during post-processing.

3D printed overhang tests. Photos by 3D Printing Industry.

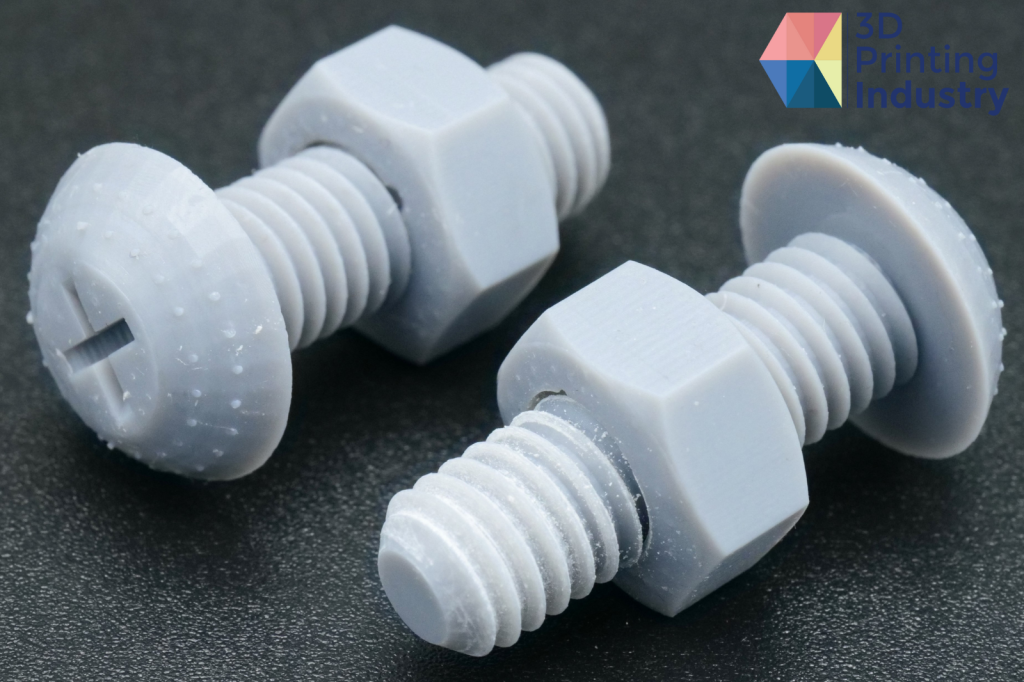

Prospective customers may also want to know whether the Heygears UltraCraft Reflex can produce functional models with very small dimensions and tight tolerances. To answer this question, we 3D printed a small nut and bolt model.

These parts ultimately possessed good detail, with no defects on the thread. As a result, the nut and bolt easily screwed together with no resistance, demonstrating good functionality.

3D printed nut and bolt models. Photos by 3D Printing Industry.

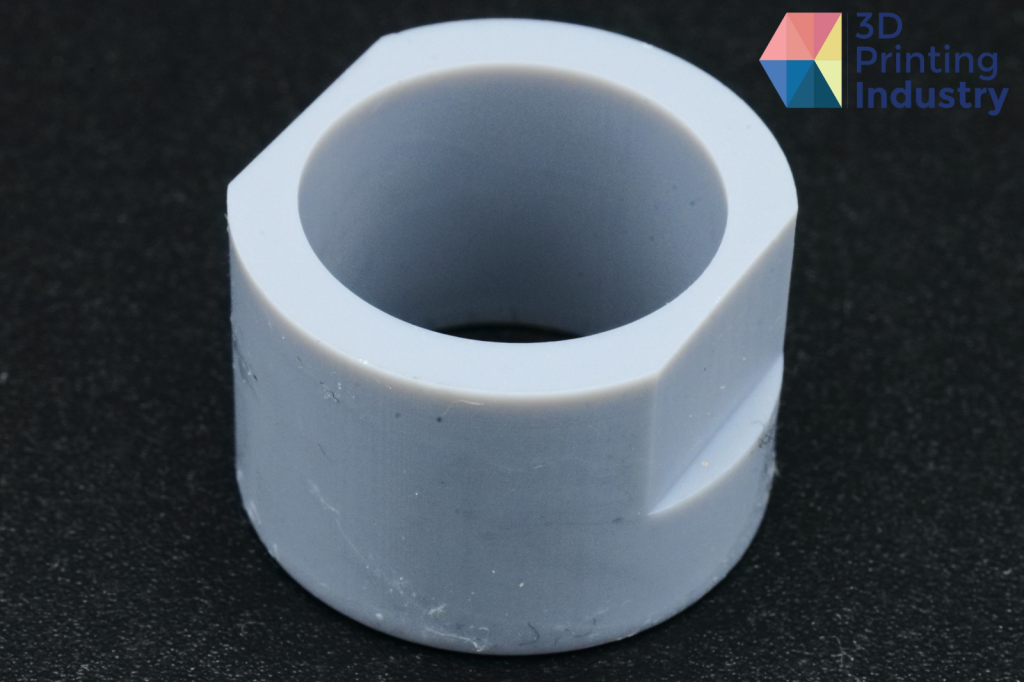

Next, we tested for ‘capability.’ Stemming from the 1970s US automotive industry, this concept uses statistical process control to assess the suitability of the 3D printer to mass produce parts.

