A 3D printer may have dimensional limitations, but these can be overcome through design. So, while I might simply be using my Ultimaker 2 Extended to 3D print the biggest objects I find on Thingiverse, one creative and passionate designer might just 3D print something capable of beating a land speed world record.

The fact that it is an RC car world record does not make James Beswick’s goal of racing his 3D printed missile to 202 miles an hour any less impressive. In the latest Ultimaker Story, Sander van Geelen tells the tale of high-speed RC-car drag racing and how his discovery of 3D printing opened up a new world of possibilities for his passion.

“It sped up the building process significantly and opened so many more exciting possibilities. I think I can honestly say I’d be lost without my Ultimaker in my life,” Beswick said. “For me the only hard part of the process is the waiting. I don’t always get the parts perfect first time but with the nature of 3D printing it’s so simple to go back to the design and make slight changes, then try again. The process is as simple as: Imagine, Design, Print, Enjoy!”

He chose to use an Ultimaker 2 Extended because of the taller volume, which enabled him to print larger and more streamlined dragster parts. The open filament systems also allowed him to try several different materials. He eventually settled on a PLA/PHA blend, which offered more flexibility than pure PLA. Likely, although he does not openly state it, it was colorFabb’s filament, as they make a widely used PLA/PHA blend.

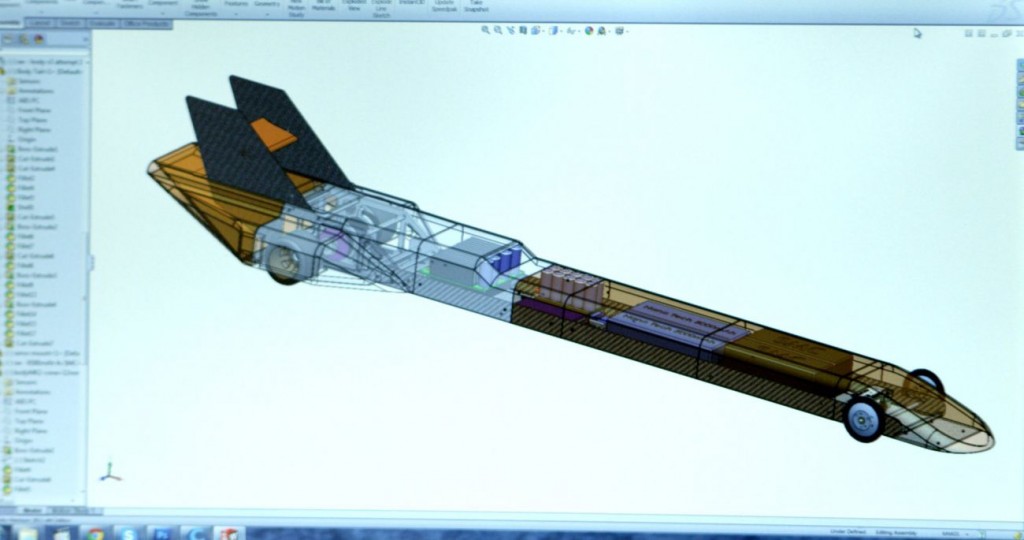

Beswick digitally designed the whole concept and then 3D printed several parts, along with the whole body-shell. The rear wing, servo holders, controller mounts, battery and cable clamps, and even shock absorbers for the electronics were 3D printed.

Perhaps the single biggest advantage of implementing desktop 3D printing in the design and prototyping process is the possibility to (relatively) rapidly and affordably re-print broken parts and new parts to evolve the design after testing it. As the speeds of the car increase, subtle changes would be needed in the aerodynamics to make sure the car stays firmly on the ground at high velocity. “I’ve learnt through testing that stones at high speed versus PLA are a deadly mix, so in the next version of the body I’ll be printing I’ll be addressing a few weak spots,” he added.

In the process he might even come up with some tips for another partially 3D printed, full-size, world land speed record seeker: the Bloodhound Project. It’s just a matter of size.