German railway company Deutsche Bahn (DB) has revealed plans to expand its 3D printing production.

The multinational company has already voiced aims to 3D print spare parts and is part of the ‘Mobility goes Additive’ network to advance this goal.

Headquartered in Berlin, Deutsche Bahn states it has already 3D printed 1,000 parts with expectations for that number to double to 2,000 by the end of 2017. However, the German company has ambitious plans to scale this number up even further to 15,000 by the end of 2018.

“Our trains are expected to roll”

Uwe Fresenborg, CEO of DB Fahrzeuginstandhaltung (Vehicle Maintenance) explains the company’s 3D printing philosophy,

For the maintenance of our vehicles we need immediately available spare parts. Our trains are expected to roll, 3D printing helps us in doing so. Printing is faster, more flexible and cheaper than conventional manufacturing processes, and the vehicles are available again in a very short time and are used for our customers.

Fresenborg spoke at last month’s Materialise World Summit in which he stated the key for advancing 3D printing is expanding the material database.

Mobility goes additive

Mobility goes Additive is a network of companies in the mobility and logistics business looking to advance the application of additive manufacturing. Deutsche Bahn began using 3D printing back in 2015 to create a simple coat hook and the technology clearly piqued its interest.

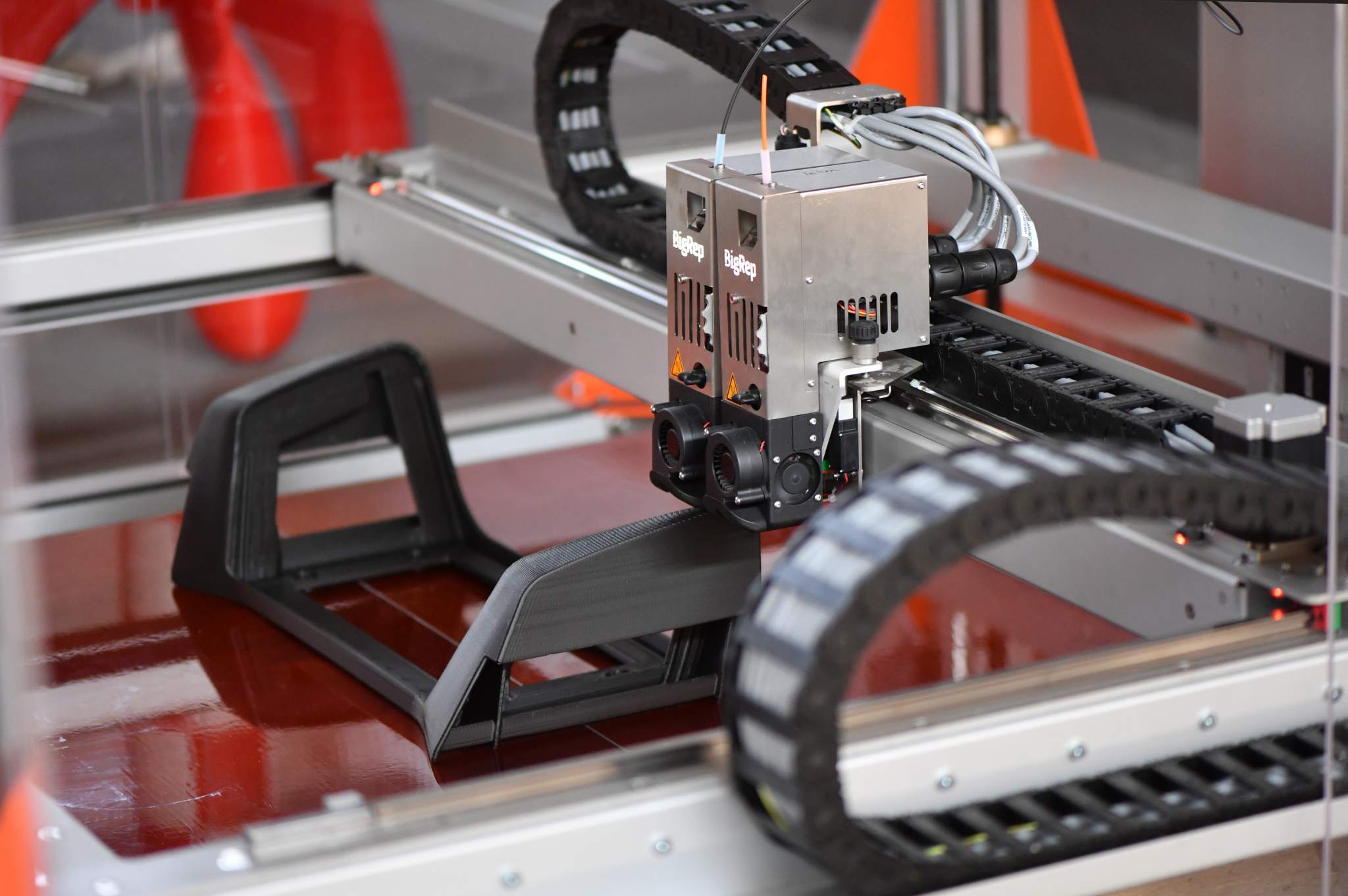

Since then, Deutsche Bahn has partnered with software company 3YOURMIND and German 3D printer manufacturers BigRep. Deutsche Bahn has also begun trial use of Local Motors 3D printed autonomous shuttle bus, Olli.

Innovative use of 3D printing

Deutsche Bahn is not just using 3D printing to make the same parts in a new way, the railway company is also harnessing the advanced manufacturing possibilities to create novel new designs.

Deutsche Bahn has explored the use of 3D printing to create metal parts with braille in order to help the disabled navigate. In Berlin’s Central railway station, Deutsche Bahn has employed 3D printing for individualized handicapped signs for handrails. Additionally, the company is encouraged by the idea of reducing the need to store a large inventory of spare part stock.

The 3D Printing Industry Awards are taking place this month in London and there is still time to place your votes to decide the winners.

For the latest 3D printing news, subscribe to our newsletter and follow us on twitter.

Featured image shows a Deutsche Bahn train.