Here, we 3D printed a model 150 times, 16 of which were then chosen at random and measured three times. From these measurements, the UltraCraft Reflex achieved a process capability score of 5.79. This indicates the 3D printer can produce accurate parts which have little variation from the target size.

However, the process capability index score of 0.41 is indicative of poor precision. This suggests that the 3D printer may struggle to achieve good consistency when conducting large production runs.

3D printed Capability models. Photos by 3D Printing Industry.

Testing UltraCraft Reflex use-cases

We next assessed how well the HeyGears UltraCraft Reflex resin 3D printer is suited to a range of real-world hobbyist, prosumer, prototyping and end-use applications.

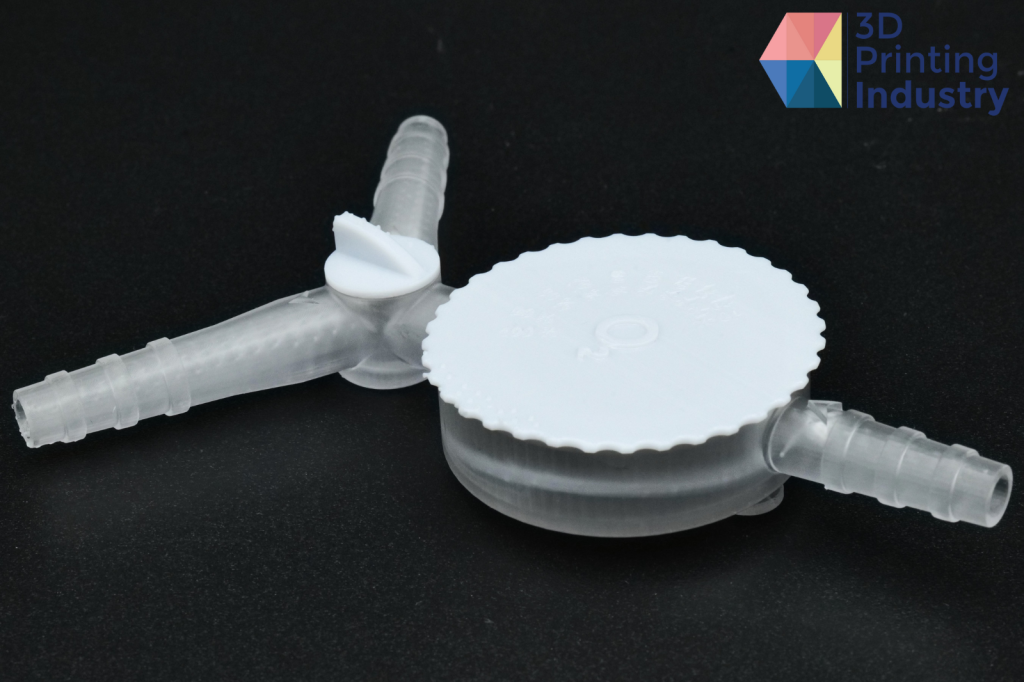

Resin 3D printers are frequently utilized for medical applications, thanks to their ability to produce durable and accurate parts. To assess the compatibility of the UltraCraft Reflex for such uses, we 3D printed a test design for an oxygen splitter and regulator.

This device is designed to distribute medical oxygen from a source to multiple patients. The body was produced using PAT10 resin due to its transparency, allowing for easy inspection of damage or internal debris. The regulator was 3D printed in PAU10 resin. This material was chosen due to its durability and the fact that it does not react to oxygen, ensuring the test part is functional and will have a long lifespan.

Ultimately, both sections of the 3D printed oxygen splitter came out well. The surface quality was excellent, with no visible layer lines or defects. The components fit accurately into the assembly, showcasing the 3D printers ability to meet dimensional requirements for intricate models.

UltraCraft Reflex 3D printed oxygen splitter and regulator test part. Photos by 3D Printing Industry.

