Xaar, a UK-based developer of inkjet printing technology, has announced the launch of its latest printhead, the Xaar Irix.

Powered by the company’s ImagineX platform and based on the previously released Xaar 128 device, the new Xaar Irix is designed to be easy-to-use and lightweight with a compact footprint.

The printhead comes in two different variants: Core and Pro. The former is for applications based on oil or solvent-based inks, including coding, marking, and functional fluids. The latter, on the other hand, is more suitable for demanding applications with a focus on print quality. This includes product printing and 3D printing.

Graham Tweedale, General Manager of Xaar’s printhead business unit, said, “We are delighted to be launching the Xaar Irix as the next printhead from our ImagineX platform. Designed with the user in mind, the Xaar Irix ensures accurate, reliable, and easy printing for coding and marking, wide-format graphics and additive manufacturing applications and provides efficient, effective and impressive results, time after time.”

Over 30 years of inkjet with Xaar

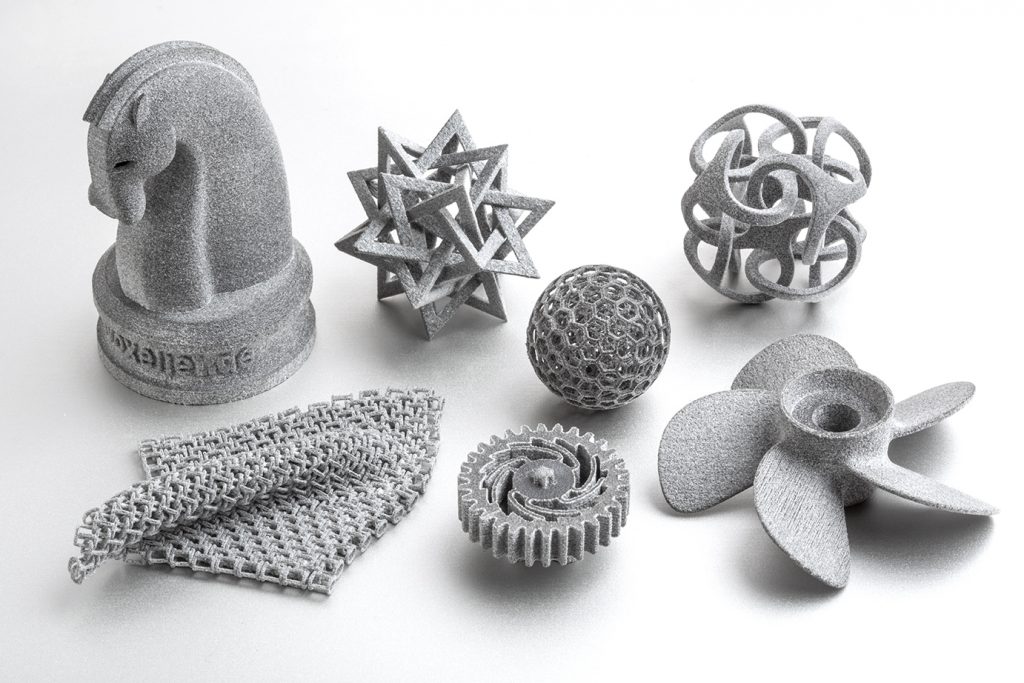

Xaar has been a specialist in inkjet printing technologies for over 30 years, and now offers an extensive portfolio of printheads for applications such as inkjet-based 3D printing. The company’s devices have seen use in a wide variety of additive manufacturing processes, including Photopolymer Jetting (PPJ) and Binder Jetting. But Xaar’s involvement in the 3D printing sector goes beyond this.

In fact, just last year, the firm introduced a 5-step service for the evaluation of 3D printing materials. The service is designed to aid companies focusing on the jetting of high viscosity fluids.

The company has also previously formed a 3D printing business with Stratasys, a manufacturer of industrial 3D printers. The joint firm, named Xaar 3D Limited, holds all of Xaar’s High Speed Sintering (HSS) assets – a technology invented by Neil Hopkinson, Xaar’s Director of 3D Printing since 2016. Stratasys has since increased its stake in Xaar 3D from 15% to 45%.

More recently, HSS was used as the basis for Stratasys’ new Selective Absorption Fusion (SAF) process, which now powers the company’s H350 3D printer.

The Xaar Irix

The new Irix features Xaar’s tried-and-tested AcuDrp technology, which is designed to ensure each of the printhead’s nozzles is calibrated with precise drop placement. AcuDrp allows for a wider operating window, increasing the reliability of the device as well as its uptime over a variety of operating conditions. Irix comes factory calibrated to be compatible with both solvent inks and oils.

The system reportedly delivers both uniform drop velocity and volume, which is crucial for achieving high-quality images for applications such as coding and marking, especially at longer print distances. Each of the nozzles has been individually lasered with a nozzle density of 185 nozzles per inch.

Measuring 37.2 x 11.3 x 40.8mm, the printhead has been equipped with a robust architecture. The print swathe width sits at 17mm and the simple fluid and electrical connections make for easy integration, whether it be with a 3D printer or functional fluid dispenser. Irix offers a maximum firing frequency of up to 8.3 kHz.

Additionally, the printhead is designed to have a long service life. There’s no need to replace any cartridges, minimizing the product’s environmental footprint and waste. This also serves to improve the sustainability credentials of systems that implement the Xaar Irix.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Xaar Irix printhead. Photo via Xaar.