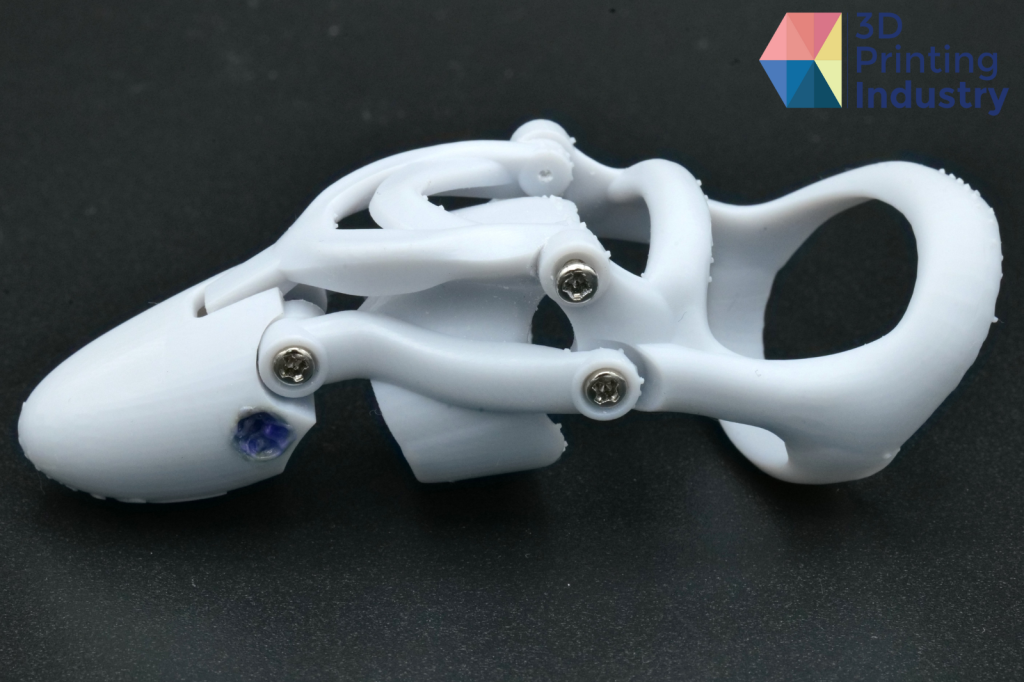

Staying within the healthcare theme, we also 3D printed a finger prosthetic, a customizable and cost-effective solution for individuals with partial or complete finger loss. This component was 3D printed in multiple sections, requiring good accuracy to ensure they fit together effectively. Ultimately, the 3D printer performed well here. The prosthetic fit together easily and possessed good strength and durability.

UltraCraft Reflex 3D printed finger prosthetics. Photos by 3D Printing Industry.

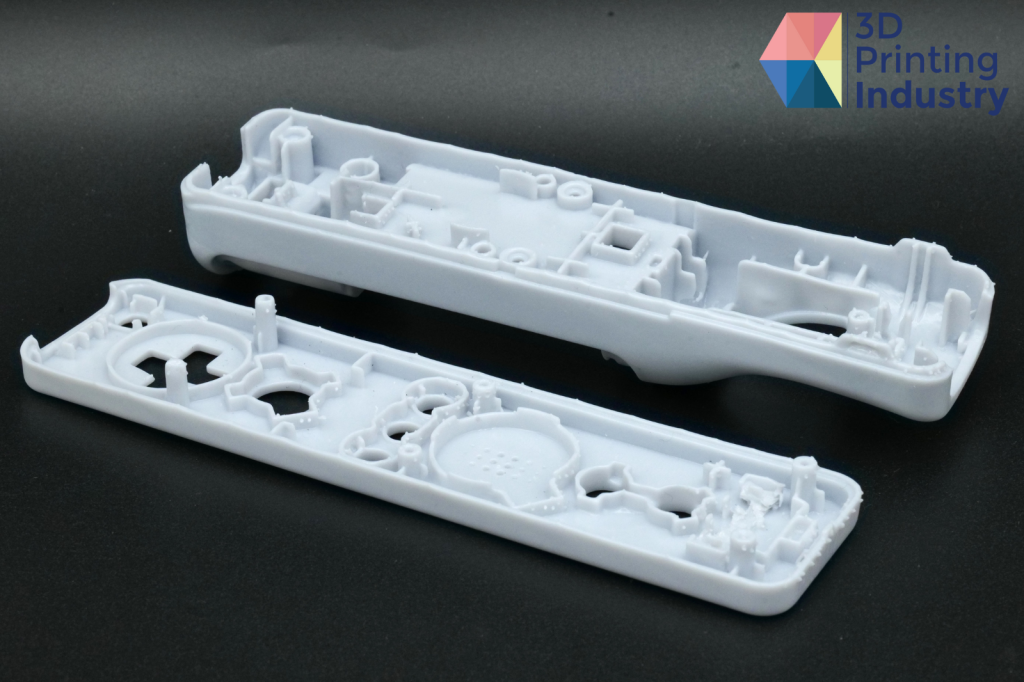

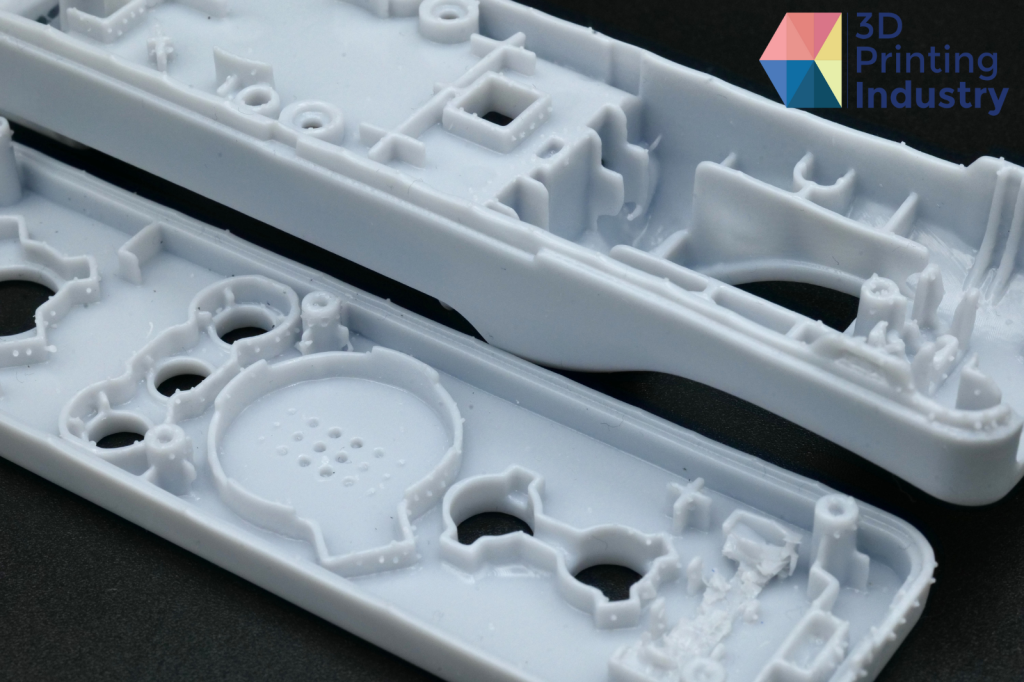

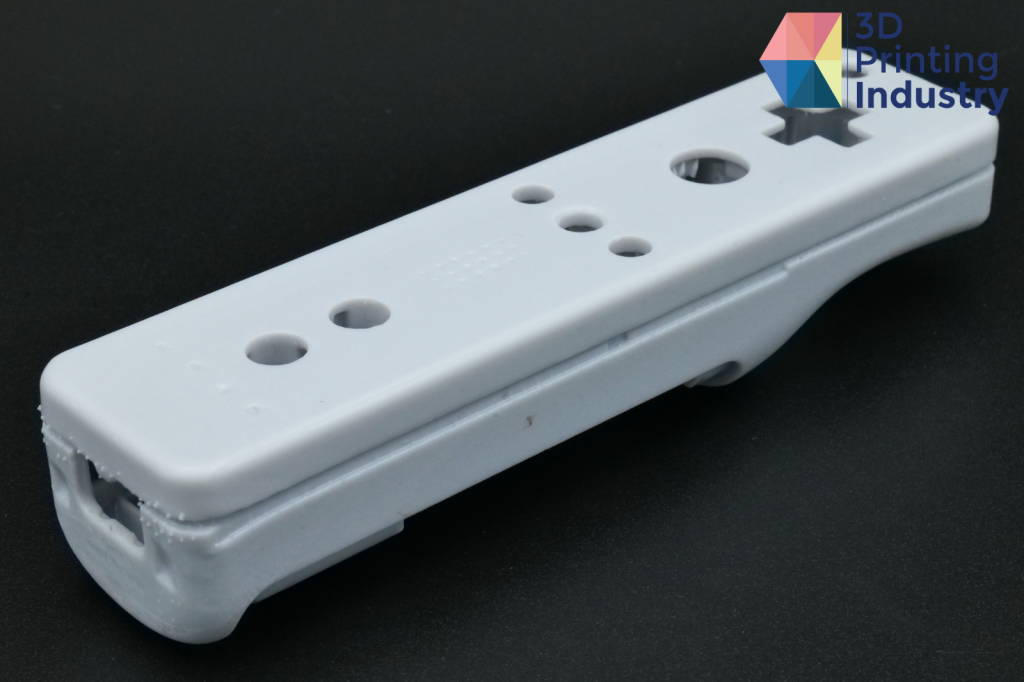

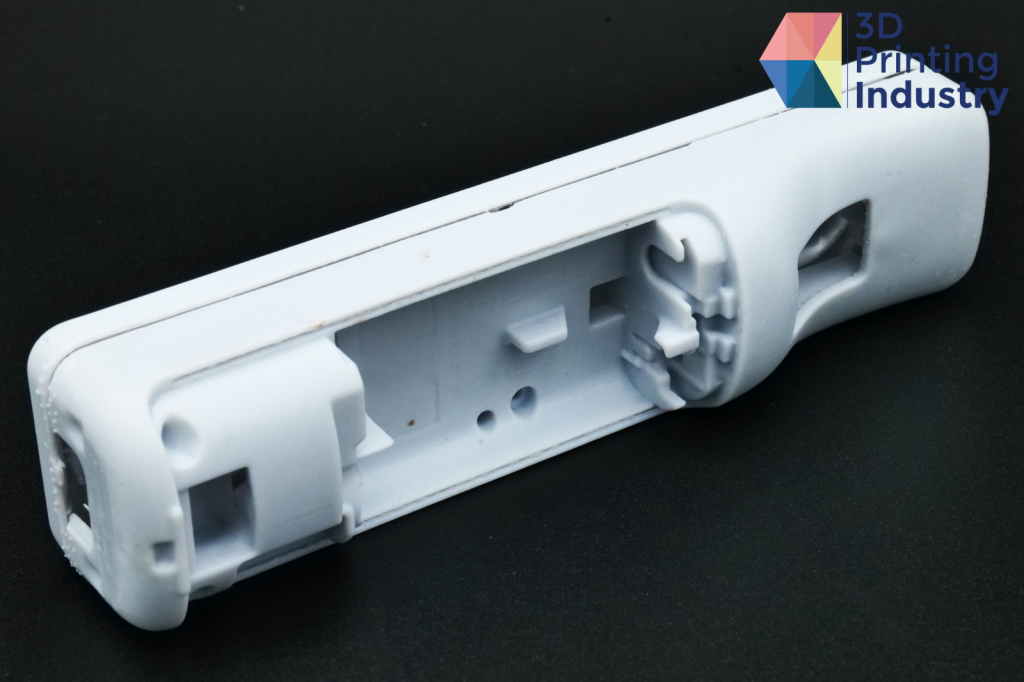

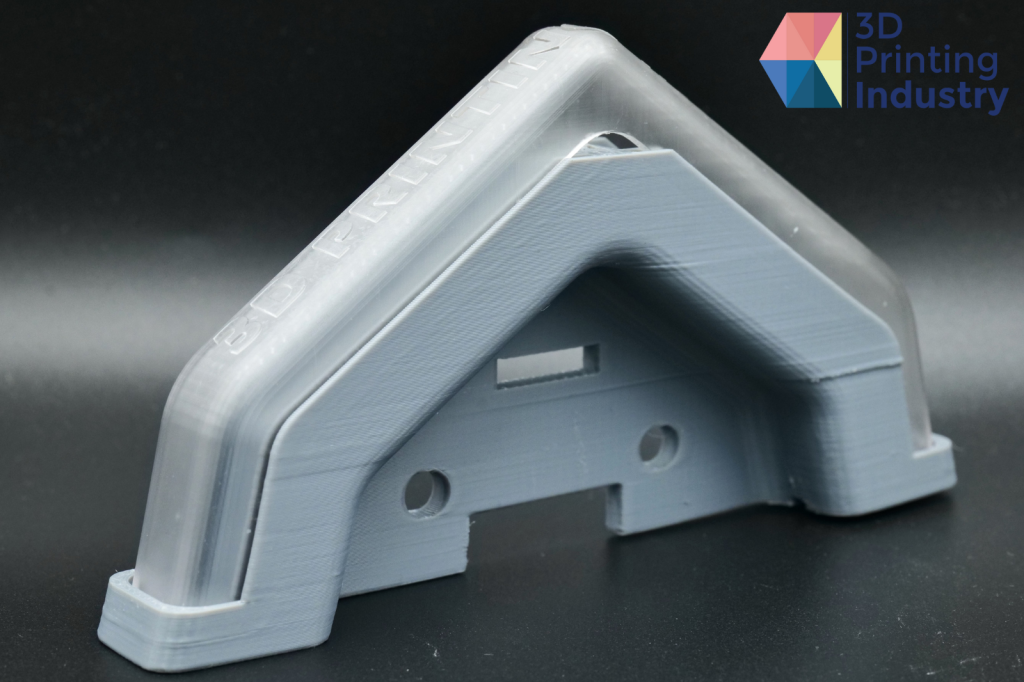

Engineers and prosumers may wish to conduct reverse engineering or produce functional parts, such as casings, which are traditional manufacturing using injection molding. To assess the 3D printer’s ability to meet these demands, we produced the outer shell of a Nintendo Wii remote from a 3D scan.

This 3D print was successful, yielding good surface quality with no visible defects. The internal wall features showcased good detail, with both sections fitting together nicely. The washing station and curing unit worked effectively here, ensuring no uncured resin remained within the small holes and crevices.

3D printed Wii remote. Photos by 3D Printing Industry.

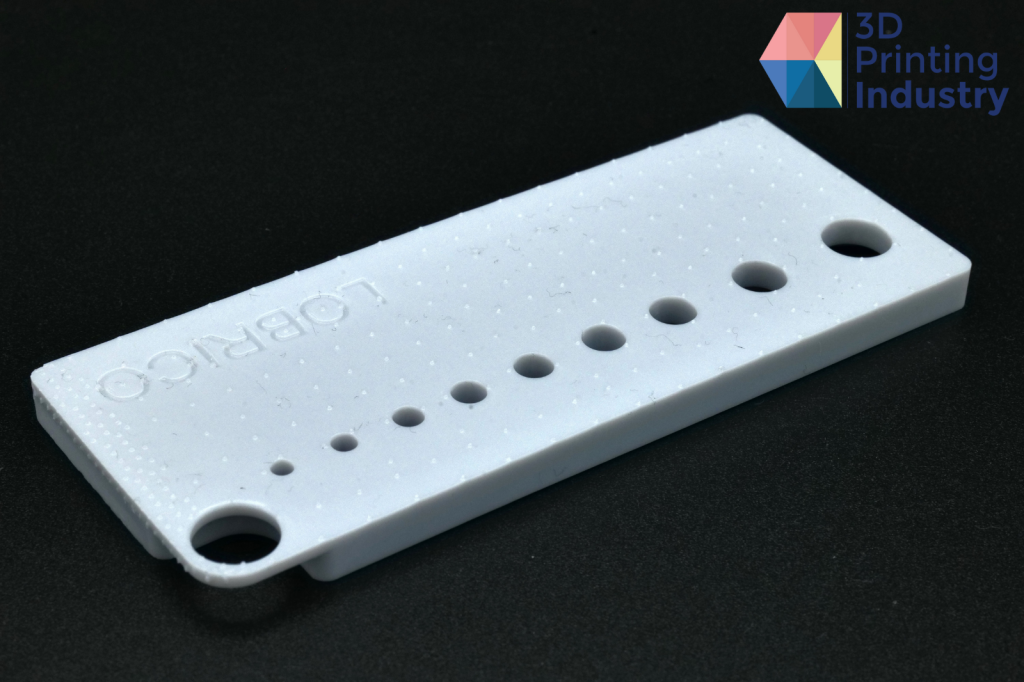

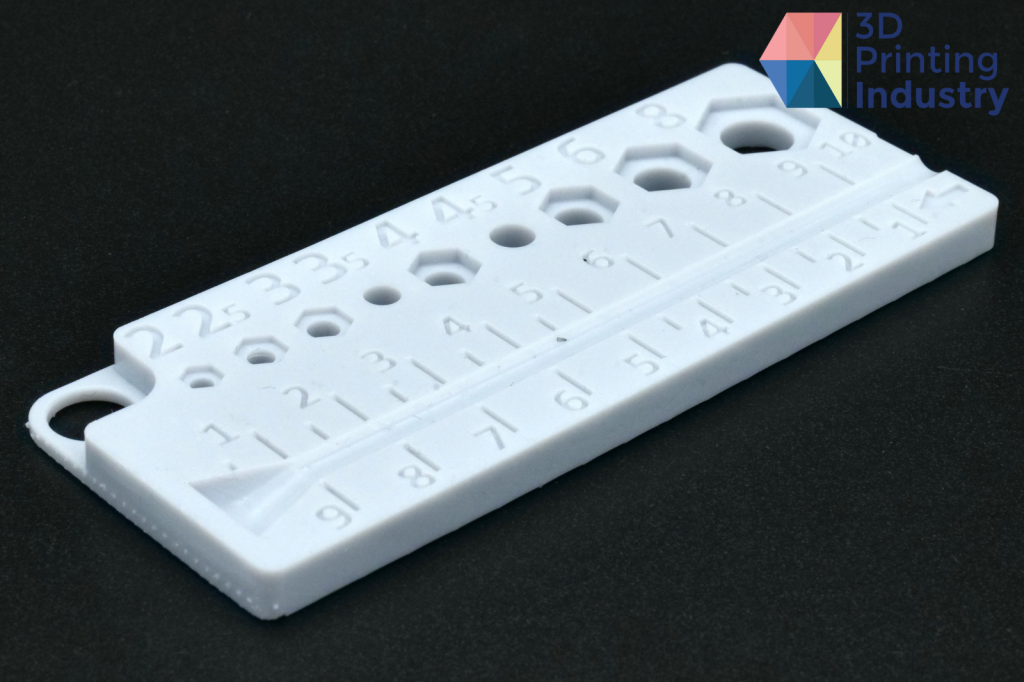

Can the UltraCraft Reflex produce components that are both accurate and tough? To find out, we next 3D printed a metric thread gauge using the company’s PAU10 resin, which features high tensile strength. These tools are often used in workshops and need to be robust while offering a high level of accuracy.

The 3D printed part was clean and required minimal post-processing. It accurately reflected the size of the bolts, indicating that there was no shrinkage after curing. The holes also came out well-rounded, ensuring that this 3D printed tool offers good functionality.

3D printed metric thread gauge. Photos by 3D Printing Industry.

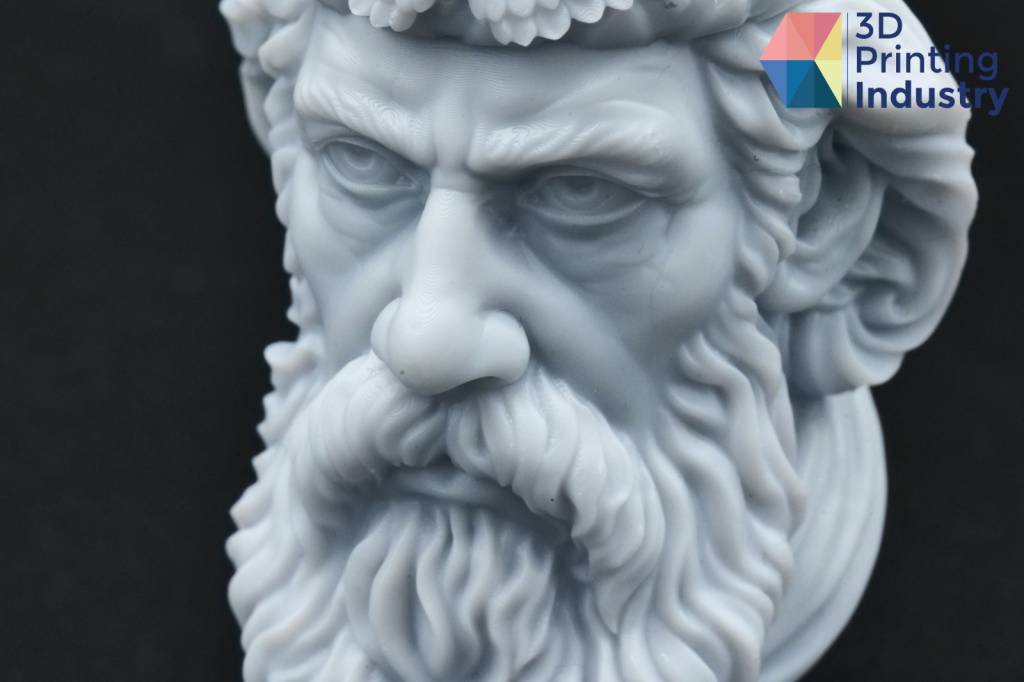

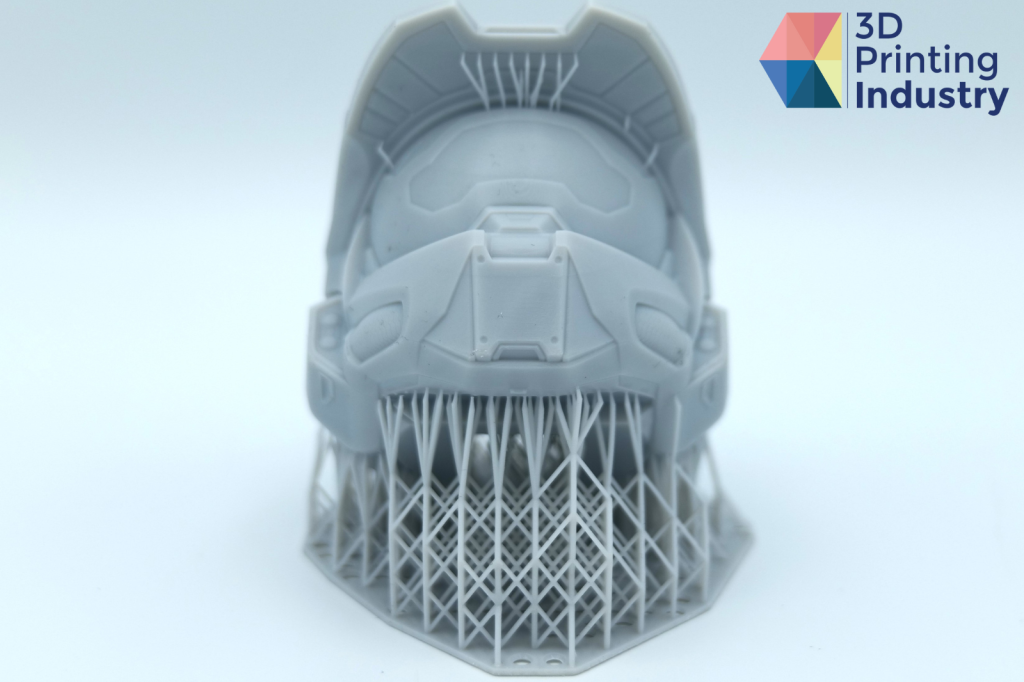

A popular application of desktop resin 3D printers is the production of miniature models and figurines that possess fine details. To find out whether HeyGears’ 3D printer is a good choice for users targeting these applications, we 3D printed four different models with unique geometries. Given that each model featured small and intricate details, which would be easily damaged within the washing tank, we 3D printed them inside a protective shell. This is something we would recommend for most delicate models, given the rigorous nature of the part-cleaning process.

These test pieces highlighted the 3D printer’s ability to produce parts with fine details and clean surfaces. The parts were aesthetically pleasing, and certainly meet the requirements of users wanting to produce high-quality miniatures.

3D printed miniature models and the protective shell. Photos by 3D Printing Industry.

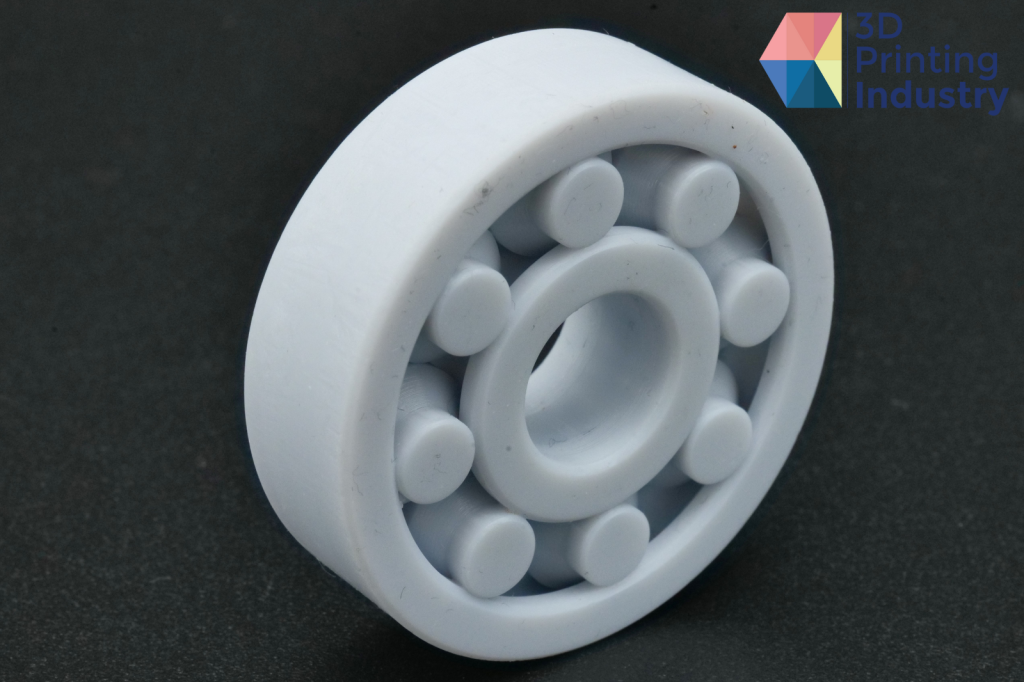

Next, we assessed whether the resin 3D printer is capable of producing mechanical parts as a single piece. The print-in-place model we chose was a bearing, which required high tolerances in order to function correctly.

Unfortunately, while overall 3D print quality was good, the model did not function as intended. The UltraCraft Reflex cured resin within the gap between the rolling elements and the casing, making it impossible to rotate the bearing without it breaking.

3D print-in-place bearing. Photos by 3D Printing Industry.

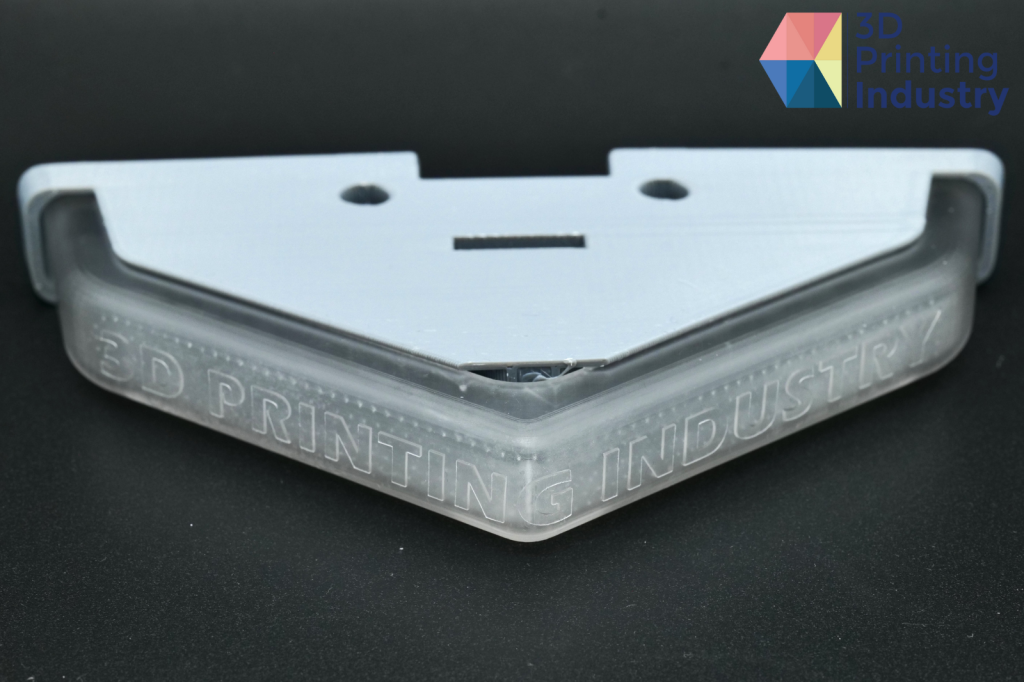

Finally, we sought to assess the suitability of the HetGears 3D printer for engineers and designers wanting to prototype parts. The model we chose was a motorcycle tail light, which required a translucent material that could uniformly refract light.

The HeyGears PAT10 resin was perfect for this application, thanks to its rigidity, transparency and resistance to chemicals and weather. This part came out perfectly. There were no surface defects and the supports were easy to remove. The model also possessed perfect dimensional accuracy, confirming that the 3D printer can produce accurate prototype parts.

3D printed tail light lens. Photos by 3D Printing Industry.

An impressive addition to the desktop resin 3D printer market

Ultimately, the HeyGears UltraCraft Reflex stands out as a great addition to the desktop resin 3D printer market. Its user-friendly workflow and affordable price point make it well-suited for those new to resin 3D printing. Thanks to its generous build volume and impressive accuracy, the 3D printer also appeals to more experienced users seeking full-scale, high-quality parts.

The Blueprint Studio software was excellent, offering a streamlined and straightforward experience. What’s more, the integrated washing station and resin unit worked well, allowing for easy, end-to-end 3D printing and post-processing.

While the washing station’s turbulent flow process is effective in cleaning uncured resin from hard to reach places, it can damage more delicate components. Therefore, we recommend that such parts be 3D printed within a protective shell.

On the whole, the 3D printer performed well in our testing, demonstrating an ability to fabricate small, detailed, and functional parts. It easily met the advertised dimensions and performed especially well for repeatability.

However, some problems were encountered in terms of capability, suggesting that it may not be the best option for users conducting high-volume production runs. What’s more, our failure to fabricate a print-in-place model was somewhat disappointing.

More experienced users may also be frustrated by the inability to adjust exposure settings. Adding the ability to manually change parameters such as these would elevate the experience for those wanting to fully optimize the performance of their 3D printer, and mitigate surface defects such as elephant’s foot.

Despite these small areas for improvement, HeyGear’s debut into the consumer resin 3D printer market represents a good value option that is capable of achieving high-quality results. Easy to use, the UltraCraft Reflex is an ideal option for those wanting a hassle-free resin 3D printing experience.

Technical specifications of the UltraCraft Reflex

| 3D Printing Technology | LCD Resin 3D printer |

| Build Volume | 192 mm x 121 mm x 220 mm |

| Dimensions | 400 mm x 420 mm x 573 mm |

| Maximum Resolution | 6000 pixels |

| Light Source | COB LED |

| XY Precision | 33 μm |

| Accuracy | ± 16 μm |

| Layer Thickness | 30 μm – 100 μm |

| 3D Print Speed | 27 mm/h (with a layer height of 50 μm |

| Wight | 25 kg |

| Software | Blueprint Studio |

| Connectivity | Ethernet / USB / Wi-Fi |

| Voltage | 100-240 V AC, 50/60 Hz |

| Rated Power | 350 Watts |

| UI Languages | English; Chinese |

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the HeyGears Ultracraft Reflex resin 3D printer. Photo by 3D Printing Industry.